ASSURANCE

Inflatable boats are inflatable boats, widely used in water leisure, entertainment, fishing, fishing and other water operations, with the advantages of light and multi-functional. Compared with traditional boats, inflatable boats are safer and can adapt to a variety of waters. Most of the materials used in inflatable boats are polyester fiber fabrics, which are coated with PVC special materials on both sides. This material is completely airtight in water, wear-resistant and durable, resistant to salt, alkali and sunlight, and has high strength. Anti-aging properties. The quality of the hull determines the safety performance of the inflatable boat. When cutting this type of material, you need to use a professional inflatable yacht cutting machine. What are the benefits of using it, let me explain it to you one by one!

The inflatable yacht cutting machine is drawn by computer, and transmitted to the machine control card after internal data processing. The control card then sends a command pulse signal to the servo drive. The drive drives the servo motor to move to achieve the movement of the machine, and at the same time sends signals to the cutting tool. , cutting the raw material.

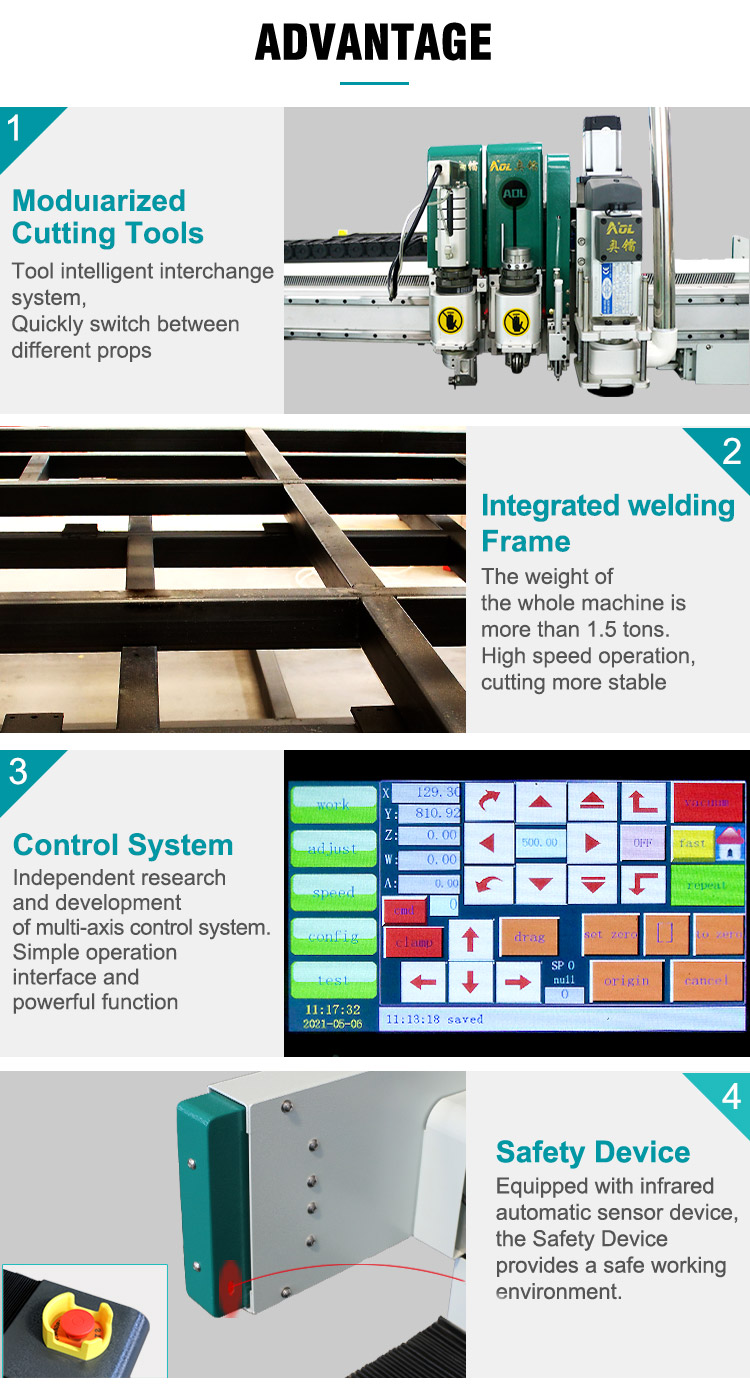

1. The flatness of the table is detected by a high-precision distance detector, and the plane is corrected in real time through the software to achieve a perfect cutting effect.

2. Adopt high-performance multi-axis motion control system, easy maintenance, low cost, and provide personalized development services

3. Graphics in AI, CorelDraw, CAD and other formats can be imported into cutting software to simplify the workflow of structural and graphic designers.

4. Super strong wind and strong suction, you can choose the size of the vacuum adsorption area, which greatly reduces power consumption

5. The high-definition CCD camera realizes automatic positioning and sleeve cutting of various materials, eliminating the problems of inaccurate manual positioning and printing deformation.

6. Fast and simple automatic tool setting system, using sensors to accurately detect the tool, greatly improving the tool setting efficiency.

1. One-click import of self-developed software, ordinary workers can work skillfully within 2 hours.

2. The efficiency is equivalent to 4-6 manual workers, the floor space is small, the error is less than 0.1MM, and the cutting quality can be guaranteed.

3. Quick tool change system provides a variety of tool options for various materials.

4. With the super nesting software, the material utilization rate is increased by more than 10%.

5. The whole machine is equipped with anti-static system to protect the safety of personnel to the greatest extent.

6. Aluminum-magnesium alloy adsorption platform, durable and not deformed.

1. Outer packing: Standard sea export plywood box.

2. Inner packing: stretchable film and plastic film to prevent moisture.

If you have special requirements, we can negotiate amicably; if you want to know more, please contact us.

E-mail:info@aolcnc.com

phone:+86-18560162709

WhatsApp/Wechat:+8618560162709

YouTube:https://www.youtube.com/channel/UCctbMXFvompG-41Wecb1mpw

website:https://www.aoyoocut.com/

Facebook:https://www.facebook.com/AOYOOCUTTER