ASSURANCE

We often see artificial turf in various sports venues, which are widely used in special competition venues for hockey, baseball, and rugby, public practice fields for football, tennis, golf and other sports, or as ground pavement to beautify the indoor environment.

In the construction process, the lawn is first cut into pieces, and then the ground is tiled according to the site, and there should be no excessive gaps between the lawns. Therefore, the requirements in the cutting process are also relatively strict.

1. Acceptance of the project, weeds are removed, and if there is any unevenness, it should be repaired and leveled in time. The construction site must be clean to ensure the cleanliness of the environment and construction quality.

2. For measurement and stakeout, use theodolite or other precise measuring instruments to measure whether the surrounding facilities conform to the size of the sports field.

3. Cut the turf according to the measured size, roll it up and bundle it for later use.

4. The turf is laid on the ground, the turf should be overlapped by 3~8mm, and the seam should be no more than 3mm.

5. Clean the bottom surface of the turf, the interface cloth, etc. to be bonded, and the surface is dry and free of moisture.

6. The ambient temperature should be selected above 5 ℃ for construction, and it is cured after applying glue.

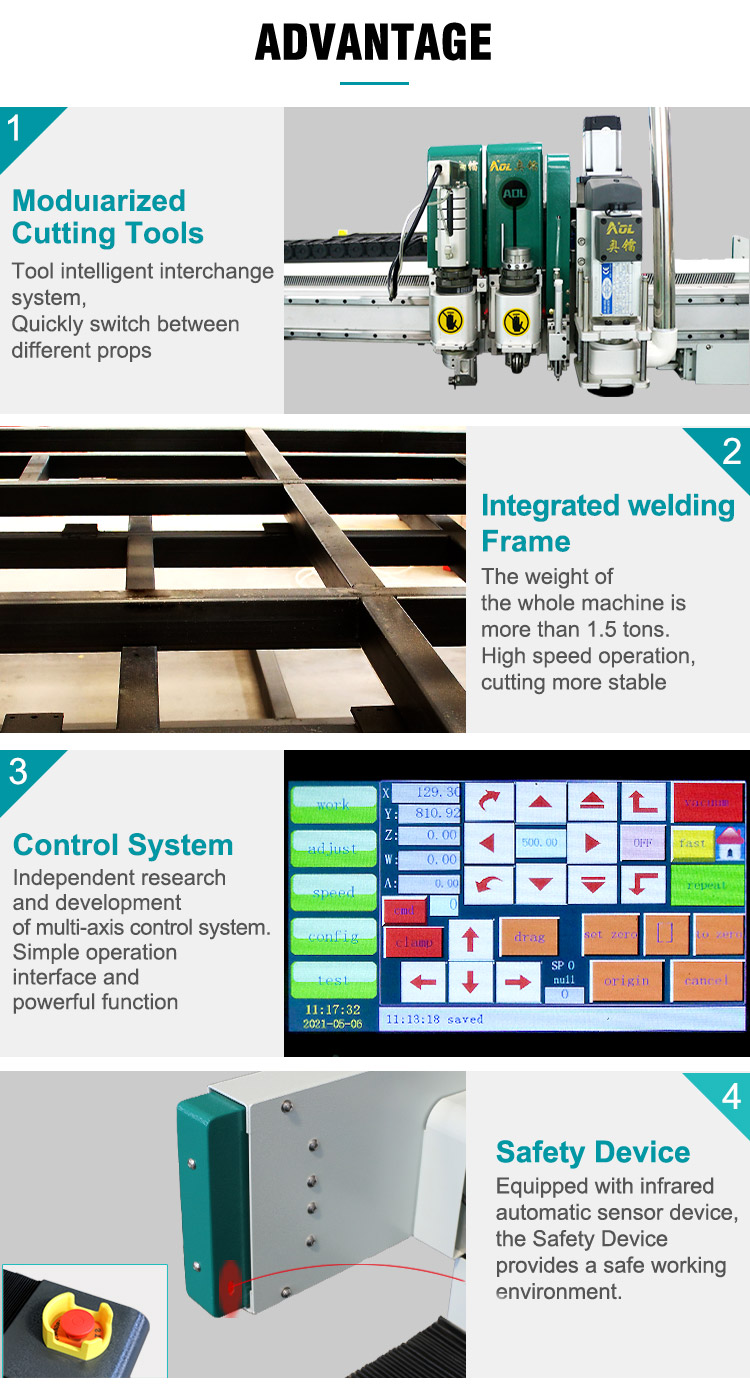

For the cutting mentioned above, many manufacturers still use manual cutting. However, for the reasons of low efficiency and high waste of small batch customized manual cutting, many manufacturers choose AOL's artificial turf cutting machine, which can not only ensure high-precision and high-efficiency cutting , but also save labor costs.

Ordinary manual cutting accuracy is ±0.5mm, and the cutting utilization rate is above 60%; the cutting speed is slow, the cutting edge is seriously damaged, the color matching product accuracy is low, and the rejection rate is high; according to the current market price, a worker's one-day The cost is 200-300 RMB/day.

The equipment accuracy of the artificial turf cutting machine is ±0.1mm, and the utilization rate of cutting materials is as high as 85%; the special-shaped cutting is convenient and quick, and the cutting avoids damage to the grass; the power consumption per hour is about 11 degrees.

The artificial turf cutter also has an infrared sensing device, which can ensure the safety of personnel to the greatest extent.

Our machine adopts Japanese Panasonic servo motor, which can guarantee continuous power supply for a long time.

The weight of the whole machine is more than 1.5 tons, and the high-speed operation does not vibrate.

The equipment must undergo 72 hours of uninterrupted high-load proofing and trial cutting before leaving the factory.

AOYOO is a sub-brand under AOL CNC Cutting Equipment.AOL is a famous CNC equipment factory. AOL mainly produce CNC Knife Cutting Machine, Cutting Plotter, CNC Cutting Table and so on. We, as a high-tech enterprise, engaged in research, manufacture and sell the CNC cutting machine and relevant products.

AOL has gained CE certificate, FDA and ISO certificate. Company successfully produce AOL series products of more than 50 sorts, which enjoy good reputation and support. Excellent quality and fast service makes our products spread all over the world as Europe, America, Middle east and South of Asia.

If there is anything else you want to know, please contact us, and we will have a dedicated person in charge to answer it for you!