ASSURANCE

More and more companies have joined various industries related to carbon fiber materials, and carbon fiber is an important reinforcing material in advanced composite materials and is widely used in many fields. Many people have raised questions, asking us whether AOYOO produces carbon fiber CNC cutting machines and whether it can cut carbon fiber materials in their industry. Now I will tell you the answer: of course! It can cut not only carbon fiber materials, but also materials in various industries such as carpets, cartons, packaging, leather, and clothing.

Carbon fiber is converted from organic fiber through a series of heat treatment. It is an inorganic high-performance fiber with a carbon content of more than 90%. It is a new material with excellent mechanical properties. It has the inherent characteristics of carbon materials and the softness of textile fibers. Machinability is a new generation of reinforced fiber.

Carbon fiber is a kind of special fiber mainly composed of carbon elements, and its carbon content varies with different types, generally more than 90%. Carbon fiber has the characteristics of general carbon materials, such as high temperature resistance, friction resistance, electrical conductivity, heat conduction and corrosion resistance, etc. However, unlike general carbon materials, its shape is significantly anisotropic, soft, and can be processed into various The fabric exhibits high strength along the fiber axis. Carbon fiber has a small specific gravity, so it has a high specific strength.

Carbon fiber is an indispensable material in modern aerospace technology and is widely used in rockets, space stations, satellites, missile weapons and other fields. The application of carbon fiber composite materials to the missile body and engine shell of strategic missiles can greatly reduce the weight and increase the range and assault capability of the missile. The application of carbon fiber to the spacecraft can greatly reduce the structural weight, which can significantly improve the fuel efficiency. Airplanes, satellites, rockets and other space vehicles made of composite materials made of carbon fiber and plastic have low noise, low mass and low power consumption, which can save a lot of fuel. According to reports, for every 1kg reduction in the mass of the spacecraft, the launch vehicle can be reduced by 500kg.

This material is the focus of material selection for the new generation of high-speed rail train bodies. It can not only make the rail train body lightweight, but also improve high-speed running performance, reduce energy consumption, reduce environmental pollution, and enhance safety. Carbon fiber composite materials are used in rail transit. Field application has gradually become a trend.

The most downstream applications of carbon fiber are in the sports and leisure field, and bats and racket frames appear more in sports applications. Sports products such as cue sticks, fishing rods, tennis rackets, badminton rackets, ice hockey sticks, bicycles, windsurfing masts, and nautical hulls are all important applications of carbon fiber. Carbon fiber is also used in other sports and leisure sports such as boating, rowing, and watercraft.

Carbon fiber composite materials are excellent materials for making medical bed boards. Medical bed boards made of carbon fiber composite materials have a ray transmittance of over 97% and clearer imaging. Compared with traditional medical bed boards, the weight of carbon fiber medical bed boards is reduced by about 45%. Moreover, the chemical properties are stable and the corrosion resistance is strong. Even if it is in long-term contact with common medical items such as alcohol, drugs, blood, etc., it will not corrode, and it is easy to clean.

Carbon fiber materials have also become a material favored by automobile manufacturers, and they have begun to be widely used in automobile interior and exterior decoration. As an automobile material, carbon fiber has the biggest advantage of light weight and high strength. The weight is only 20% to 30% of steel, but the hardness is more than 10 times that of steel. Therefore, the use of carbon fiber materials in automobile manufacturing can make breakthroughs in the lightweight of automobiles and bring social benefits of energy saving. At present, there are many carbon fiber composite cars on the market, which can reduce the weight of cars by 60% compared with ordinary steel cars. Compared with ordinary cars, they are lighter in weight, fast, and low in fuel consumption. Under the same fuel consumption, carbon fiber cars can drive at least 50 kilometers per hour.

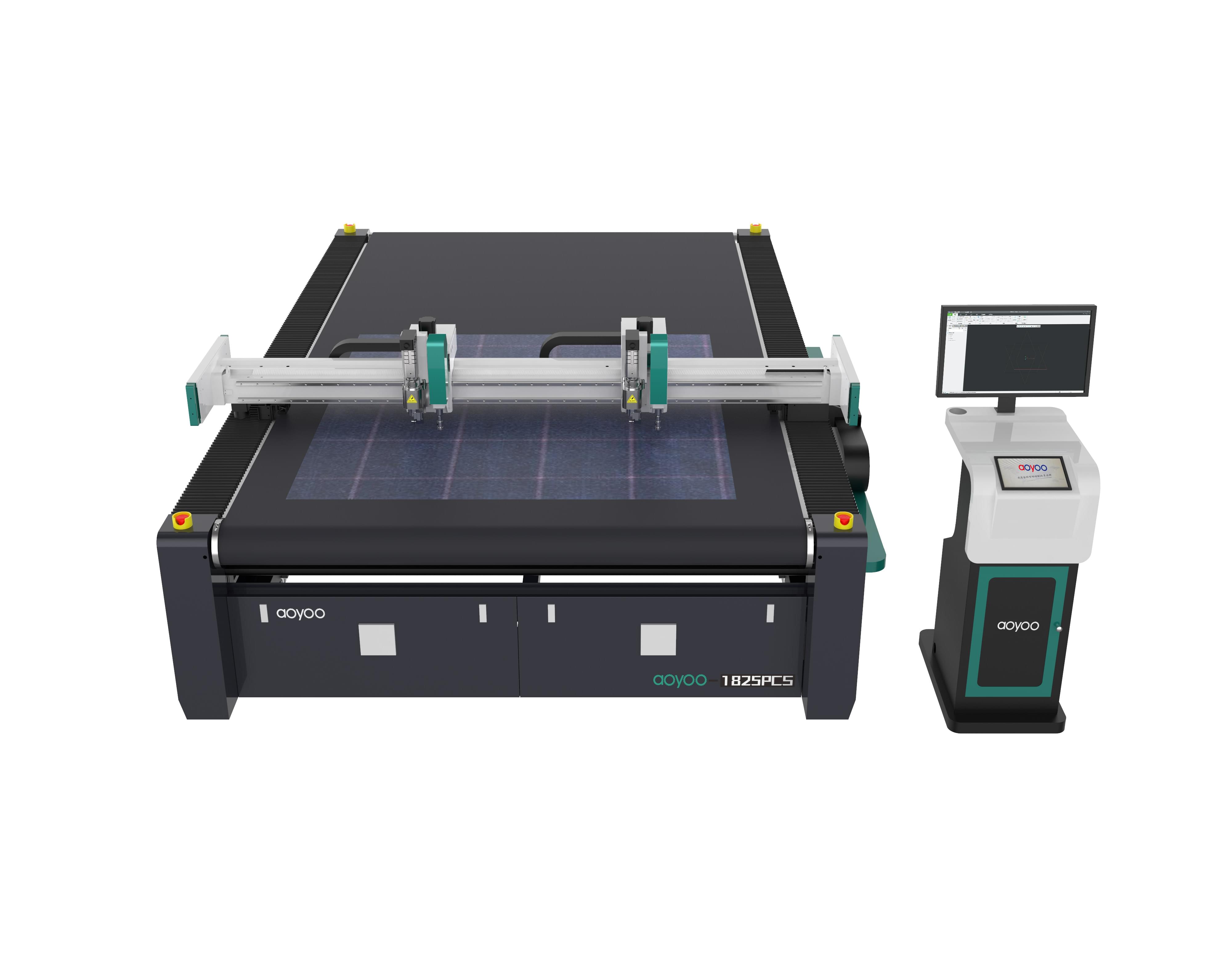

1. Our self-developed software has a one-click import function, and any worker can be proficient in taking the job within 2 hours

2. Japan's Panasonic servo system increases production efficiency by more than four times

3. Automatic loading and unloading, saving time and effort

4. The unique quick tool change system realizes the easy cutting of various soft and hard materials

5. The cutting surface is flat and flawless, which can realize multi-layer cutting

I believe you have learned the details of carbon fiber materials and carbon fiber CNC cutting machine in detail through reading this article. In the choice of carbon fiber material cutting machine, AOYOO CNC cutting machine is definitely your best choice! If you want to know more machine-related questions, please leave a message, we will have professional staff to answer you, and look forward to your reply!