ASSURANCE

Printed fabric refers to the material that prints the pattern on the material. This material needs to be cut along the edge of the pattern, so professional image recognition software is required, and the printed fabric cutting machine is a professional equipment for cutting this material.

The calico cutting machine has a self-developed edge-finding cutting system, matched with camera hardware for photo recognition, to achieve the purpose of cutting. It is simple and basically completed by the equipment itself, so it can replace 4-6 manual workers.

The equipment has two functions of printing pattern extraction and cutting and contour extraction and cutting. Among them, the printing pattern extraction and cutting is for printed fabrics. After extracting the outline, it is only necessary to find the edge and cut, while the outline extraction and cutting are mostly for cutting irregular leather materials. It is necessary to extract the outline of the material first, and then activate the intelligent typesetting function in the extracted outline to achieve the purpose of typesetting and cutting in irregular materials. This cutting method can save between 10-15% of materials compared to manual work.

The calico cutting machine adopts integrated welding technology, after 800° high temperature heat treatment, the whole machine runs stably for a long time without deformation, and the cutting precision is high. Select imported Japanese Panasonic servo motor, pulse positioning, positioning accuracy ± 0.01mm, running speed up to 2000mm/s, the efficiency is about 4-6 labor efficiency.

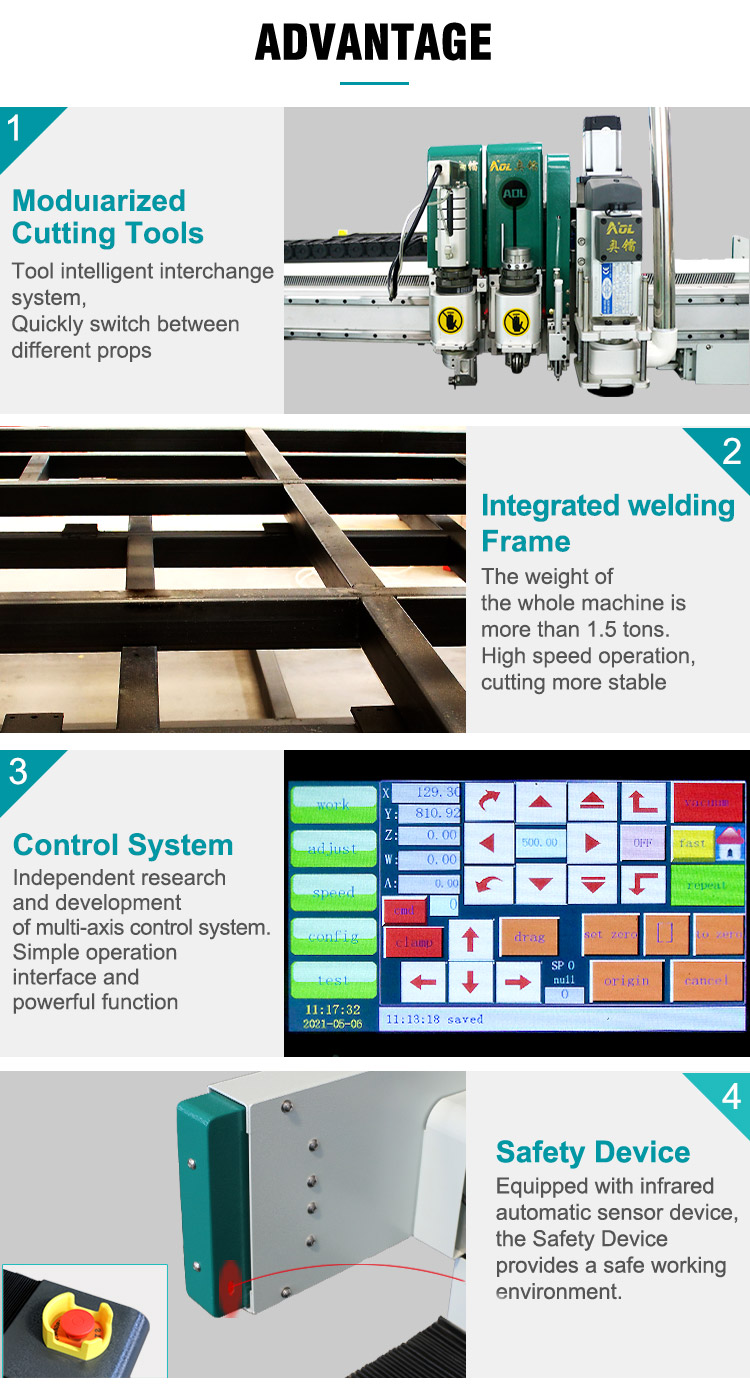

1. Independently develop and design CAM software, intelligent software compensates, optimizes the cutting path, and improves production energy efficiency.

2. Using high-quality linear guide, the accuracy error is ±0.1mm.

3. Japan's Panasonic servo system provides power, stable and continuous power supply.

4. The system intelligently optimizes typesetting and cutting, provides better cutting and filling paths, and saves more than 30% of materials.

5. The infrared induction safety device ensures the safety of the operator during the high-speed movement of the machine, and at the same time avoids the loss of cutting materials.

6. Aluminum-magnesium alloy adsorption platform, durable and not deformed.

7. The whole machine is dust-proof to reduce the equipment failure rate and prolong the service life of the equipment.

1. The AOYOO after-sales service team has more than 20 engineers.

2. At least 3 engineers serving an agent/customer, all of them can speak English.

3. We support complete user manual, use video and photos.

4. We support remote assistance to help you install and use the software.

5. We support 24*7 online guidance and services.

6. Our machines are guaranteed for 3 years, except for felts, knives and blades, during this period, if there is any problem, we will replace them with new ones for free by DHL, and for knives, we will repair them for free within one year.

7. We promise to send out replacement parts within 24 hours.

8. We will set up a service group for you, including AOL sales staff, AOL engineers, AOL sales managers, AOYOO sales directors and you (or your staff), if you have any questions, we will reply within 1 minute.

9. Free upgrade of AOYOO software for life.

If you want to know more about performance issues, please leave a message , we will have a professional staff contact you.