ASSURANCE

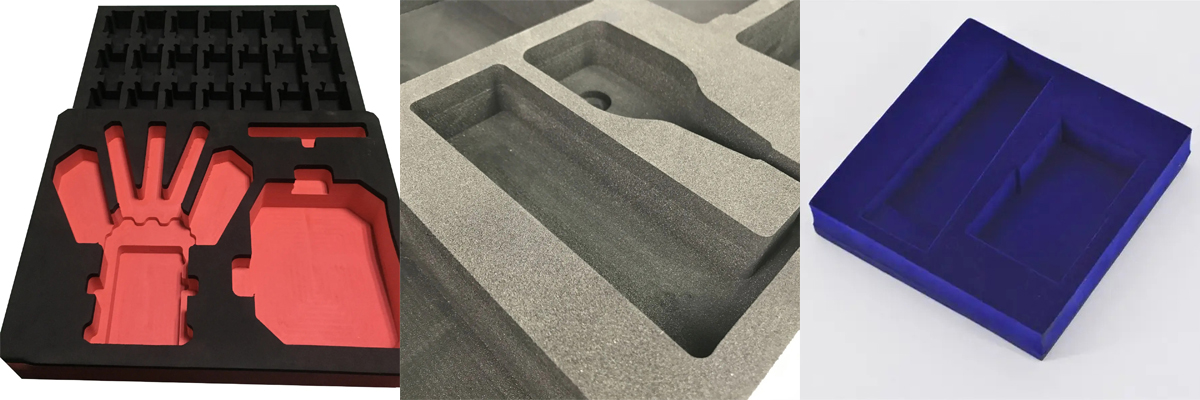

When it comes to EVA foam, the first thing that comes to mind is its compressive, tear-resistant and scratch-resistant characteristics. EVA has become an indispensable product assistant in the packaging industry with a series of excellent properties of elasticity, light weight and fast pressure-sensitive fixation.

Because of this, how to better cut materials while retaining the high-quality characteristics of EVA foam, rubber-plastic sponge and other packaging materials is also a problem that packaging industry manufacturers have to consider.

Now, whether in industry or in life, the use of foam sponge is more and more, and the scope of application is also more and more extensive. As a new environmentally friendly material, EVA foam has excellent performance. It not only eliminates the shortcomings of ordinary foam that is fragile, easy to deform, and has poor recovery; Plasticity, good toughness, excellent recycling and environmental protection characteristics; at the same time, it has good chemical properties, strong impact resistance, and is also a very good packaging material.

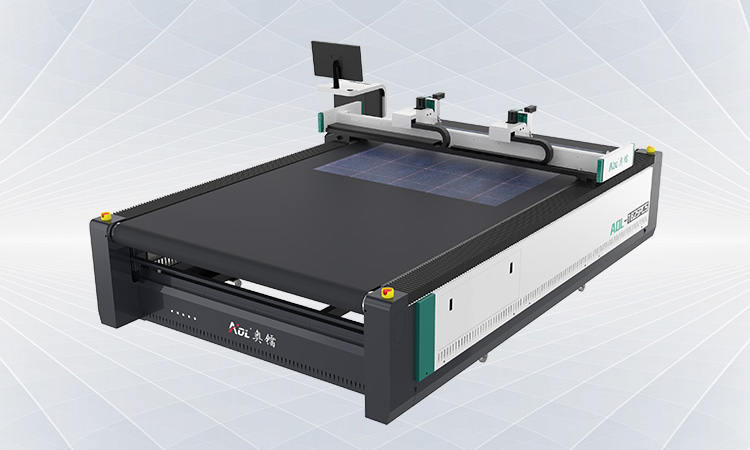

Since this material has such a wide range of applications, how is it cut? Today I will introduce a cutting equipment - AOYOO CNC EVA foam cutting machine.

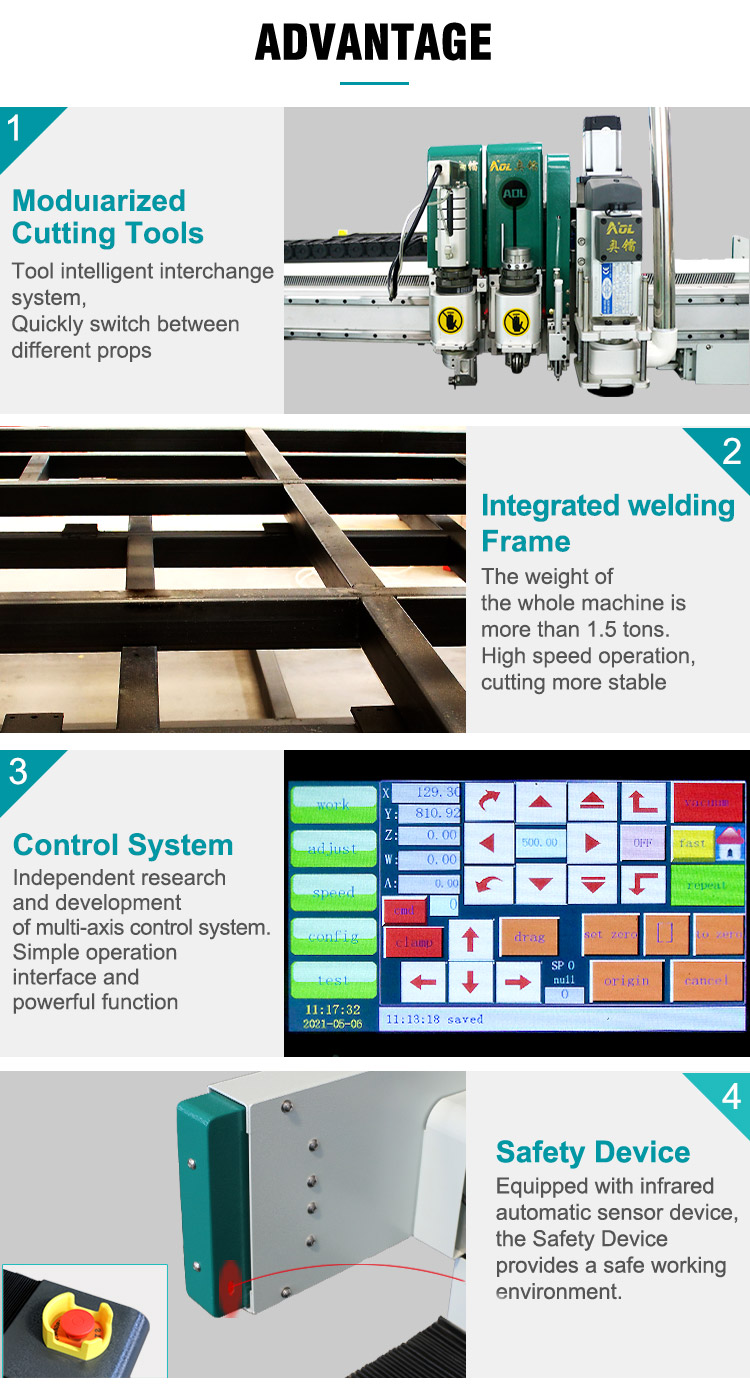

EVA foam vibrating knife cutting machine, the cutting thickness is about 1-10CM (depending on the material), cutting with a blade, no need to manufacture a large number of molds, and there will be no bevel problem during the cutting process, and there is no debris in cutting. Small hole-shaped products can be punched and cut with a punching knife, and the entire cutting process is environmentally friendly and pollution-free.

Effectively solve the three major problems encountered in the cutting process: "beveled edges are easy to appear in the punching process", "scraps are easily generated in the punching process" and "hole-shaped products are difficult to punch and shear".

At the same time, the whole machine bed of Aolai EVA foam vibrating knife cutting machine is equipped with a safety protection system, which can avoid some accidental injuries during the punching and shearing process of the punching machine. It is worth mentioning that an EVA foam cutting machine replaces 4-6 laborers, which greatly improves the cutting efficiency. With the addition of super nesting software, it can save more than 15% of materials, and truly make EVA manufacturers produce products efficiently. Double satisfaction with quality clearance.

AOYOO has been committed to the production and optimization of CNC cutting machines. We have an independent factory, which can completely realize the design, production, sales, delivery and after-sales service processes. AOYOO CNC EVA foam cutting machine is fast and easy to operate. It perfectly realizes the cutting shape you want. The whole process is automated without manual intervention. It adopts high-efficiency and high-precision servo motors to realize intelligent cutting faster and more accurately. Perfect pre-sale and after-sale service, pre-sale plan for you according to the specific situation of your cutting material, one-to-one guidance after sale, to ensure that you can master the operation method as soon as possible.

1. The AOL after-sales service team has more than 20 engineers.

2. At least 3 engineers serving an agent/customer, all of them can speak English.

3. We support complete user manual, use video and photos.

4. We support remote assistance to help you install and use the software.

5. We support 24*7 online guidance and services.

6. Our machines are guaranteed for 3 years, except for felts, knives and blades, during this period, if there is any problem, we will replace them with new ones for free by DHL, and for knives, we will repair them for free within one year.

7. We promise to send out replacement parts within 24 hours.

8. We will set up a service group for you, including AOL sales staff, AOL engineers, AOL sales managers, AOL sales directors and you (or your staff), if you have any questions, we will reply within 1 minute.

9. Free upgrade of AOL software for life.

If you want to know more, please contact us and we will answer you as soon as possible!