ASSURANCE

The middle layer of the pre-insulated composite air duct is made of phenolic foam, and the upper and lower layers are made of embossed aluminum foil, which are widely used in air conditioning systems. Phenolic composite air duct has become the best air duct material to replace galvanized steel and glass fiber reinforced plastic due to its advantages of good thermal insulation, good noise reduction and light weight. It is suitable for special places such as industrial and civil buildings, hotels, hospitals, office buildings and so on.

In the construction of pre-insulated pipes, workers first need to draw engineering drawings according to the construction site, decompose the engineering drawings, and determine the installation positions of air-conditioning equipment and air duct components. The disassembly and assembly air duct system is divided into straight air ducts and elbows. Variable diameter, tee, cross and other shapes. Secondly, the specifications and quantity of air ducts are calculated by experienced workers, that is, the reasonable length and quantity of straight air ducts and special-shaped air ducts, and the rectangles, T-shapes, elbows, reducers, etc. Loft out different pipes, then use a paintbrush to draw cutoffs, V-grooves, and 45-degree slashes.

Finally, workers use a knife to cut off excess material along the marked lines. First put the board on the workbench, and then fix the ruler in parallel in a suitable position. The worker holds the tool, leans the reference edge of the tool against the ruler, and presses the planing surface against the board. The reference line of the tool is aligned with the lofting line. Then push the tool forward or pull it back.

1. Low efficiency: Due to the different construction environment, the size of the pipe cut each time is different, and a fixed pattern cannot be formed. Every time during processing, workers are required to draw lines according to the measured data;

2. High reliance on skilled workers: Due to the changeable shapes and sizes of pre-insulated pipes, mature skilled workers are needed to ensure the correctness of data and perfect cutting effect.

3. Difficult to process: It is necessary to make phenolic air ducts of different shapes such as rectangles, T-shaped, elbows, etc., and a variety of tools are needed to meet the measurement, single-side bevel cutting, slotting and straight-line cutting processes.

1. Equipped with professional duct drawing software. Built-in hundreds of pipeline models, you only need to input data to get the graphics you want to process. Customers can view the effect of the pipeline model in real-time in 3D mode. The software automatically decomposes three-dimensional graphics into plane graphics without manual calculation. And it can automatically nest materials according to the size of the plate to improve the utilization rate of materials.

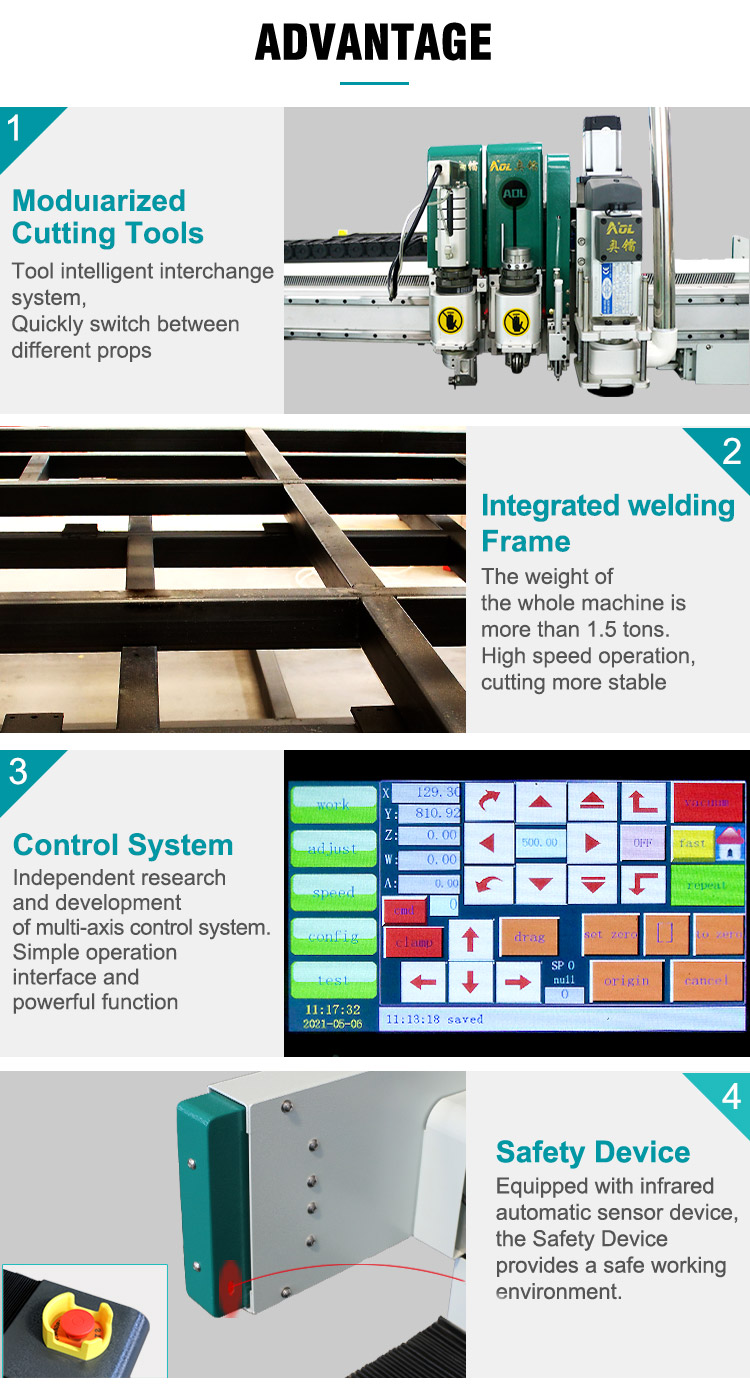

2. Equipped with a variety of processing tools. AOL pre-insulated pipe cutting machine is equipped with cutting, grooving and marking tools, which can complete 45° bevel cutting, grooving and marking work at one time to improve work efficiency. The operation is simple and can be operated by ordinary workers, reducing the dependence on skilled workers.

3. There is no dust in the cutting process. AOL pre-insulated pipe cutting machine is a more environmentally friendly processing method, the cutting section is smooth, no dust is generated during the processing, and there is no need to worry about the harm to the human body during the processing.

The above content is an introduction to the advantages of the pre-insulated pipe cutting machine. If there is anything else you want to know, please contact us in time, and we will give you a detailed answer as soon as possible!