ASSURANCE

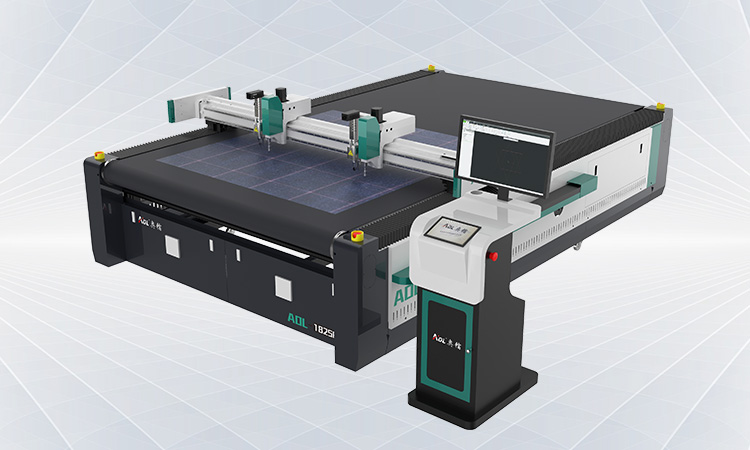

Vibrating knife cutting machine/cutting machine is a high-speed, single-layer (a small amount of multi-layer) material cutting equipment, which can automatically and accurately complete full cutting, marking and other processes, widely used in automotive interiors, advertising, clothing, home, composite materials and other fields; this cutting machine provides the best choice for automatic production in many industries with its precise, flexible and efficient characteristics.

Composite materials: The vibrating knife cutting machine replaces the traditional crafts such as hand-painting and hand-cutting in the production process of composite products, especially for complex samples such as special-shaped and irregular patterns, which greatly improves the production efficiency and cutting accuracy.

Composite materials: The vibrating knife cutting machine replaces the traditional crafts such as hand-painting and hand-cutting in the production process of composite products, especially for complex samples such as special-shaped and irregular patterns, which greatly improves the production efficiency and cutting accuracy.

Textile and clothing: Vibrating knife cutting machine is aimed at brand clothing. A total solution for the tailoring of haute couture garments.

Home textile: The vibrating knife cutting machine provides customized cutting integrated solutions according to the home textile industry, which can not only improve the utilization rate and processing efficiency of fabrics in the home industry during the cutting process, but also effectively improve product quality and achieve high efficiency, Comprehensive optimization of low consumables and high quality.

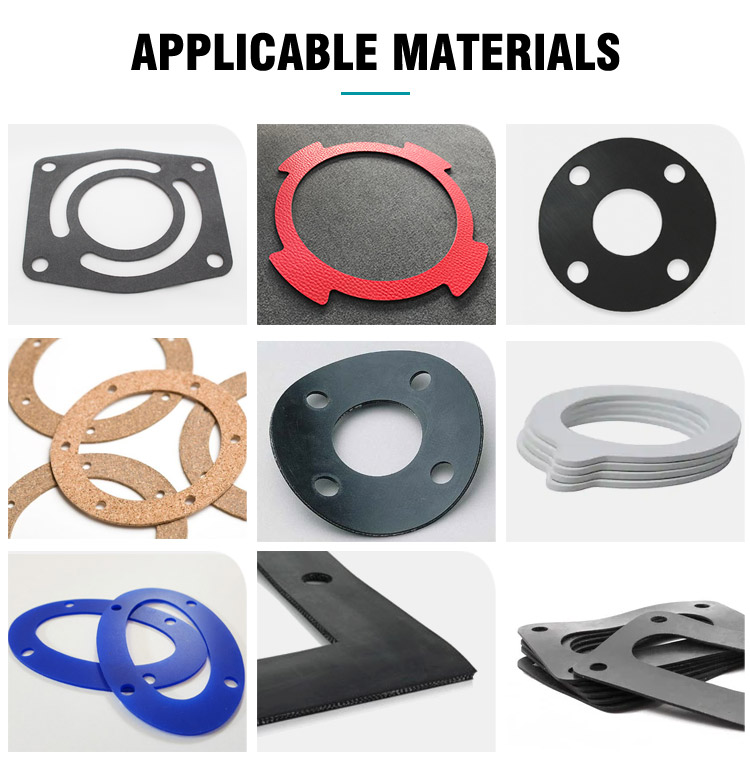

Sealing material: The air vibrating knife cutting machine is mainly used for cutting the sealing gasket made of non-metallic materials, and has won the praise of the industry with good technical standards and after-sales service; the air vibrating knife cutting machine is mainly used in hydraulic sealing , flange seal, rubber, plastic, ceramic, graphite, rubber-asbestos board, aerogel felt-polyurethane and other materials. Sealing products are molded by molding, and special seals need to be opened separately, which is costly, has long cycle times, and is not easy to control the accuracy. The birth of cutting and sealing equipment has solved the above problems. The pneumatic vibrating knife cutting machine can complete the cutting of high-quality sealing products of any cross section and any size, and the end user can pick up the goods at any time, saving time and cost of substitute processing. The products are widely used in hydraulic and pneumatic equipment with strict requirements on sealing effect, such as automobiles, mining brackets, and construction machinery.

Automotive interior: The vibrating knife cutting machine proposes a full-coverage cutting integrated solution for different cutting requirements and different cutting materials in the automotive interior industry. The cutting products include full-enclosed mats, large-enclosed mats, wire loop Flexible materials such as floor mats, car seat covers, etc.

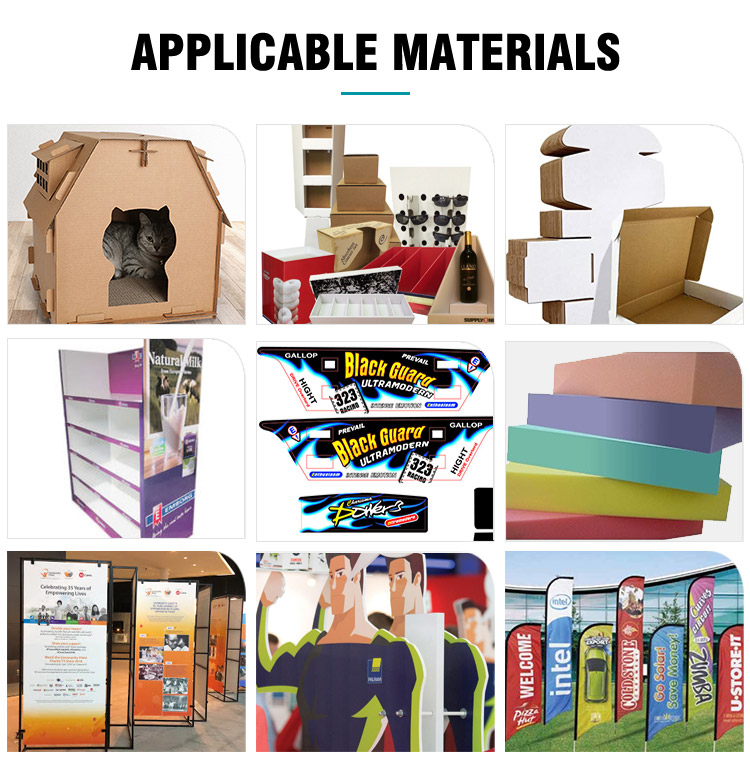

Advertising packaging: CNC vibrating knife cutting machine provides a complete solution for the advertising industry, especially suitable for the processing of PP paper, KT board, Chevron board, self-adhesive, corrugated paper, honeycomb paper and other materials, and can be configured with high-speed milling The knife is processed for hard materials such as acrylic and aluminum-plastic panels. After adding an automatic feeding module, automatic full-time production can be carried out.

Other industries: The vibrating knife cutting machine has a wide range of applications in the global non-metal industry, such as footwear, luggage, inflatables, sporting goods, toys, wind power, medical supplies, etc., providing professional and reliable cutting for users in the global non-metal industry. All-in-one solution.

Computer graphics, through internal data processing, and then transmitted to the machine control card, the control card then sends command pulse signals to the servo drive, the drive drives the servo motor to move to achieve the movement of the machine, it will vibrate up and down when cutting, tens of thousands of times per minute Vibration, similar to the principle of a saw blade, but without sawtooth, no powder is generated, and a signal is sent to the cutting tool to cut the raw material. The vibrating knife can freely replace the cutter head. According to different materials, you can choose round knife, half cutter, drag cutter, bevel cutter, milling cutter and so on.