ASSURANCE

"Machine substitution" is not simply to replace human with machine. The essence is technological innovation, process innovation and management innovation with equipment renewal as the carrier; the core is to replace old equipment with advanced technical equipment to improve labor productivity; the purpose is to speed up the change of the growth mode that relies too much on low-cost labor and greatly reduce the employment of enterprises. , and become the source of power for new industrial optimization and upgrading and continuous economic growth. The replacement of people by machines is the general trend of the current manufacturing industry, and it is also an inevitable trend of enterprise transformation and upgrading.

1. Quality: The use of machine production greatly reduces the waste of materials, the quality is stable, and the product qualification rate is improved. Quality and efficiency are the two lifelines of an enterprise.

2. Employment: In enterprise management, from managing people to managing machines, it saves a lot of trouble and greatly reduces costs, especially in the current situation of difficult recruitment. It not only solves the problems of shortage of skilled workers and rising labor costs, but also improves labor productivity, and can achieve multiplier effects with half the effort.

3. Innovation: "Machine substitution" enterprises can not only accelerate the good atmosphere of modern technological innovation, stimulate the potential and vitality of independent innovation of small and medium-sized technology enterprises, but also promote the transformation and upgrading of labor-intensive enterprises.

1. The latest version of clothing CAD: automatic patterning, modification of related patterns, automatic nesting, etc. These can improve the speed and efficiency of clothing patterning, and it is more economical than manual and early intelligent nesting. rate as high as 15%.

2. Automatic spreading machine: It can improve the spreading efficiency. Nowadays, the fabrics of many high-end products are thin and elastic knitted fabrics. This type of spreading is difficult, requires a lot of labor, and there are many uncertain factors. Using one spreader saves 4 people.

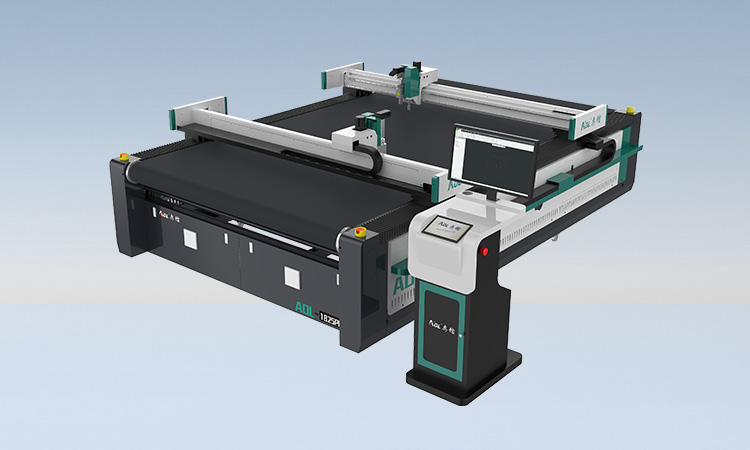

3. Automatic vibrating knife cutting machine: It can improve the cutting efficiency, 10 people by hand, 2 people can use the machine, save 8 people (and underwear and swimsuit factories can achieve an amazing saving of 12-15 people); can improve sewing efficiency 5-10%, the pieces cut by the automatic cutting machine are more accurate, and the efficiency is improved during sewing.