ASSURANCE

Bubble film is a product made of high-pressure polyethylene as the main raw material, adding whitening agent, opening agent and other auxiliary materials, and extruding and blistering into bubbles at a high temperature of about 230 degrees. It is a new type of plastic packaging material with light texture, good transparency, non-toxic and odorless, which can play the role of moisture-proof, buffering and heat preservation for products. Also called a bubble pad. Widely used in electronics, instrumentation, ceramics, handicrafts, household appliances, bicycle shops, kitchens, furniture and paint products, glass products and precision instruments and other shock-resistant buffer packaging. It can be made into bubble bags, bubble kraft paper envelope bags, car sun shields, thermal insulation cushions, thermal insulation materials, etc.

The market demand for this type of material is very large. Before mechanization, all the steps were made by hand. Nowadays, it is very difficult to find high-tech manual workers, and the wages are very high. In addition, there is another disadvantage of manual cutting. It is a waste of raw materials, I believe many people are aware of this.

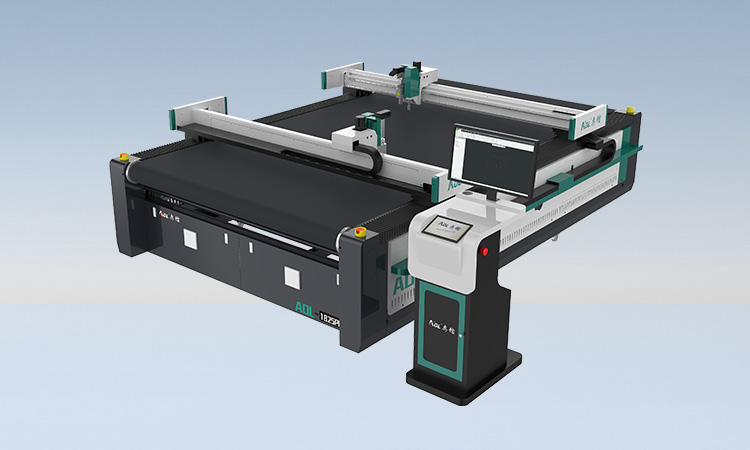

Knowing that the era of automatic cutting is coming, it has helped many enterprises to solve many problems. AOL Bubble Film Cutting Machine has been committed to providing efficient cutting solutions for the bubble film manufacturing industry for many years. The bubble film vibrating knife cutting machine developed and produced adopts the vibrating knife cutting technology, which is specially designed for the bubble film packaging industry and can meet the mass production needs of packaging enterprises. Let's take a look at the characteristics of AOL CNC vibrating knife cutting machine.

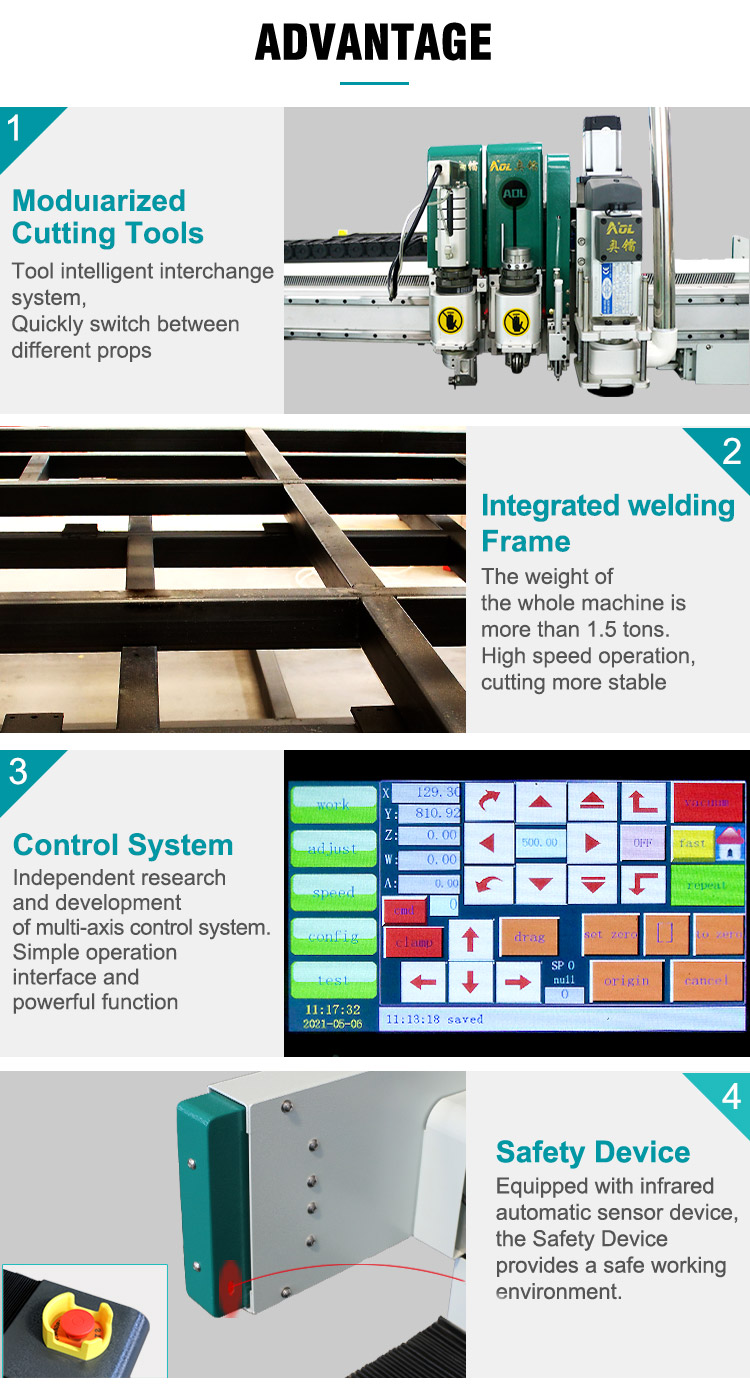

1. Table compensation function: The flatness of the table is detected by a high-precision distance detector, and the plane is corrected in real time through the software to achieve a perfect cutting effect.

2. Overcut optimization: The self-developed CAM software is used to systematically optimize the physical overcut phenomenon of the tool, restore the graphic outline to the greatest extent, and bring customers the perfect cutting effect

3. Vacuum adsorption function: super strong wind, strong suction, the size of the vacuum adsorption area can be selected, and the power consumption can be greatly reduced

4. High-definition CCD camera: High-definition CCD camera realizes automatic positioning and sleeve cutting of various materials, eliminating the problems of inaccurate manual positioning and printing deformation.

5. Positive and negative nesting: Combined with the boundary recognition function, quickly identify and locate the material boundary, and realize the positive and negative graphics nesting

The overall weight of the bubble film cutting machine is more than 1.5 tons, and the high-speed operation does not vibrate. And our equipment will go through 72 hours of uninterrupted high-load proofing and trial cutting before leaving the factory.

AOL fully automatic computerized cutting system is specially designed for your mass production cutting needs, using a blade cutter for cutting, AOL fully automatic cutting machine provides precise results when told to run, easily producing a range of lines, shapes and arcs.

Email:info@aolcnc.com

phone:0086-18560162709

WhatsApp/Wechat:0086-18560162709

YouTube:https://www.youtube.com/channel/UCctbMXFvompG-41Wecb1mpw

website:https://www.aoyoocut.com/

Facebook:https://www.facebook.com/AOYOOCUTTER