ASSURANCE

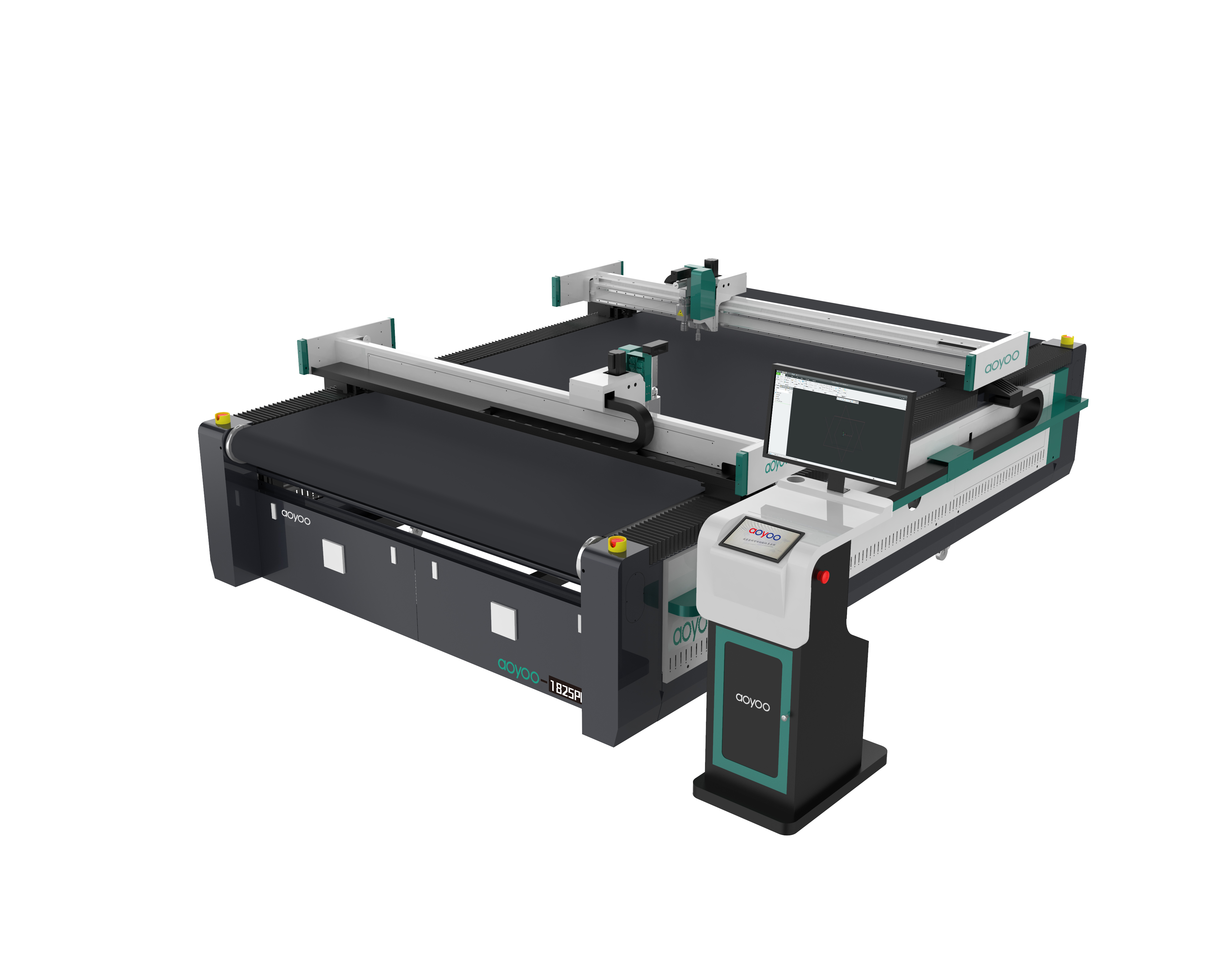

With the use of more and more carton materials, paper packaging cutting machines are growing of widely used in carton cutting. In traditional paper packaging cutting, we only need to know the customer's cutting thickness and size, and provide him with a machine that can be cut. , But the current customers are not only asking for cutting as simple as they are. They manage to improve their management by rearranging the process flow, reducing the back-end labor, improving efficiency, and bursting out instant output.

Therefore, we need to provide customers with more cutting solutions and equip them with different tools and equipment according to their various requirements

Such as: the use of UV equipment and AOYOO CNC cutting equipment, so that innovative design and production have greater development space.

AOYOO digital numerical control cutting system, supporting camera positioning, can achieve precise cutting regardless of the plate or coil, with high efficiency. Especially for the cutting of special-shaped graphics, the quality is higher than manual cutting, and the efficiency is increased by more than 4 times; the cutting efficiency of regular graphics is about 2 times higher than that of manual cutting. If you want to learn more paper packaging CNC cutting machine types or are interested in knowing how to choose a CNC cutting machine, please continue reading.

Among all packaging types, paper packaging is one of the main categories, and the output value accounts for about one-third of the overall output value of the packaging industry. The scope of application involves all aspects of life. Mainly used in the packaging of fragile products such as food, electrical appliances, beverages, glass, ceramic products and cans. Due to the different types of packaging and the density and shape of the cutting materials, different types of cutting equipment need to be selected. In addition, the paper packaging cutting machine can also be used in leather, advertising packaging, carpet industry, textile industry, composite material cutting, and automotive interiors. It is suitable for the processing and cutting of various flexible materials.

Advantage:

1. Wide sources of raw materials, low prices, simple economy and high production flexibility

2. Good protection performance, high hygiene and safety

3. Convenient to manufacture and decorate, lighter in weight

4. Waste can be recycled, no white pollution

5. Convenient storage and transportation

Shortcoming:

1. Poor waterproof performance

2. Easy to be pierced by sharp objects, poor toughness

3. There are certain restrictions on weight bearing

According to the material classification, it can be divided into cardboard, Paper jam, packaging paper, corrugated paper, and honeycomb cardboard.

Cardboard, also known as board paper, is a thick sheet of paper made of various pulps and interwoven fibers. The difference between cardboard and paper is usually distinguished by basis weight and thickness. Usually, the basis weight exceeds 225g/㎡ and the thickness is greater than 0.5mm as cardboard. Individual basis weight less than 225g/㎡ is considered paper; paper with thickness greater than 0.1mm is called cardboard. Packaging cardboard, such as box cardboard, kraft cardboard, yellow cardboard, white cardboard, and impregnated liner cardboard.

Paper jam is roughly divided into three types, white cardboard, white-bottomed whiteboard and gray-bottomed whiteboard. White-bottomed whiteboard paper and gray-bottomed whiteboard paper are also collectively referred to as board paper. The difference between white cardboard and paperboard is that: white cardboard is made from pure pulp; board paper is made from waste paper pulp. The original pulp means that the material is taken directly from the forest. This kind of pulp is because The fiber is not damaged, so the paperboard made out of paper is very strong, and the technical indicators are relatively good. Board paper is made from waste paper pulp. The paper made from this kind of pulp does not have good physical properties, so it cannot meet the requirements of very high-end packaging and printing. At the same time, because it contains waste pulp, it cannot directly contact food, so its use is limited.

Paper jam has a wide range of uses, most of which are used in color box packaging, packaging paper bags, creative samples, business card printing, certificates, invitations, covers, monthly desk calendars, and postal postcards.

There are many types of jams, so when choosing a die cutting machine, choose different cutting equipment for different purposes. For jams with inkjet patterns and Mark points, you need to choose a small camera; ordinary jams are recommended to use a vibrating knife and a knife. And the pressure wheel.

Packaging paper can be divided into ordinary packaging paper, special packaging paper, label paper, oil-proof packaging paper and moisture-proof packaging paper, etc. Ordinary packaging paper is usually stronger and can be used in general packaging; special packaging paper is made according to the purpose of the product Choice, different products choose different special packaging paper; trademark packaging paper is used as packaging after printing. Various types of packaging paper have different properties and uses.

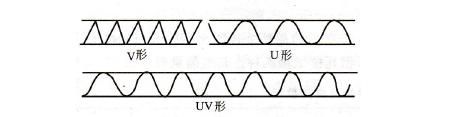

Corrugated paper is made of corrugated paper processed into corrugated paper from face paper, lining paper, and core paper. According to different needs, corrugated paper can be divided into single corrugated paper, double corrugated paper, and three-layer corrugated paper. Single-layer corrugated paper is generally used in commodities. The inner protective layer of the package is either a lightweight card grid or a pad to protect the product from vibration or collision during transportation. Three-layer and five-layer corrugated paper are the most commonly used in our daily life. Many products are used in packaging. Three or five layers of corrugated cardboard for simple packaging. The shape of corrugated board can be divided into V shape, U shape and UV shape.

The characteristics of the V-shaped corrugated wave are: the plane is resistant to pressure, it can save the amount of adhesive and corrugated paper in use, but it also has certain shortcomings. This kind of corrugated board has poor cushioning properties. Easy to recover.

U-shaped corrugated waves are characterized by large glue area, firm adhesion, and a certain degree of elasticity. When subjected to external shocks, it is not as fragile as the V-shaped corrugated wave, but the strength of the plane against pressure is not as good as that of the V-shaped corrugated.

Therefore, when cutting corrugated paper, it is recommended to use AOYOO 1625 non-feeding vibrating knife, optional tool double knife seat pressure wheel, marking pen.

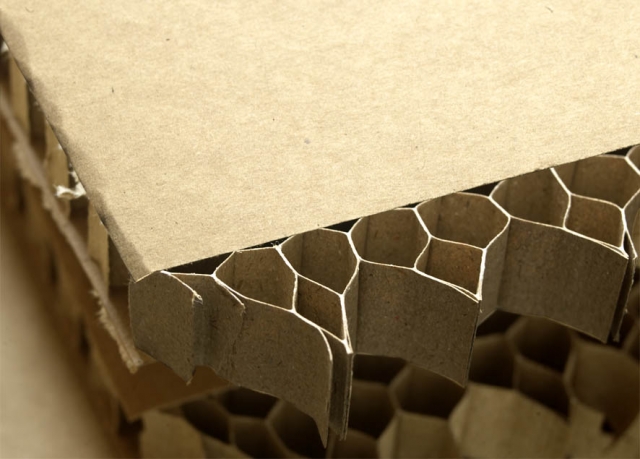

Honeycomb paperboard is made according to the principle of the honeycomb structure. The corrugated paper is glued together to form countless hollow and three-dimensional hexagons to form an overall stress member. This material is relatively light, inexpensive, and has high strength. , The recyclability is relatively high, so it is well received by the market in developed countries and regions such as the Netherlands, the United States, and Japan. The machine type we recommend for this kind of material is AOYOO 1625 non-feeding vibrating knife (pneumatic knife for thickness greater than 30mm), Vcut, and marking pen (for a few).

1. Cutting accuracy and cutting speed are better than traditional cutting

2. Reduce labor cost, good cutting effect, no pollution

3. Simple operation and high safety

4. It can realize the cutting of complex style carton with high efficiency

5. High-power servo motor can work for a long time

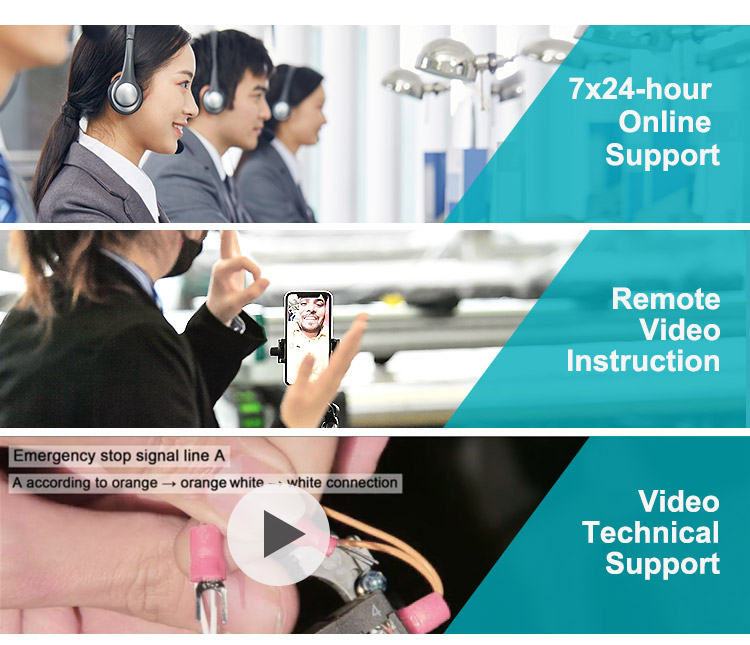

AOYOO has been committed to the production and optimization of CNC cutting machines. We have an independent factory that can complete the design, production, sales, delivery and after-sales service processes. The AOYOO paper packaging cutting machine is fast, simple to operate, and perfectly realizes the cutting shape you want. The whole process is automated without manual intervention. It uses high-efficiency and high-precision servo motors to achieve smart cutting faster and more accurately. Perfect pre-sales and after-sales service, pre-sales plan for you according to the specific situation of your cutting materials, and after-sales one-to-one guidance to ensure that you can master the operation method as soon as possible.

End:

End:I believe you have a good understanding of the AOYOO paper packaging carton cutting machine through the above introduction. If you want to better cut more refined products, please do not hesitate to choose us. While providing cutting machine products and customized services, we pay more attention to providing you with the best cutting solutions, and everything only creates greater value for you. I guarantee that the AOYOO CNC cutting machine sold can meet all your needs. And we can introduce you all the contents of the machine in detail. Looking forward to your news!

If you want to know more about performance issues, please leave a message , we will have a professional staff contact you.

E-mail:info@aolcnc.com

phone:+86-18560162709

WhatsApp /微信:+8618560162709

youtube:https://www.youtube.com/channel/UCctbMXFvompG-41Wecb1mpw

website:https://www.aoyoocut.com/

Facebook:https://www.facebook.com/AOYOOCUTTER