ASSURANCE

Kraft paper is used as a packaging material, with high strength, brownish yellow color, and a wide range of uses. There are differences between roll paper and flat paper, as well as single-sided, double-sided and striped. The main quality requirements are flexibility and firmness, high burst resistance, and can withstand greater tension and pressure without breaking. Kraft paper has high tensile force, and has single light, double light, stripe, no grain, etc. Mainly used for wrapping paper, envelopes, paper bags, etc. and printing press cylinder lining.

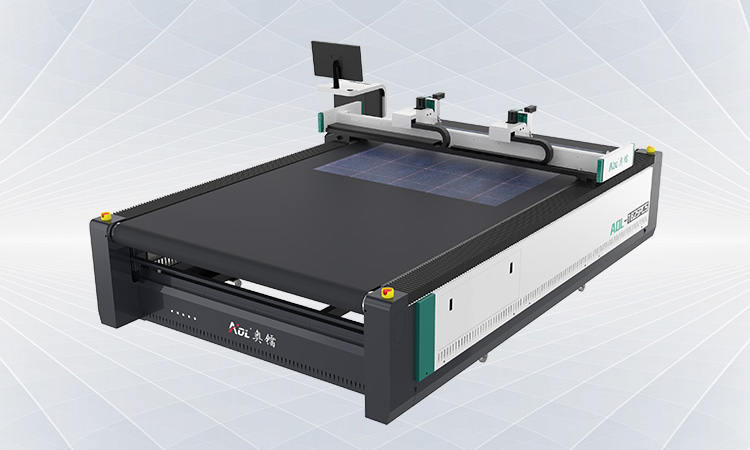

Due to the wide range of uses, the popularity is also increasing, and the demand is also increasing. Of course, under this trend, a number of kraft paper manufacturers have been able to develop. The shortcomings of manual cutting are CNC cutting machines. It has been developed and updated, and now more and more manufacturers use kraft paper cutting machines to cut materials.

The kraft paper cutting machine adopts the cutting method of the blade. At present, there are common methods of manual cutting and laser cutting. First of all, the efficiency of manual cutting is too slow. There is also the waste of materials. If it is manually cut, it will not be so accurate in material drawing, and there will be a lot of scraps. At the same time, the labor cost has risen sharply, while the cost of the automated production line has dropped significantly. The cost advantage makes the company give priority to the production line with a higher degree of automation when expanding production, and has the motivation to transform the original production line.

Then, friends who have used laser cutting machines will have a certain understanding. Laser cutting uses high temperature, which is no problem in terms of cutting speed and cost. Flexible materials such as leather are not so perfect. On the one hand, the material of flexible materials is relatively soft, and the high temperature of the laser will damage the material, causing unnecessary losses, and some will leave a bad smell. The environment has a certain degree of pollution, but it is not the most environmentally friendly.

Therefore, to sum up the above, it is relatively better to choose a blade cutting machine. This is also the feedback sent to me by AOL customers. After using the blade cutting machine, I realized that it is so easy to use.

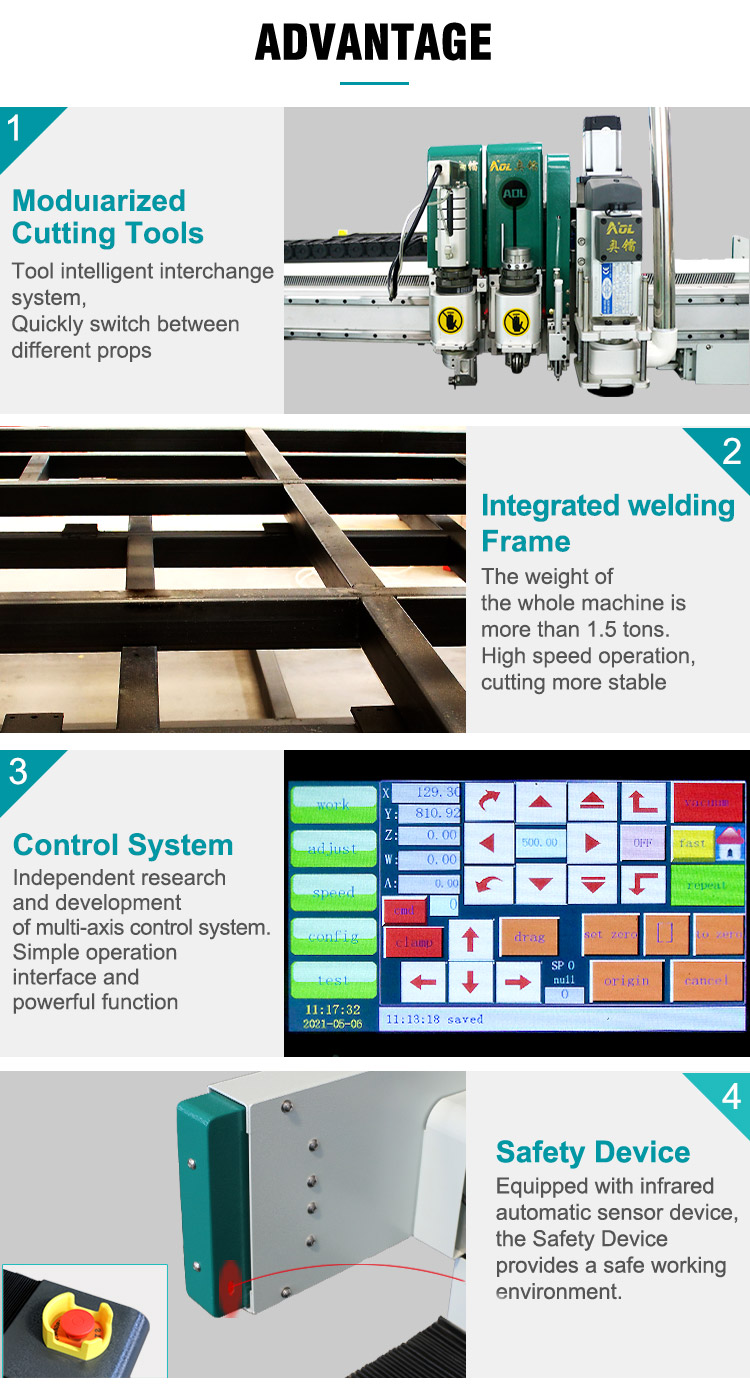

Let's talk about what everyone is most concerned about, how to choose a blade cutting machine? Whether you're looking to replace a device or have manufacturing ideas, here are a few things to keep in mind.

1. Cutting speed

This is one of the key factors that directly affects the benefits of the project. The speed of the kraft paper cutting machine determines the production efficiency. If the production cannot keep up with the efficiency, it cannot keep up. We use the cutting machine to improve the output, quality and reduce costs. This point It is very important to see the full set of demos when purchasing.

2. Cutting stability

It can be measured intuitively by the accuracy of kraft paper cutting. The defective rate of kraft paper cut by laser cutting is finer than that of traditional mechanical cutting, and the blade cutting machine is more superior than laser. It is necessary to know that the smaller the defective rate, the better, the more stable the machine, the better, which can avoid unnecessary Loss.

3. Machine maintenance cost

This is also very important. At present, most of the kraft paper laser cutting machines on the market use CO2 gas as the working medium. The continuous use time of a single air exchange and the cost of air exchange, as well as the cost of laser replacement, must also be considered by users. Compared with the blade cutting machine, it is better. AOL can freely replace the cutter head, and choose the most suitable one according to the different materials. Regular inspection and maintenance of the machine can also reduce maintenance costs.

4. Machine brand

The kraft paper blade cutting machine is actually the application result of the cutting machine extended to the packaging industry. Due to the wide application in the packaging industry, the machine manufacturer needs to continue to improve it according to the actual use needs of the packaging industry, so try to choose a brand with R&D strength, whether small manufacturers are From the performance of the machine or the after-sales service, it is not the best.

5. The price of the machine

Everyone wants to choose a cost-effective product. The actual inspection by professionals has confirmed that there are already many friends around who have suffered a big loss by purchasing low-priced machines. You need to know how to look at the performance of the machine. In the case of guarantees in all aspects, of course, the more favorable the price, the better, right, if you just think about the price and foreign machines, and don’t look at other things, you will suffer.

The above five points seem to be very simple, but once you can understand it, there is no problem in purchasing equipment. Many foreign customers will also tell me some experience after use, and they also recognize AOl. On the one hand, It is because the quality and practicability of the equipment are not inferior to other old brands, and the cost performance is higher than theirs, and there is nothing to say about the after-sales service. Therefore, we also have agents in many countries, and good machines can speak. If you happen to need it, it is recommended that you learn about our cutting machines.