ASSURANCE

1. Elegance, comfort and details precision play a primary role in furniture.

2. Leader in cutting foam, leather and man-made materials in single or multiple layers, AOYOO is able to offer a wide range of products studied to manufacture furniture in series or design items, such as beds, sofas, chairs and more.

3. The production includes systems to acquire and modify shapes, to scan leather contour and define quality areas, to automatically position the shapes on leather and synthetic materials and further cutting.

Specification of flatbed cutter carpet

Technical parameters / model | AOYOO-1625-ZS6 | AOYOO-1825-ZS8 | AOYOO-2125-ZS10 | Accept unconventional model customization | ||

Effective working area | 1600x2500mm | 1800x2500mm | 2100X2500 | |||

Multi-head optional | Double head optional efficiency doubled, double gantry optional, double head mutual shift optional, length can be customized | |||||

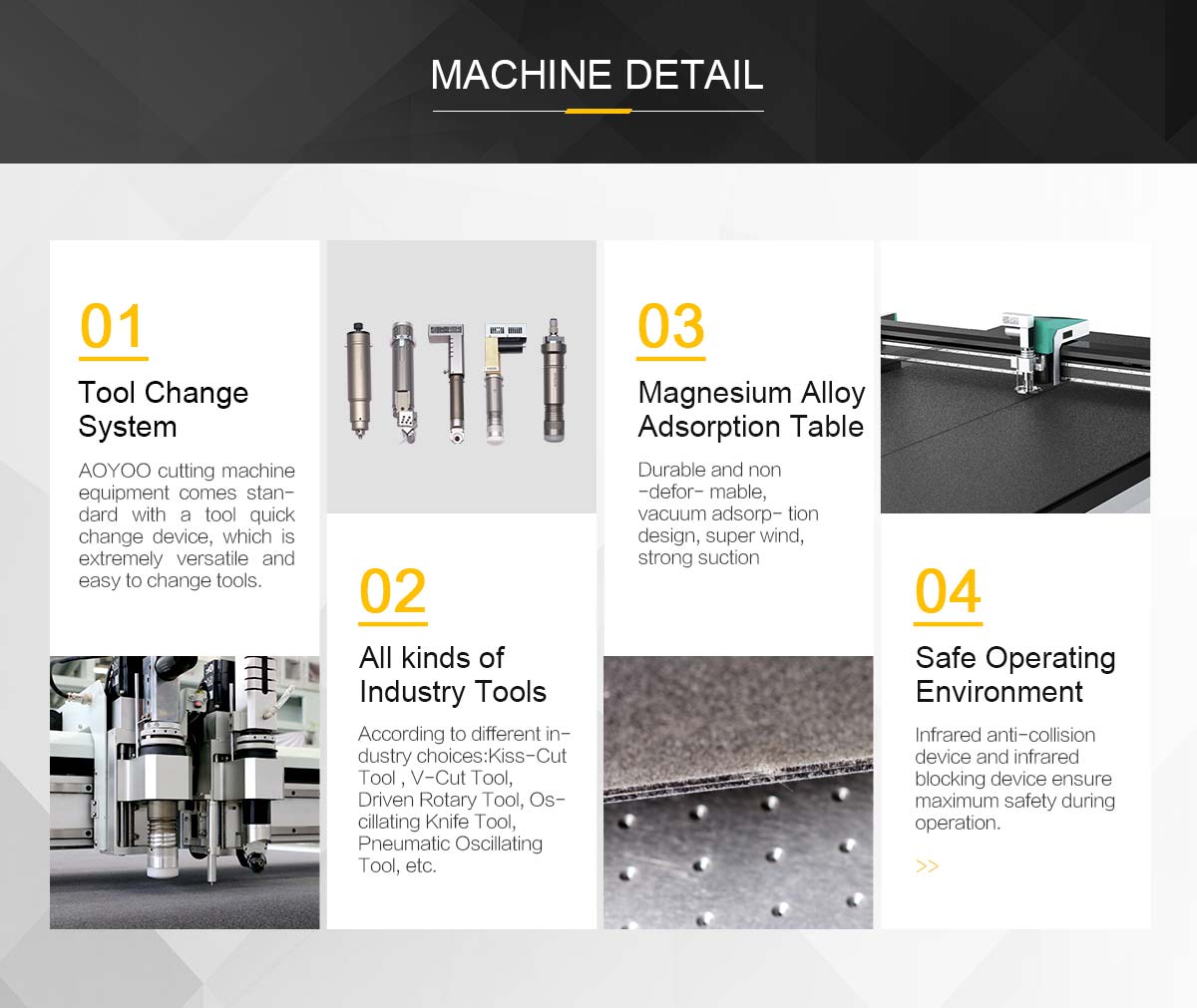

Multi-function tool | Vibrating knife full cutting, high power active round knife, punching tool, pneumatic knife, multi-layer knife | |||||

safety devices | Safety devices use infrared sensing, safe and reliable | |||||

Cutting speed | 200-2000mm/s | |||||

Cutting thickness | ≤50mm Other thicknesses can be customized according to the material | |||||

Material fixing method | Vacuum partition adsorption | |||||

Transmission port | Network port | |||||

Transmission system | Yaskawa servo motor, linear linear guide, timing belt, lead screw | |||||

rated power | 11kw | |||||

Rated voltage | 380V±10%/220V±10% Optional | |||||

Control System | Chinese and English LCD touch screen | |||||

Operating environment | Operating environment Temperature 0-40°C Humidity 20%-80%RH | |||||

Software | Automatic nesting software, template entry software(Optional) | |||||

Support file format | AI、PLT、DXF、CDRetc | |||||

Overall size | 3570x2290x1165mm | 3570x2500x1165mm | 3570x25800x1165mm | |||

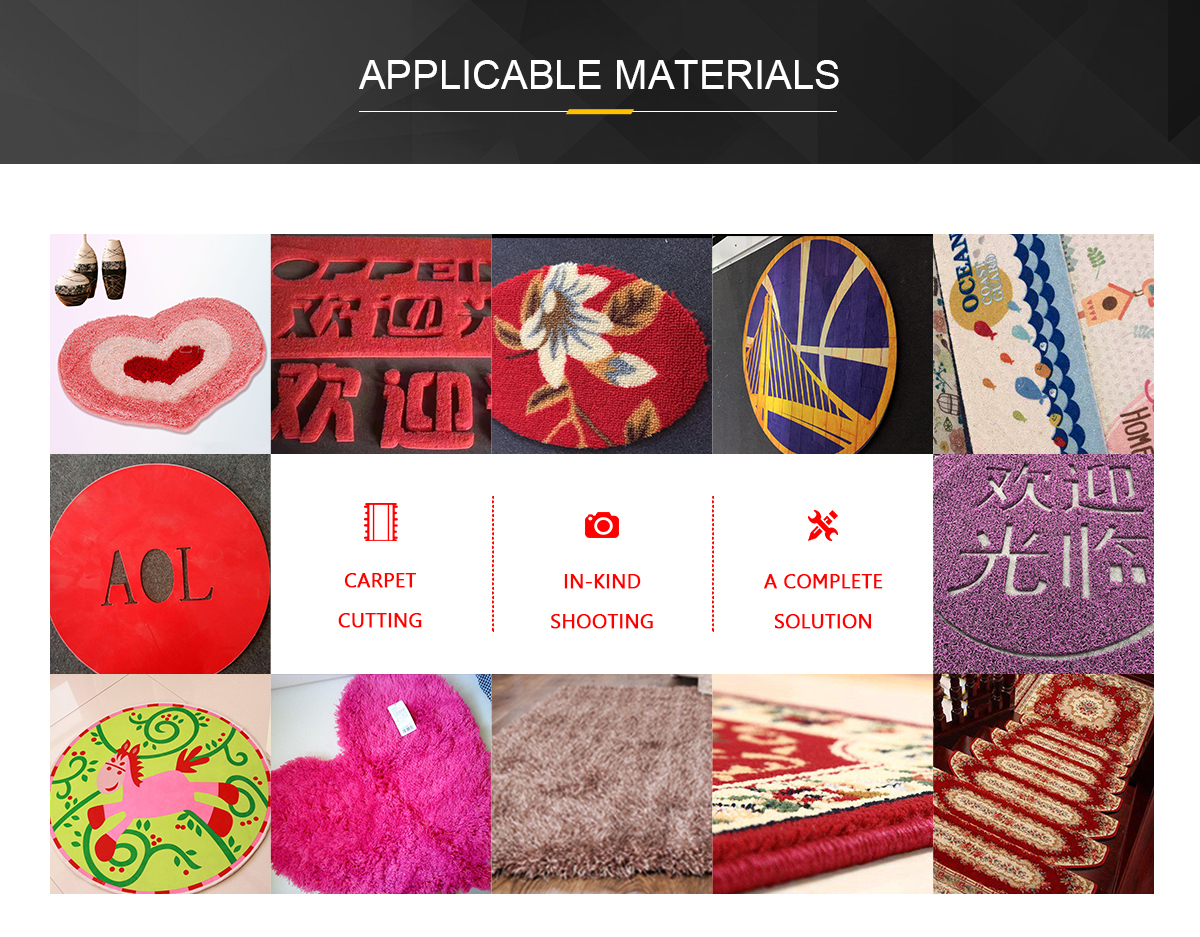

Applicable materials of carpet fabric shape cutting machine with automatic feeding Leather, fabric, textile, cardboard, plastic box, fiber glass,corrugated cardboard, sticker, film, foam boardrubber, cloth, gasket material, garment cloth, footwear material, bags materials, non-woven fabrics, carpets, sponge, PU, EVA, XPE, PVC, PP, PE, PTFE, ETFE and composites.

1. Cutting by knife not laser, no air pollution , no burnt edge, cutting speed is 5-8 times faster than laser cutting machine.

2. Imported square linear guide and Japanese servo motor ensure high precison and fast cutting speed.

3. The application of an Ethernet port makes the cutting plotters fast and convenient.

4. This cutting machine was designed easy to install, set-up and operate.

5. Special safety sensing device meets the European standard.

6. It can equipped with different tools to meet a variety of needs.

1. Outside package: Standard marine export plywood case.

2. Inner package: Stretchy film and plastic film for humidity.

We can package according to your requests.

Q1: I knew nothing about this machine, what kind of machine i should choose?

Very easy to choose. Just tell us what you want to do by using CNC cutting machine, then let us give you perfect solutions and suggestions.

Q2: When I got this machine, but I don’t know how to use it. What should I do?

We will send video and English manual with the machine. If you still have some doubts, we can talk by telephone or skype and e-mail.

Q3: If some problems happen to this machine during warranty period, what should I do?

We will supply free parts during machine warranty period if machine have some problems. While we also supply free life long after-sales service. So any doubts, just let us know, we will give you solutions.

Q4: Before sending me an inquiry on our cutting machine, it is better for you to provide me the following information

1)Your materials.

Colth/Lesther/Fabric/Rubber/Carpet/Corrugated box/Textiles?

2)You want to engrave or cut?

If cut, could you tell me your cutting thickness? Because different cutting thickness need different blade supplier.