ASSURANCE

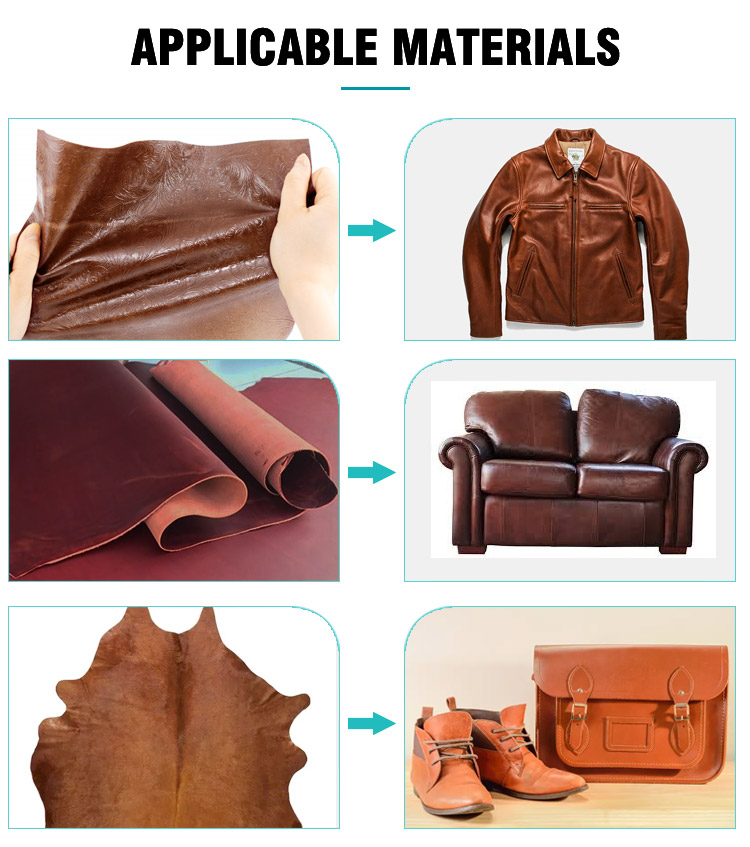

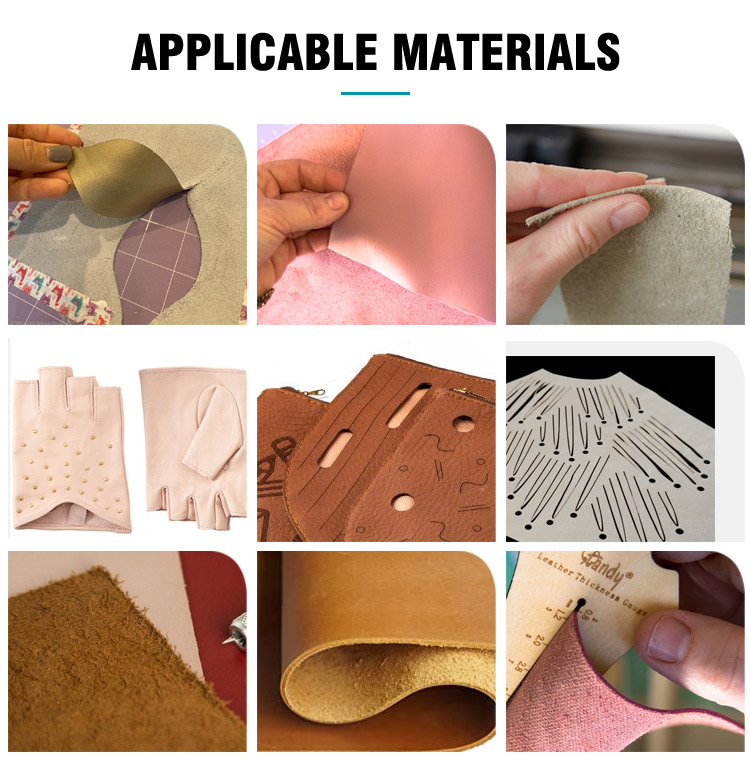

Leather is an animal skin that has been denatured and is not perishable, which is obtained through physical and chemical processing such as dehairing and tanning. Leather is composed of natural protein fibers tightly woven in a three-dimensional space. There is a special grain layer on the surface, which has natural grain and luster, and feels comfortable. Leather means that animal fur is chemically treated to become leather with a certain degree of flexibility and air permeability, and is not easy to rot, also known as leather. The leather used for clothing mainly includes sheepskin, pigskin, cowhide and horseskin. When cutting leather, a professional leather fabric cutting machine is required. It is recommended that you use the AOYOO leather fabric cutting machine. This cutting machine can not only cut a variety of The pattern, and the cutting is neat and flawless. You deserve it!

The leather industry covers major industries such as tanning, shoemaking, leather clothing, leather goods, fur and their products, as well as supporting industries such as leather chemicals, leather hardware, leather machinery, and accessories.

At present, our common leather types include genuine leather, recycled leather, artificial leather, and synthetic leather.

Genuine Leather:

"Leather" is a common word in the leather product market, and it is a customary name for natural leather to distinguish synthetic leather. Animal leather is a kind of natural leather, which is what we often call genuine leather. It is a leather material with various characteristics, strength, feel, colors and patterns after tanning and processing in a leather factory from animals (raw hides). It is a necessary material for modern leather products.

Regenerated leather:

After crushing various animal waste skins and leather scraps, it is made by mixing chemical raw materials. Its surface processing technology is the same as that of leather trimmed leather and embossed leather. Its characteristics are that the edges of the leather are relatively neat, the utilization rate is high, and the price is low; but the leather body is generally thicker and weaker, so it is only suitable for making cheap briefcases and trolley bags. , Cue cover and other stereotyped craft products and cheap belts, the longitudinal section of the fiber structure is uniform, and the coagulation effect of the fluid mixed fiber can be recognized.

Artificial leather:

Artificial leather is also called imitation leather or rubber, which is a general term for artificial materials such as PVC and PU. It is made on a woven fabric base or a non-woven fabric base by foaming or laminating PVC and PU of various formulations. It can be processed according to different strength, abrasion resistance, cold resistance, color, gloss, and pattern. Patterns and other requirements are processed and made, with the characteristics of a wide variety of patterns, good waterproof performance, neat edges, high utilization rate and relatively cheap price compared to real leather.

Synthetic Leather:

Synthetic leather is a plastic product that simulates the composition and structure of natural leather and can be used as its substitute material. The surface is mainly polyurethane, and the base material is a non-woven fabric made of synthetic fibers such as polyester, cotton, and polypropylene. The front and back sides are very similar to leather and have a certain degree of air permeability. It is characterized by beautiful luster, not easy to mold and moth-eaten, and is closer to natural leather than ordinary artificial leather. There are many varieties. In addition to the common characteristics of synthetic fiber non-woven fabric base and polyurethane microporous surface layer, various synthetic leathers have different non-woven fiber varieties and processing techniques. Synthetic leather has a smooth surface, thin thickness, uniform color and strength, and is superior to natural leather in terms of water resistance, acid and alkali resistance, and microorganisms.

1. Lightweight and warm, graceful and luxurious. Animal skin is often said that leather made of leather shoes or leather clothes has good air permeability and flexibility, which makes people feel comfortable.

2. It has durability, can be processed in three dimensions, is easy to dye, has good ventilation, does not have static electricity, has animal pore tissue, can permeate steam, absorb sweat, and keep warm.

3. Dyeable hanging, with plasticity, rich texture and color, neat cut, high strength.

4. The surface texture is natural, smooth and fine, with good hand feeling and touch.

1. AOYOO leather fabric cutting machine has the characteristics of non-scorching, burr, smokeless and tasteless when cutting leather materials.

2. Use industrial vision system to quickly scan leather and automatically identify contours and defective parts.

3. Independent research and development software, one-key import, intelligent typesetting, automatic loading and unloading and cutting, improve the maximum utilization of materials,

4. A variety of tools can be switched at will, cutting and punching marking can be completed at one time.

5. The leather fabric cutting machine has a partition adsorption function, which can select the best adsorption range according to the cutting position, and the adsorption force is increased by more than three times.

6. Using Japanese Panasonic servo motor, the production efficiency is increased by more than three times, saving a lot of manpower.

7. The transmission adopts Swedish rack and pinion transmission, and the accuracy is controlled at 0.1mm.

I believe you have learned a lot about leather-related knowledge by reading this article, and you also have a preliminary understanding of leather fabric cutting machines. I believe that you have already felt the strength of our company, and there will be many questions. Please click to contact us to ask your questions. Professionals will answer all questions for you in the first time. Looking forward to your news!

E-mail:info@aolcnc.com

phone:+86-18560162709

WhatsApp /微信:+8618560162709

youtube:https://www.youtube.com/channel/UCctbMXFvompG-41Wecb1mpw

website:https://www.aoyoocut.com/

Facebook:https://www.facebook.com/AOYOOCUTTER