ASSURANCE

The PTFE gasket cutting machine is extremely reliable in the accuracy of size and processing. The CAM special software suitable for PTFE gasket cutting is combined with a fully compatible control system. Order-based production is still small batch customization. The PTFE gasket cutting machine is completed with excellent cutting performance, and the production efficiency is increased by 10%, realizing a fast return on investment.

| chnical parameters | AOYOO-1625 |

| Effective working area | 1600*2500mm |

| Multi-function cutting head | The combination of Multi-function cutting head and holders, be with full cut, kisscut, creasing wheel,v-cut and laser red light positioning functions, CCD positioning, Camera extract large contour to cut |

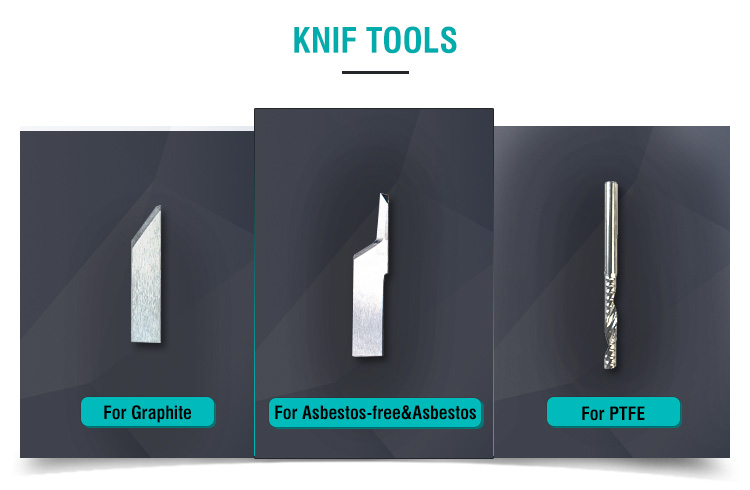

| Tools | Oscillating knife, Milling tool, pneumatic knife, V-cut, crease wheel, kiss cut, drag knife |

| Moving speed | 800-1500mm/s |

| Repeat precIsion | ±0.1mm |

| Interface | Enternet port |

| Control panel | LCD touch screen |

| Drive system | Imported servo motor, linear guid, synchronous belt, screw |

| Instruction system | HP- GL Compatible format |

| Rated power | 2. 2KW |

| Rated voltage | 220V |

| Cutting thickness | ≤50mm(According to different material) |

| Material fixed way | Vacuum adsorption |

| Auto feeding system | Acuum sucker adsorpting sheet |

PTFE seals, gaskets, gaskets. PTFE seals, gaskets, and gaskets are made of suspension polymerized PTFE resin. Compared with other plastics, PTFE has the characteristics of chemical corrosion resistance, and it has been widely used as a sealing material and filling material.

1. CAM special software developed by the gasket industry, professionally solve the problems of the gasket industry.

2. The cutting is equipped with pneumatic cutters and milling cutters to provide perfect cutting with high precision and high speed.

3. Using physical cutting method, safe and pollution-free working environment,

1. Self-developed one-key import software and layout optimization software, compatible with multi-format files,

2. Select Taiwan linear guide drive system, the accuracy error is stable at ±0.1mm

3. The whole machine is equipped with an anti-static system to provide a safe operating environment

4. Break the traditional cutting method, realize intelligent automatic cutting and save labor cost.

Our service

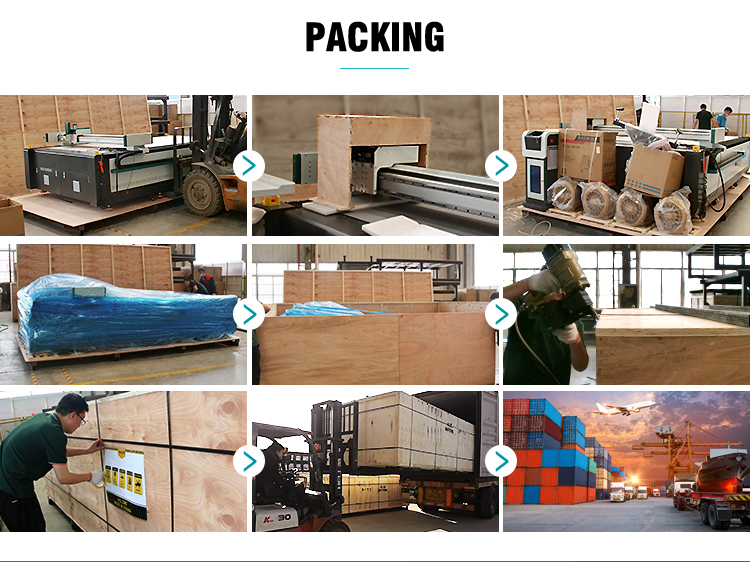

1. Outer packing: standard seaborne export plywood box.

2. Inner packaging: stretchable film and plastic film to prevent moisture. Soft material wrapping machine parts

3. Personalization: If you have special requirements for packaging, you can negotiate friendly.

In generally adopts the FOB delivery method, and the price is determined according to the delivery port and transportation distance you specify. Please leave a message for your message, and we have professional staff to calculate the price for you.

After-sales service of PTFE Gasket Cutting Machine

1. Our standard warranty period is calculated from the completion of the delivery. We provide you with a three-year warranty service and provide professional machine maintenance and maintenance.

2. The parts that are easy to wear (blade, countertop) are sold to users at the lowest price.

We have our own factory. After you place an order, we will start to make your PTFE cutting machine. At the same time, we will carry out reasonable delays based on the monthly order volume. Our delivery time is about 15-20 days on average. , If you want to specify a time, we can arrange a reasonable time to make the PTFE cutting machine you need.

AOYOO's main products include smart blade cutting machines, vibrating knife cutting machines and laser cutting machines. Our smart blade cutting machines are oriented to different markets. AOYOO has 14 years of experience in manufacturing cutting machines. We have provided automatic smart cutting machines to more than 2,000 users worldwide and provided professional industry material solutions. . If you encounter a problem with material cutting, welcome to leave us a message for free consultation!