ASSURANCE

Different users have different processing requirements, and different types of cutting machines also have different disassembly and installation steps. This article will introduce how we disassemble the Aolai 2125 carpet rack welding CNC cutting machine. The customer receives it and installs it in reverse according to the disassembly steps. Just use it. If you want to know the answer or are interested in learning how to assemble CNC machine tools, please continue reading.

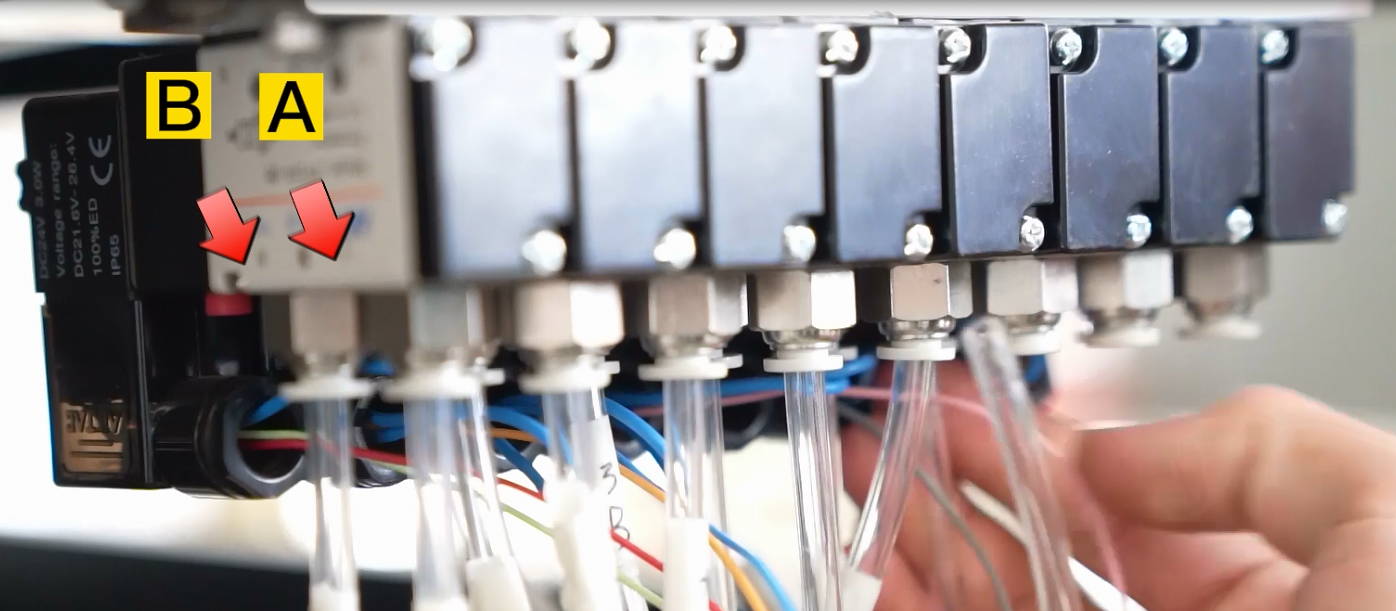

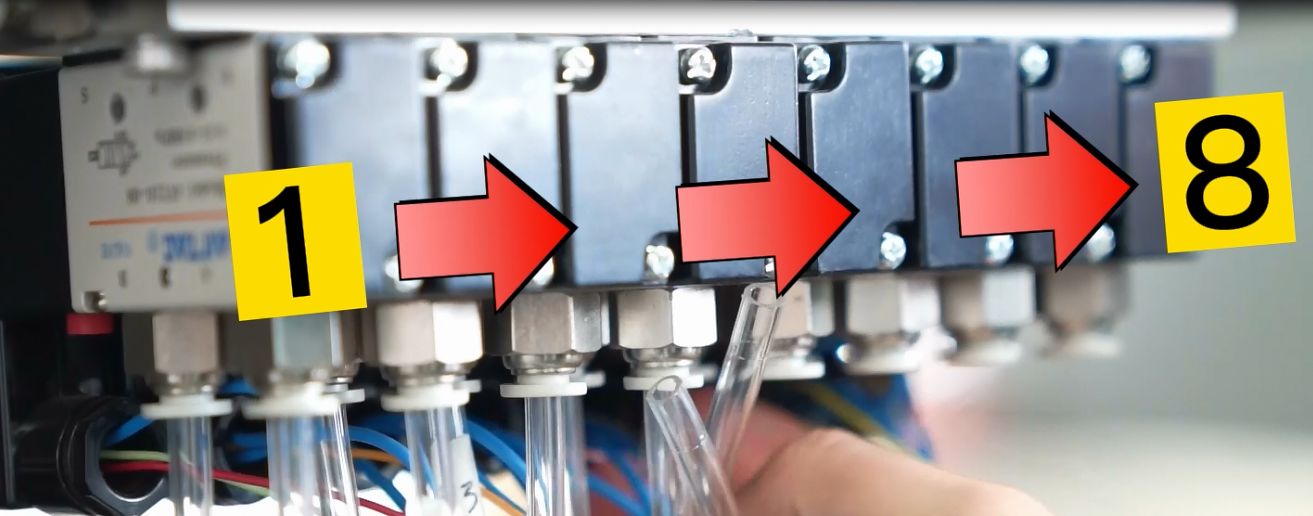

1. There are two air pipes AB on each solenoid valve. We will mark each air pipe with A1, A2...similar to this. The outer row is A and the inner row belongs to B. After (from left to right) sorted according to 1-8

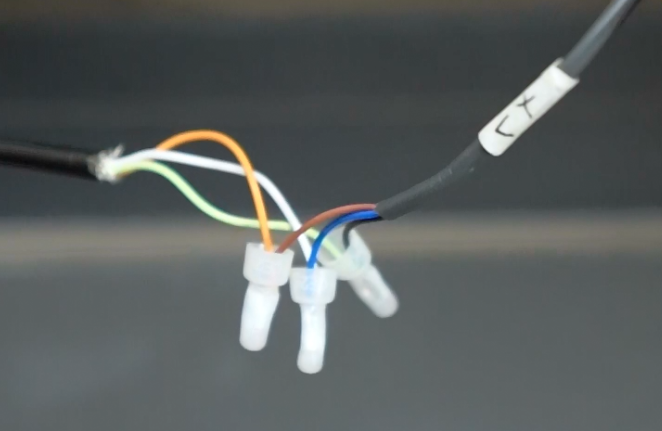

2. Remove the intake air pipe of the solenoid valve, this air pipe will be marked as Z

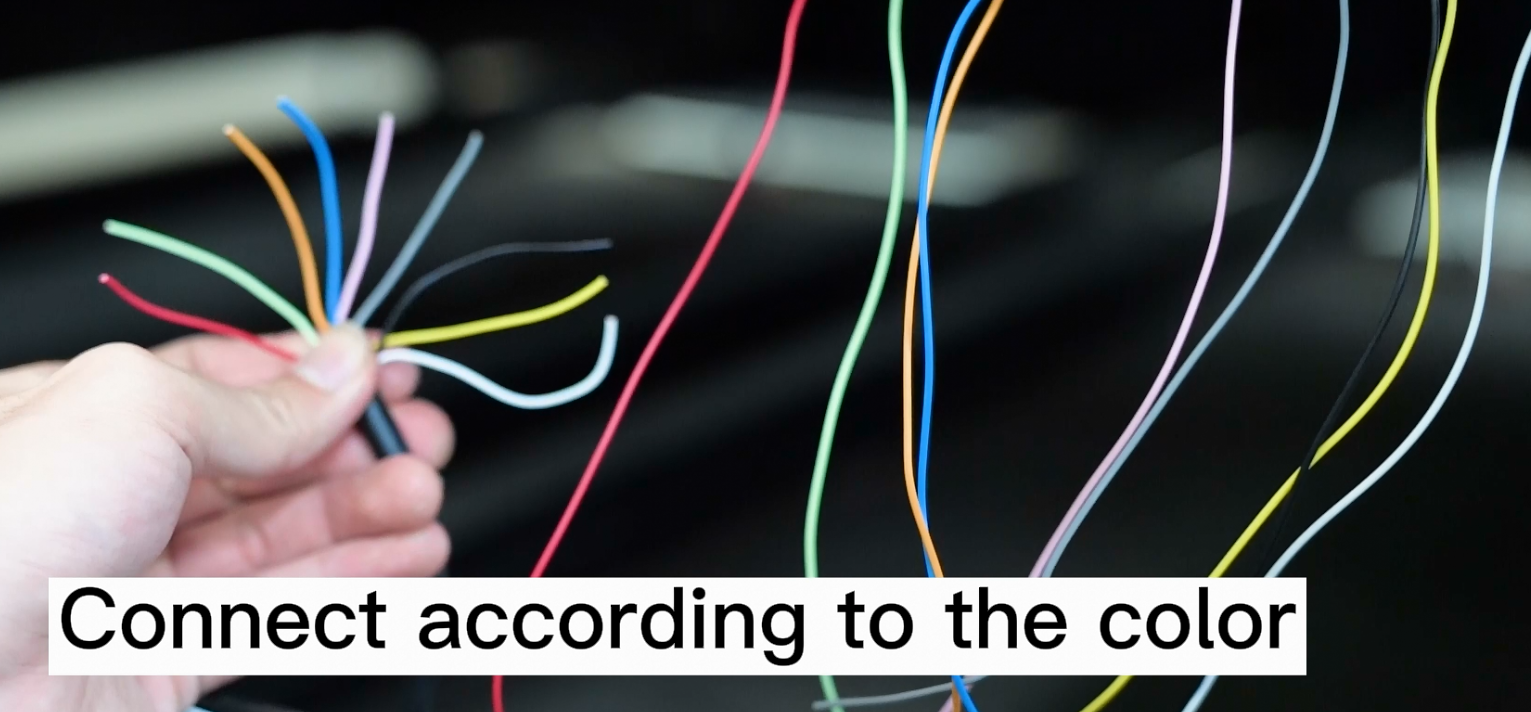

3. Remove the signal wire of the solenoid valve. There are nine colors of red, green, orange, blue, pink, gray, black, yellow, and white. We will cut it from the middle to facilitate the separation of the front and back of the machine. The colors meet)

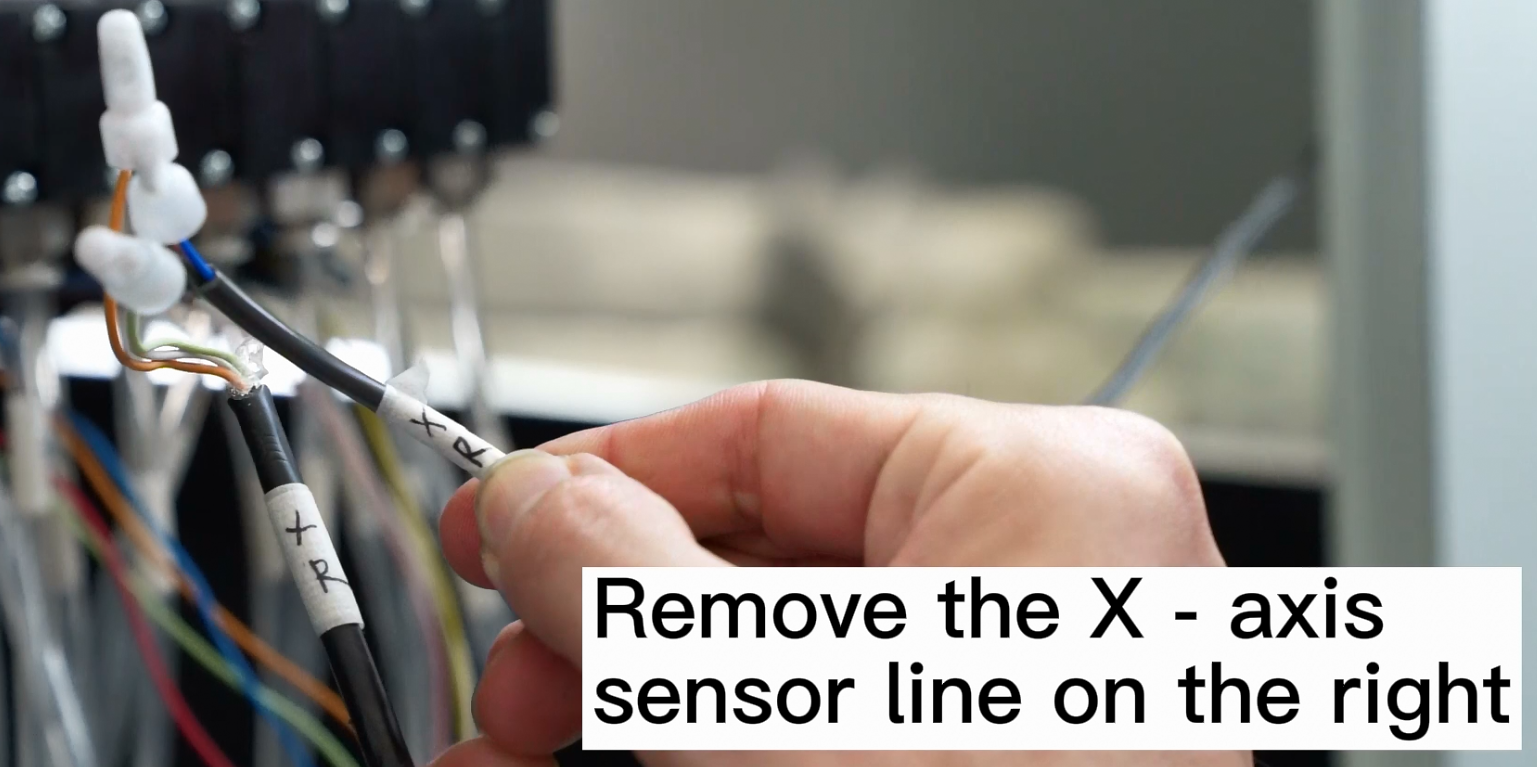

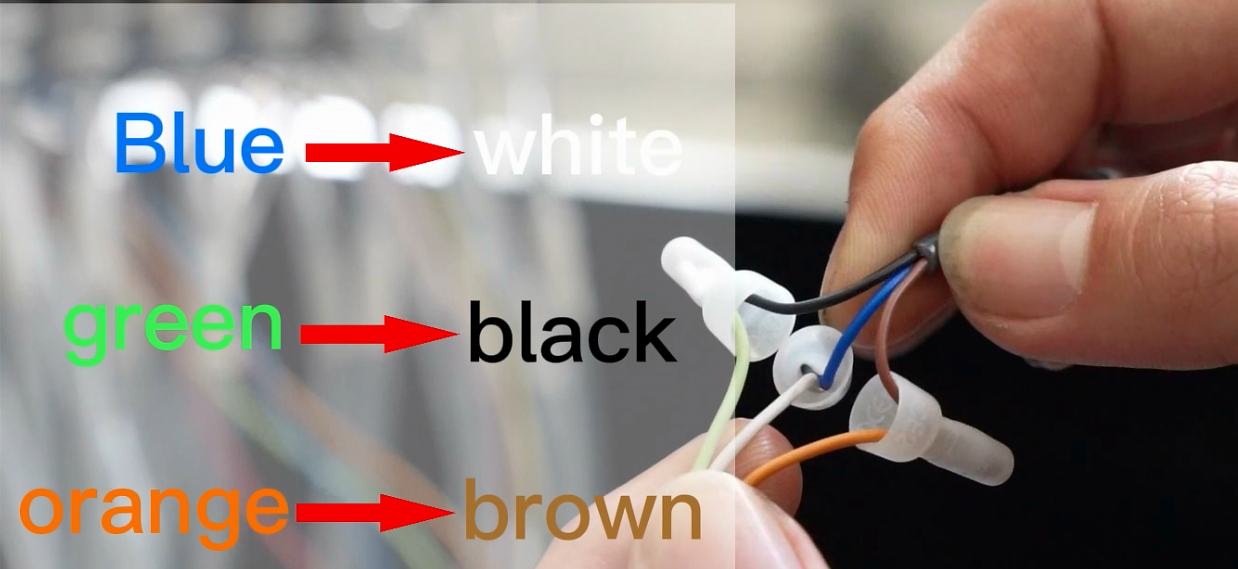

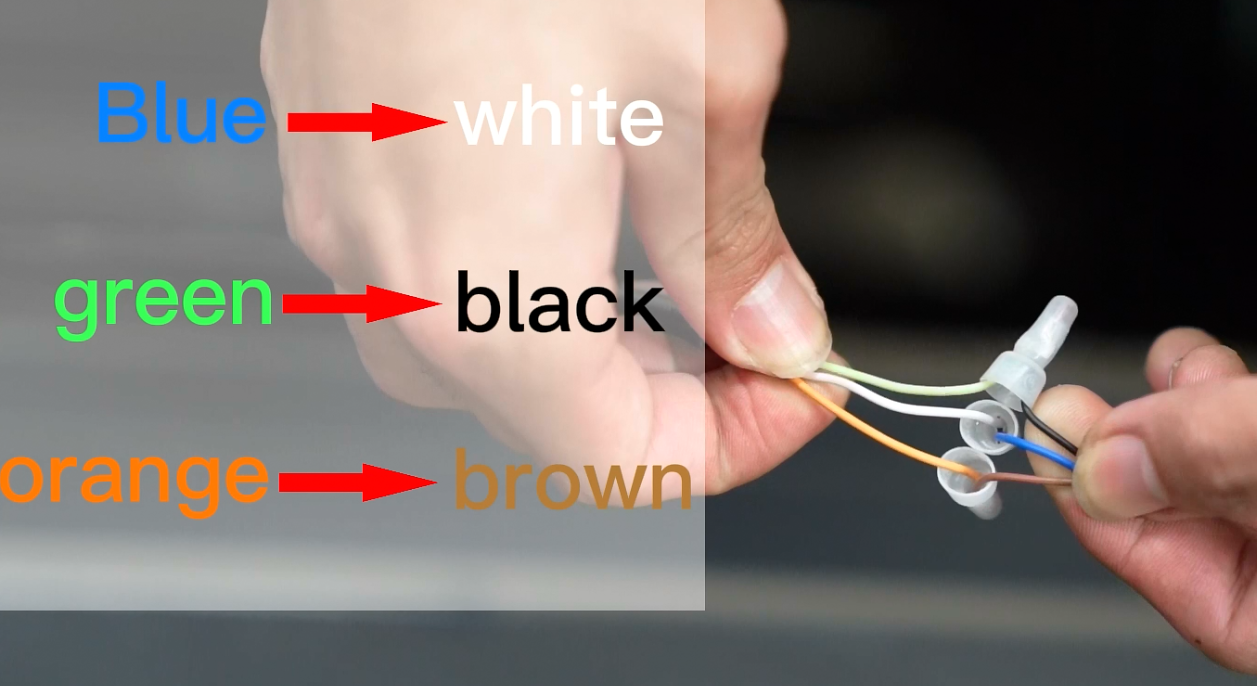

4. Remove the limit line on the right side of the X axis and mark it as XR. The corresponding wiring colors are blue to white, green to black, and orange to brown.

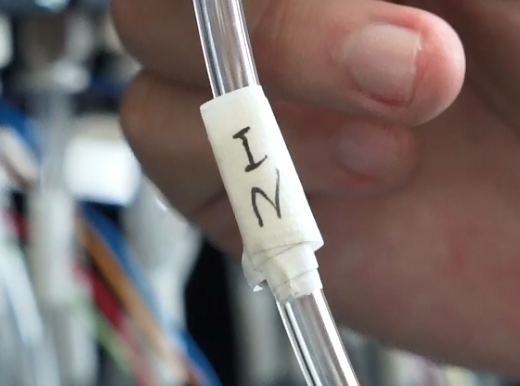

5. Remove the total air intake of the machine, the air pipe at this position is marked as IN

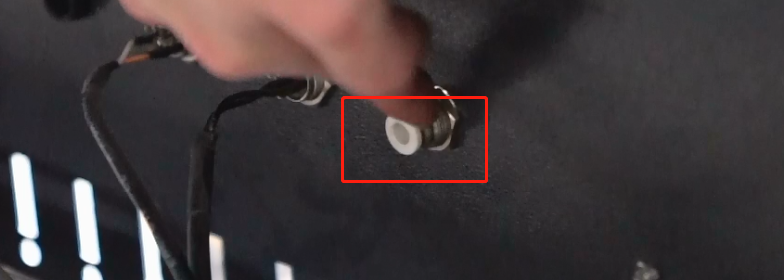

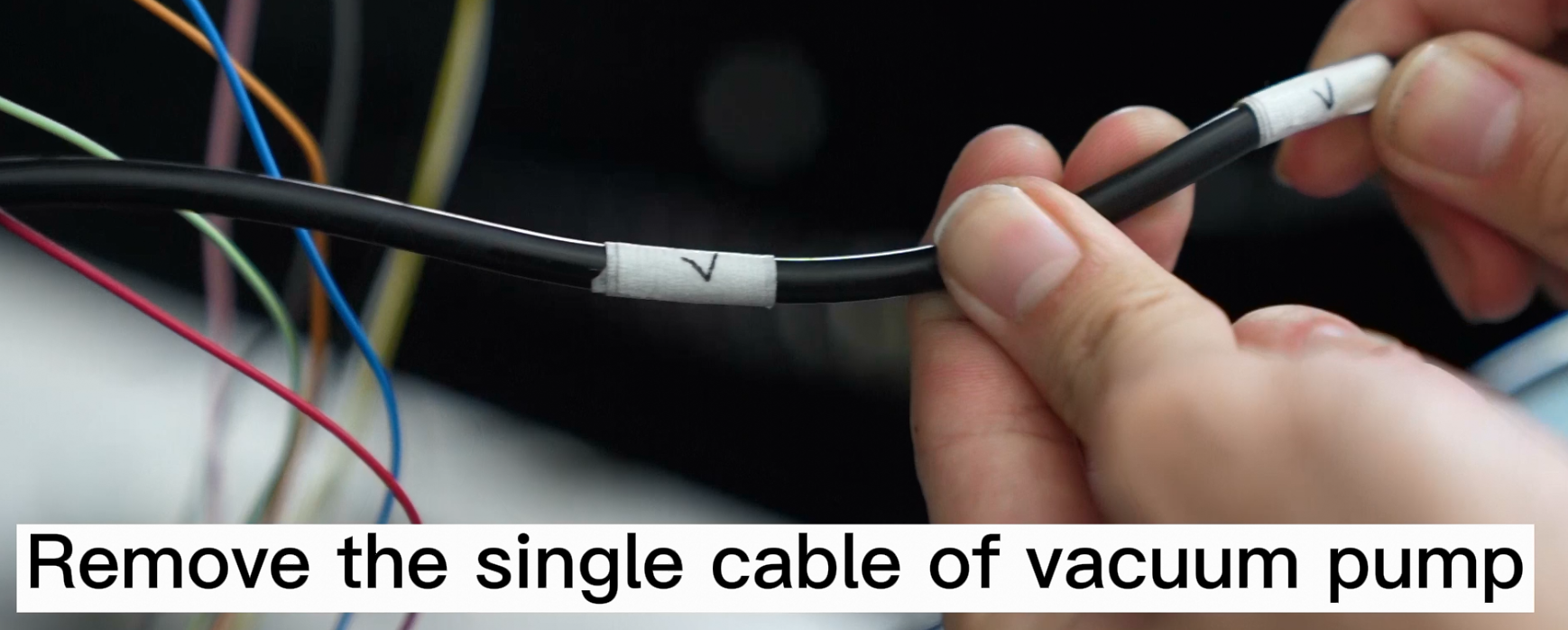

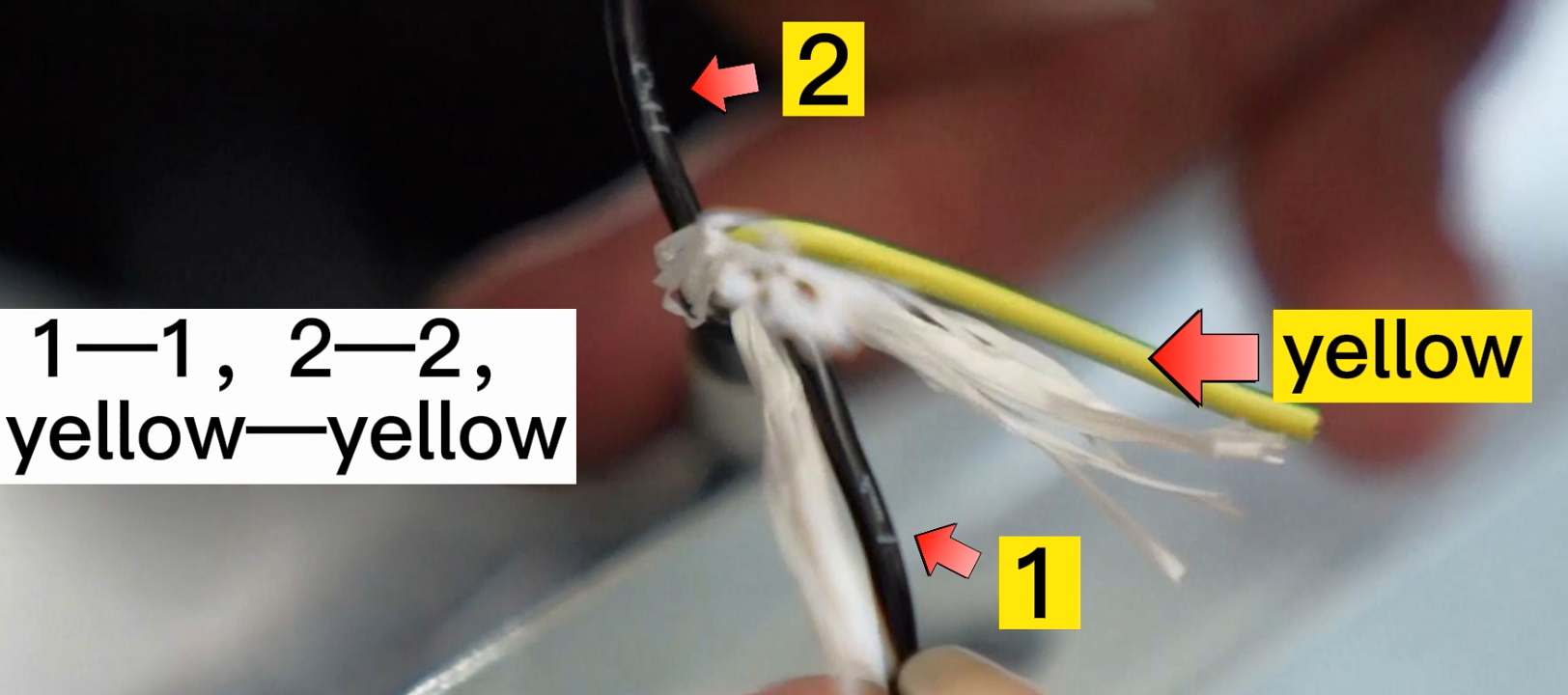

6. Remove the signal wire of the fan, which is marked as V here (when receiving the goods, follow the order of black one to black one, black two to black two, and yellow to yellow)

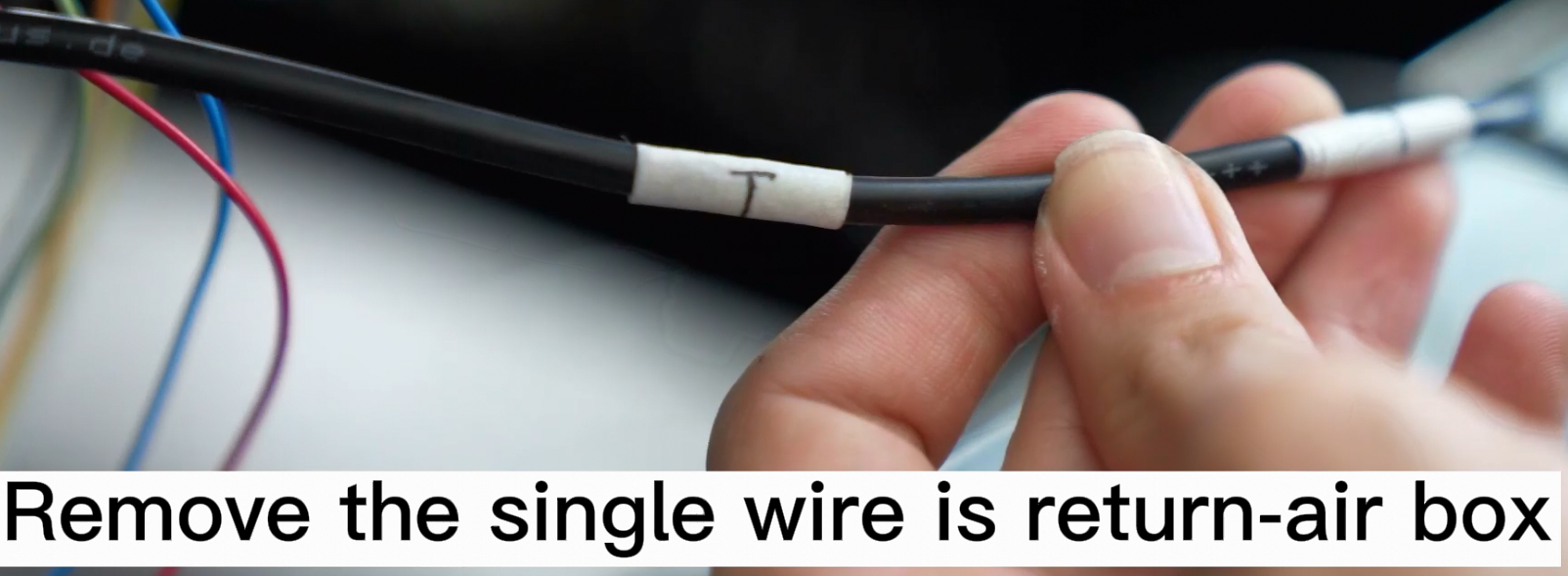

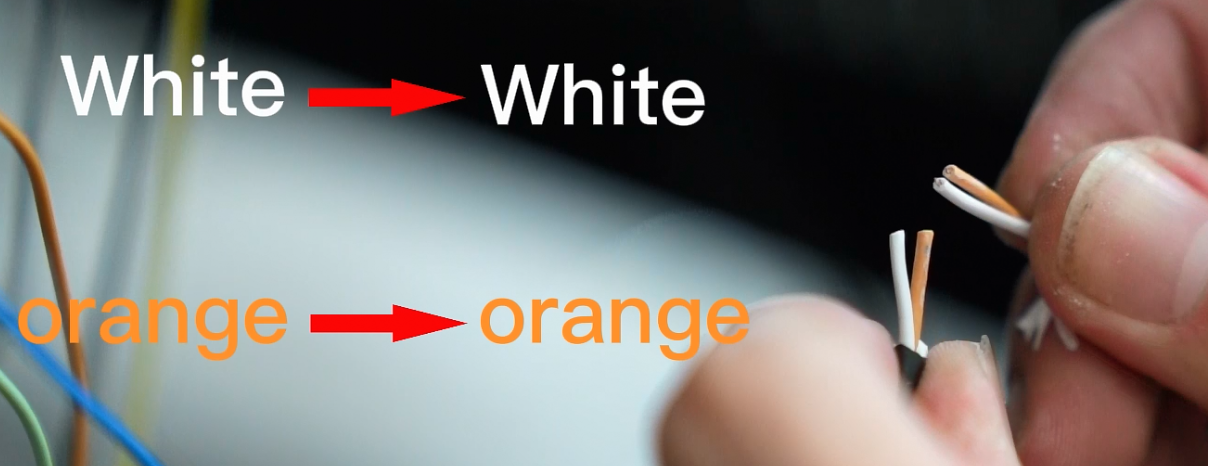

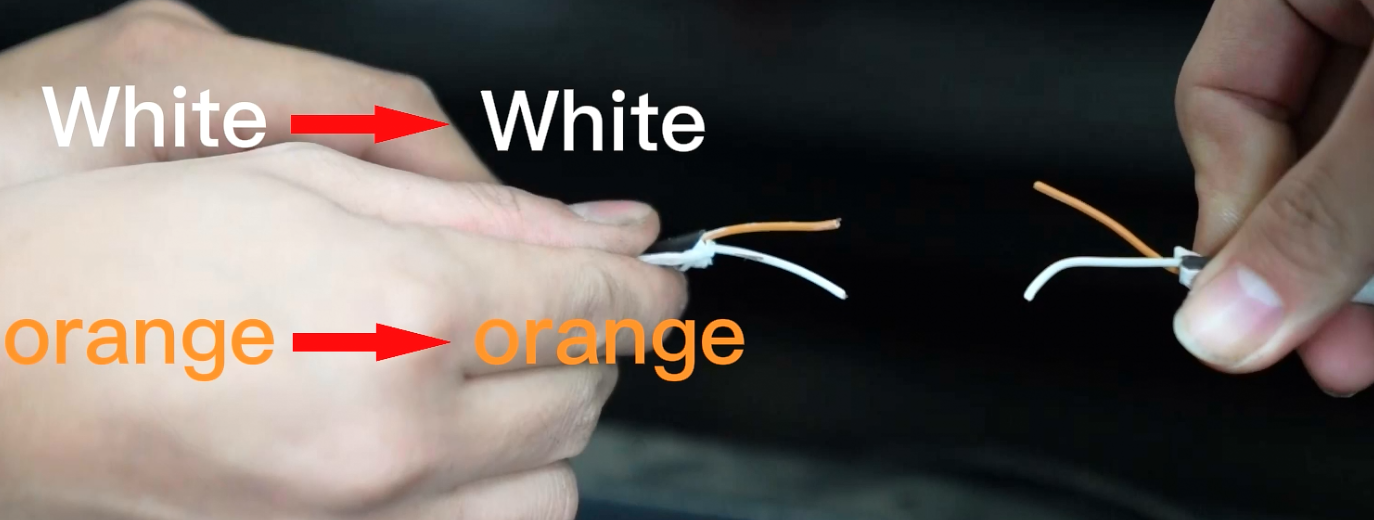

7. Remove the signal wire of the return air box, which is marked as T here (the received goods shall be connected in accordance with white to white and orange to orange)

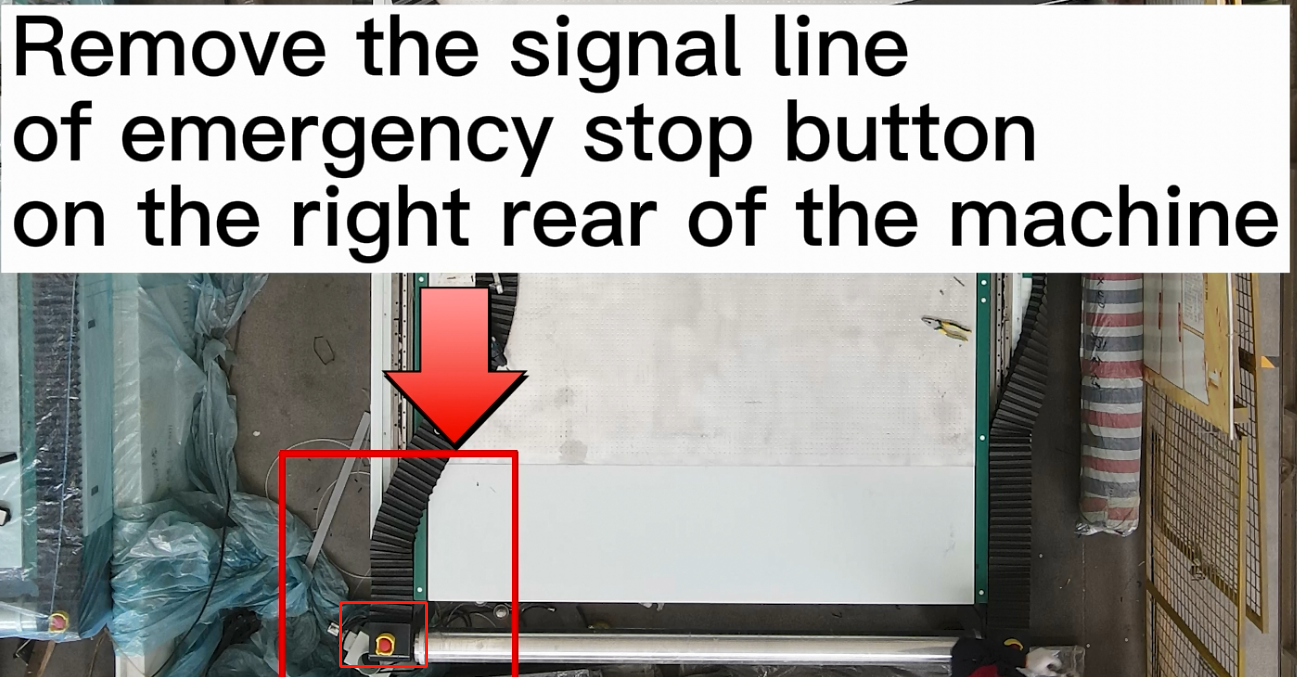

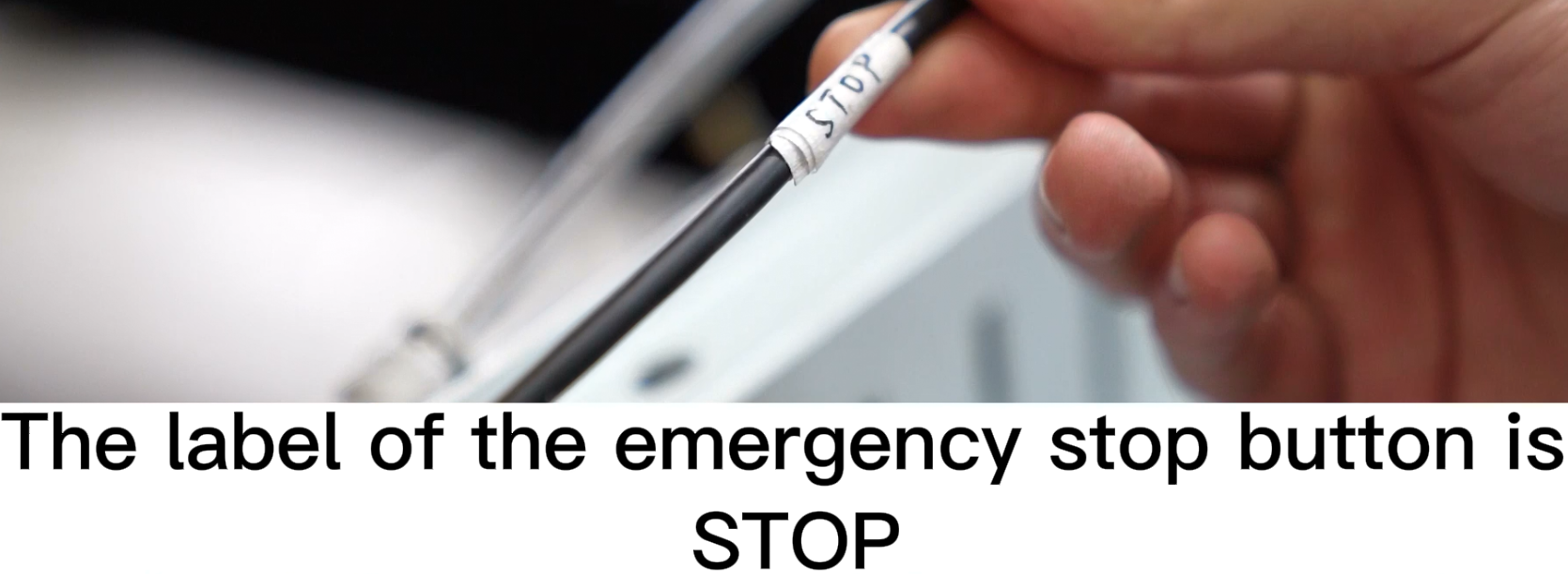

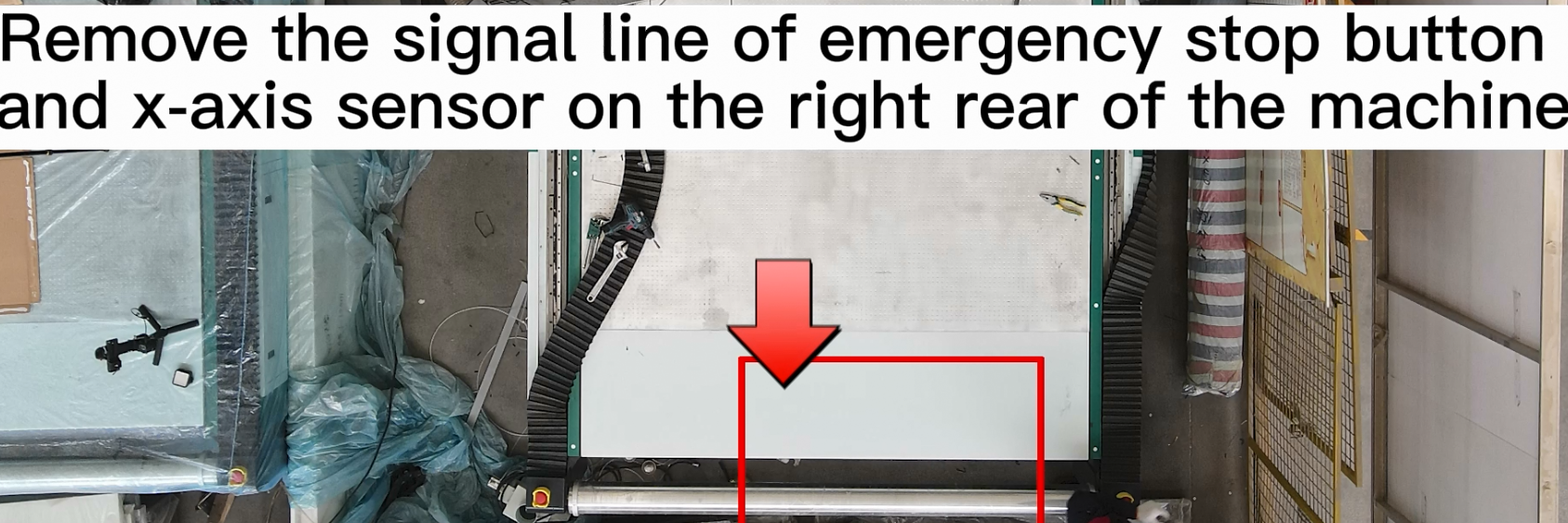

8. Remove the emergency stop signal line on the right rear, the emergency stop signal line is marked as STOP (when the goods are received, connect the white to white and orange to orange)

9. Remove the emergency stop and X-axis limit on the left rear side of the machine. The limit line is marked XL, and the corresponding wiring colors are blue to white, green to black, and orange to brown.

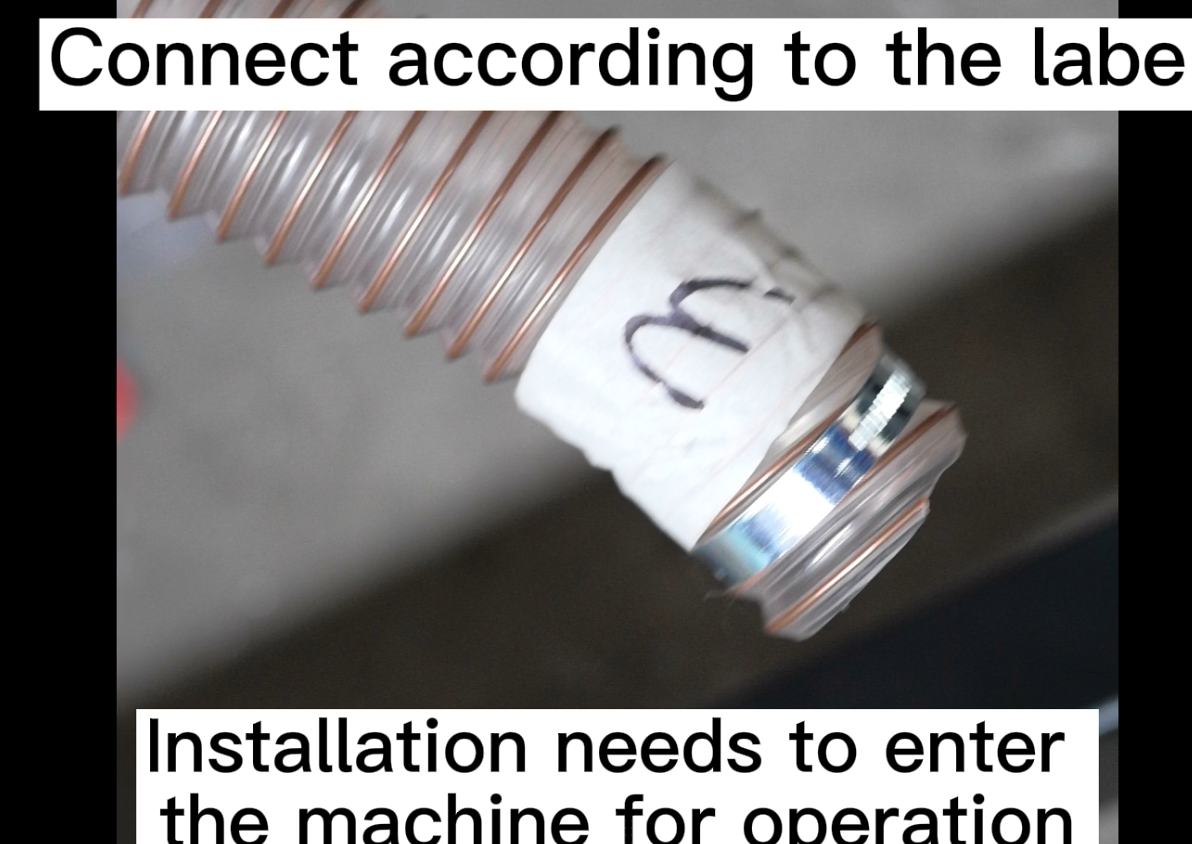

1. When installing, you need to enter the inside of the machine to operate, and connect according to the above label

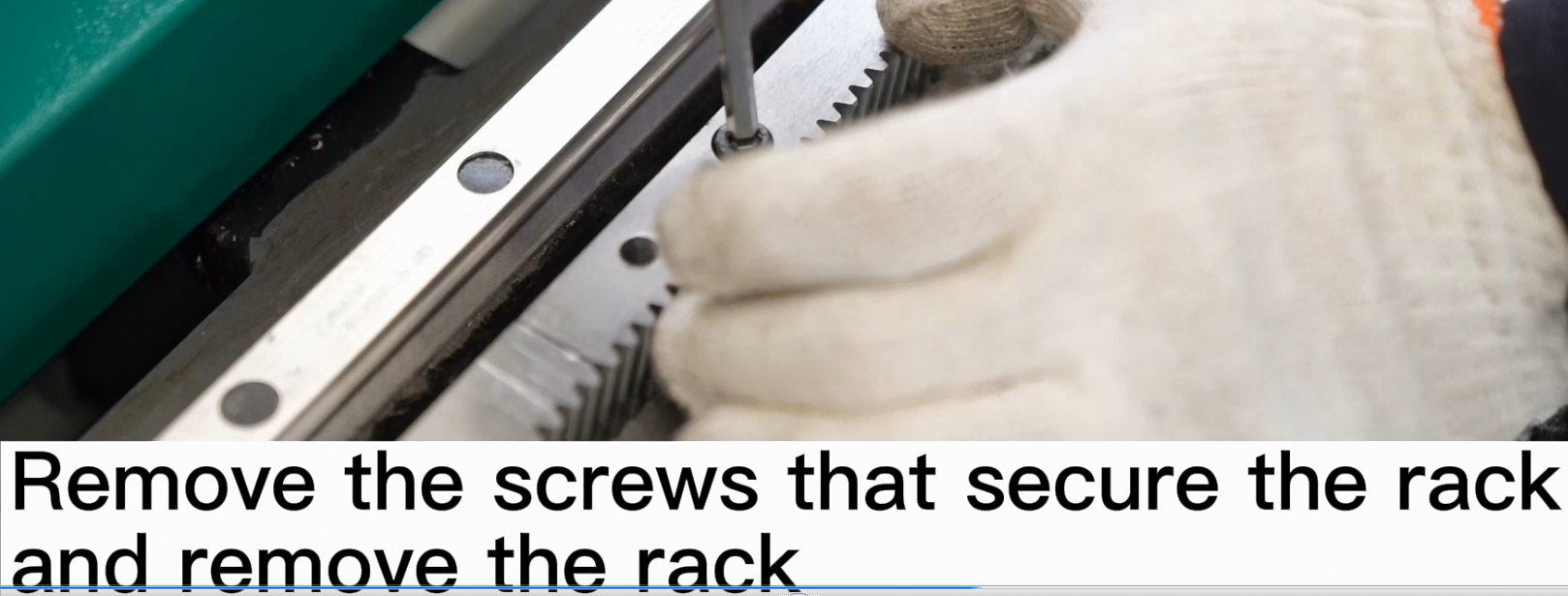

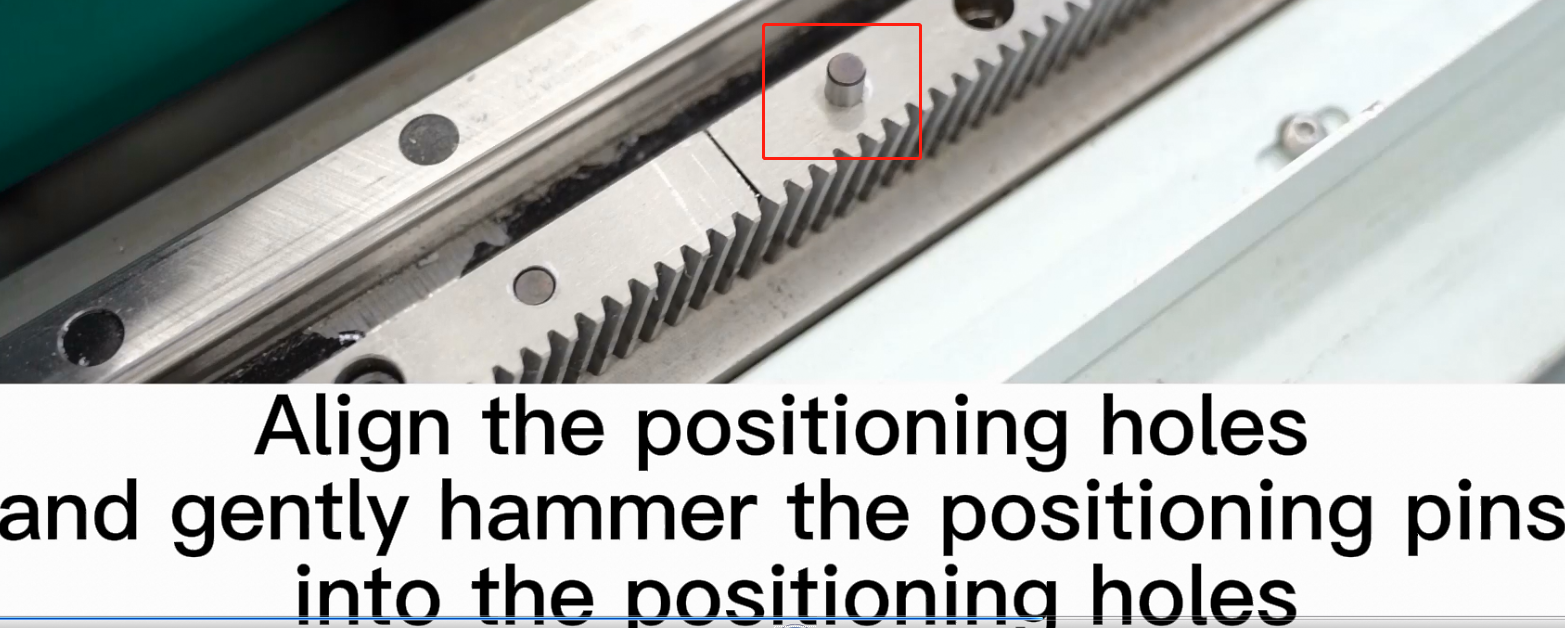

2. Remove the fixed screws and remove the rack (you need to align the positioning holes first and smash the positioning pins into the positioning holes during installation)

3. Fix the screws removed from the rack to prevent missing parts after the delivery. You need to remove the screws during installation, and then install the rack to fix it.

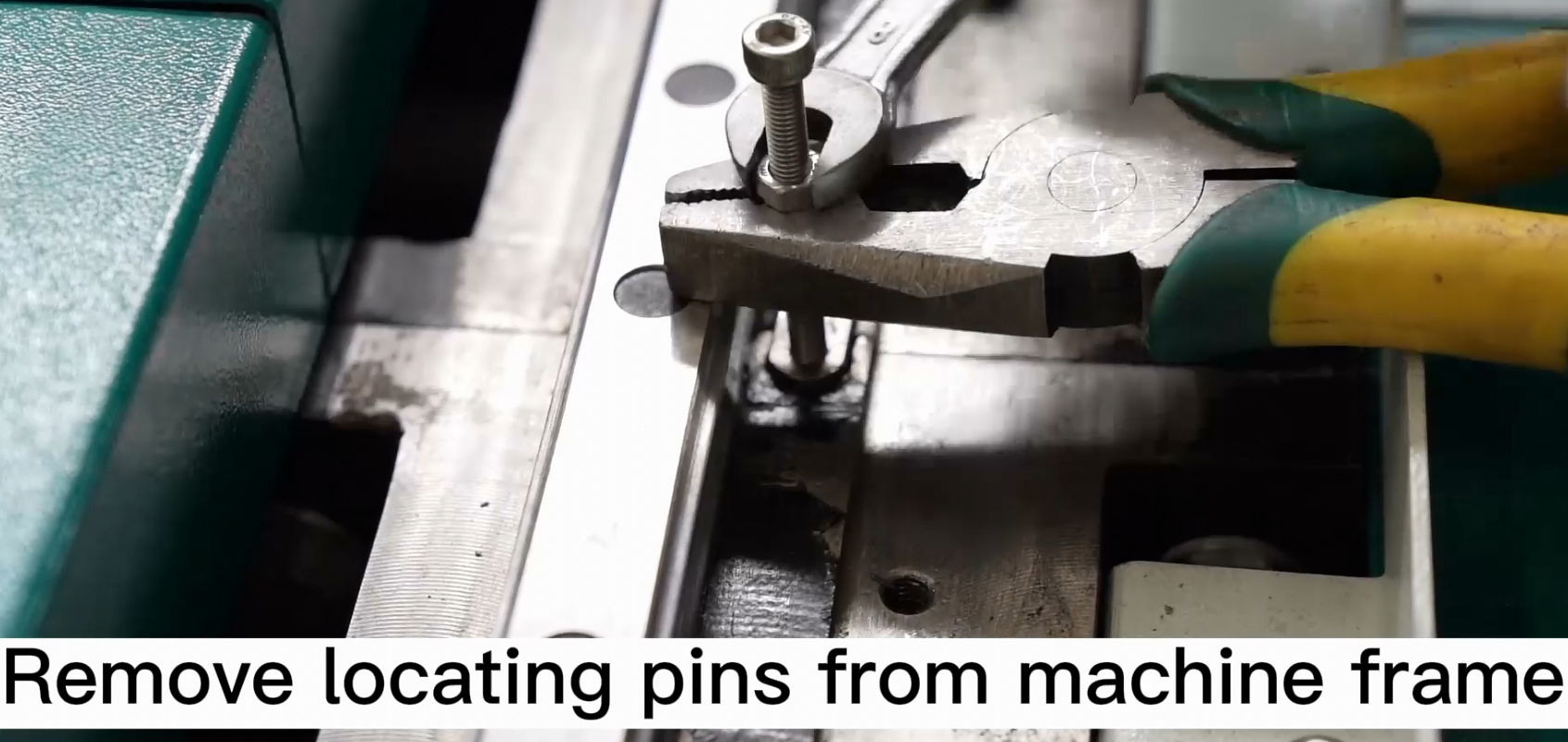

4. Remove the frame positioning pin I is the right side, II is the left side, and then smash the positioning pin into the groove, the positioning pin and the corresponding rack will be packed together

5. Remove the plastic cover on the sheet metal, loosen the screws inside to remove the sheet metal, loosen the screws and nuts of the fixed frame, and pull the upper part to complete the disassembly

1. Every working day must clean up the dirt of the machine tool and guide rails, keep the machine bed clean, turn off the air source and power supply when off work, and drain the remaining air in the machine tool tube belt.

2. Regularly check the straightness of the track and the verticality of the machine, and if it is found to be abnormal, it will be maintained and debugged in time.

3. Pay attention to observe whether there is lubricating oil on the machine's horizontal and vertical direction and the surface of the rack, and add lubricating oil in time.

4. If you do not use the machine for a long time, please turn off the power of the machine to prevent non-professionals from operating it.

5. Regularly check whether the transmission part is loose, check the meshing of the gear and the rack, and adjust it according to the situation.

6. Regularly check whether the performance of all switches can be used normally, and replace them if they are damaged.

7. Check and clean the air circuit and replace the aging air circuit.

8. Regularly check whether each valve and pressure gauge are working properly.

9. Regularly check whether there is dust in the control cabinet and drive cabinet, and whether the fastening screws are loose. If there is dust, use a vacuum cleaner or a blower to clean it.

1. AOYOO rack welding CNC cutting machine after the arrives at home, make sure that the equipment is in good condition and the accessories are complete.

2. How many volts is the power consumption of the equipment, and the voltage must be stable at how many volts, otherwise, a voltage stabilizer must be installed.

3. After receiving the installation of the rack welding CNC cutting machine, turn on the power to check whether all parts of the machine can operate flexibly and whether the fasteners are loose.

4. Turn on the power, check whether the machine can operate normally, and adjust it in time or contact us if there is any situation.

5. When cutting the sample, adjust the machine according to the hardness of the product material, and adjust it slowly until the desired effect is cut.

6. During the cutting process, observe whether the height adjustment system and the dust removal system are working normally. If there is any abnormality, please stop the machine immediately and troubleshoot.

7. Before shutting down after get off work every day, please return the system to the main menu, raise the cutter head to the highest position, return the equipment to a safe position, vent the remaining air in the pipeline, turn off the system power supply and then turn off the main power supply.

8. Do not touch the moving parts of the machine with your body and limbs while the machine is running to avoid injury. The power supply should be cut off when the equipment is maintained.

9. In the event of an unexpected power failure, please turn off the main power switch in time.

Through the above introduction, I believe you have a general understanding of the assembly, daily maintenance and instructions of the rack welding CNC cutting machine. The application range of CNC cutting machines is increasing, and your choices are also increasing. If you want to better cut and more refined products, please do not hesitate to choose Aolai. I guarantee that the AOYOO CNC cutting machine sold can meet all your needs. And we can introduce you all the contents of the machine in detail. Looking forward to your news!

If you want to know more about performance issues, please leave a message , we will have a professional staff contact you.

E-mail:info@aolcnc.com

phone:+86-18560162709

WhatsApp /微信:+8618560162709

youtube:https://www.youtube.com/channel/UCctbMXFvompG-41Wecb1mpw

website:https://www.aoyoocut.com/

Facebook:https://www.facebook.com/AOYOOCUTTER