ASSURANCE

Under the trend of the global environment, many industries have been greatly impacted, especially traditional factories mainly based on manual production. Due to the pandemic, a large number of orders have been cancelled, and the business has been seriously affected. Tens of thousands of factories have shut down, had to lay off workers, or simply closed.

It has to be said that this epidemic has sounded the alarm for traditional manufacturing industry. Under the background of the intelligent era, it is unrealistic to blindly rely on a large number of employees to achieve stable growth of performance and achieve stable anti-risk ability.

Based on the leather processing factories with maximum manual operation, the common leather and leather cutting and processing problems can be divided into the following seven points, excluding the impact of the epidemic environment:

1. Manual plate drawing and plate making technology is complicated, which can not effectively meet the requirements of small batch customization

2. Manual discharge, low utilization rate of raw materials, increase product cost

3. Manual cutting process has high requirements, non-standard cutting, and low efficiency

4. There are many kinds of leather materials and cut pieces, which are difficult to manage manually

5. There are so many defects in the genuine leather that manual identification efficiency is too low

6. Diversified typesetting needs, complicated cutting, punching and marking processes for genuine leather

7. It is difficult to find senior cutting workers and the labor cost is high

Therefore, in the face of the large market environment, how to achieve faster and better leather cutting processing, to maximize the production of products, leather processing manufacturers are facing the top priority.

To solve the problems that cannot be solved manually, it is necessary to use intelligent equipment, adopt data intelligent operation, and crack the industry problems one by one.

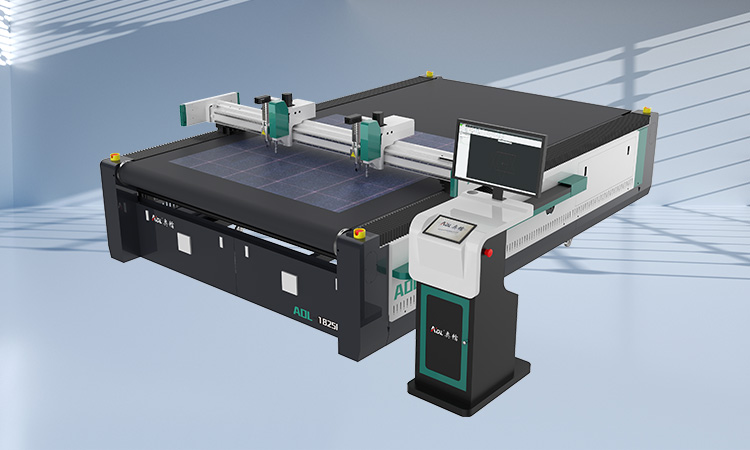

Also take leather cutting as an example, "manual cutting quality is low, recruitment is difficult" and other problems, can take special intelligent cutting equipment to solve. But in the purchase of equipment, also need to pay attention to a few points.

1. Support automatic typesetting of materials to maximize the problem of material waste

Choose equipment with super discharge system, this system can use computer intelligence to optimize the layout path, directly omit manual typesetting, maximize can save more than 15% of the material.

Saving material means saving money. For example, if we spend 1 million yuan a year on materials, we can save 10% and reduce the cost, which will improve the competitiveness of products.

2. Support computer import version to solve the problem of small batch customization

Support direct import version of the equipment, can directly import the layout into the computer end, say goodbye to many manual board, drawing board, is conducive to make cutting faster and simpler.

Of course, at the same time can save the cost of plate, reduce the cost of products.

3. Support contour recognition, farewell to the long artificial dermal identification step

In the face of leather cutting, the most difficult problem is to avoid small defects. Therefore, if you support the camera visual recognition system, you can directly use the computer for dermal contour, defect identification, high precision, zero error, enhance the competitiveness of products.

4. Automatic operation of the whole machine to maximize the output of the factory

This is the main purpose, to solve most of the manual problems. Compared with the manual, the machine can work continuously for 24 hours to maximize the production.

At the same time, when the business gradually picks up, we can directly solve the problem of recruitment difficulties. After all, one machine can replace three to five cutters.

The future is an intelligent era. In the process of continuous progress of the factory, the staff is also improving, and it will be better managed.

In general, simple manual operation will greatly affect and inhibit the development of enterprises, resulting in a large amount of enterprise resource waste, cost expenditure, and seriously affect the product market.

For more information, please consult:

Email: info@aolcnc.com

Phone: +86-0531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://www.aoyoocut.com/