ASSURANCE

The foam board CNC cutting machine with oscillating knifeis very suitable for cutting foam (EVA PVC) materials, the maximum thickness can be cut 50mm materials,The combination of the CNC cutting machine and the intelligent system forms a perfect cutting system, which can cut both flexible and non-ventilated materials. AOYOO series cutting machine is a model with excellent speed and precision. The head of the foam board digital cutting machine has two knife holders, which can be generally used to insert cutting knives, scoring tools or drawing pens to improve the function of the cutting machine.

| Technical parameters | AOYOO-6040 |

| Effective working area | 600*400mm |

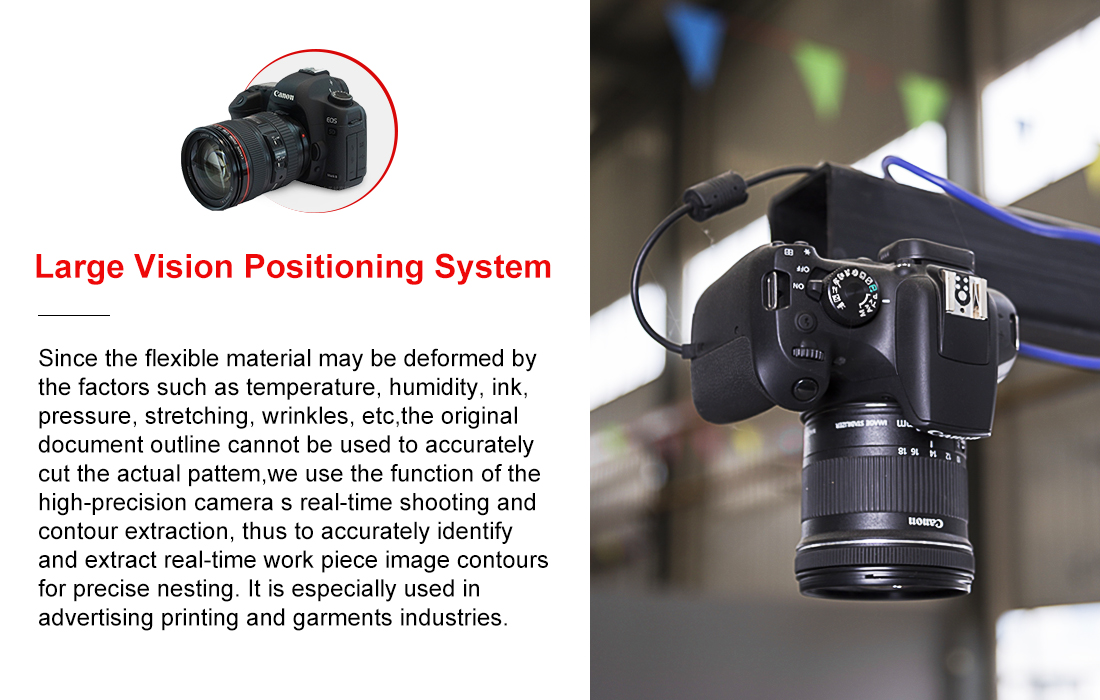

| Multi-function cutting head | The combination of Multi-function cutting head and holders, be with full cut, kisscut, creasing wheel,v-cut and laser red light positioning functions, CCD positioning, Camera extract large contour to cut |

| Tools | Oscillating knife, Milling tool, pneumatic knife, V-cut, crease wheel, kiss cut, drag knife |

| Overall size | 2420*970*1280mm L'W'H |

| Moving speed | 800-1500mm/s |

| Repeat precIsion | ±0.05mm |

| Interface | Enternet port |

| Control panel | LCD touch screen |

| Drive system | Imported servo motor, linear guid, synchronous belt, screw |

| Cutting material | Paperboard, grey board, KT board, pvc foam board, honeycomb board, car sticker, lamp piece, PP Adhesive material, printing cloth, banner cloth, all kinds of corrugated board, EPE foam, EVA, PVC board, acrylic board, thick foam and so on |

| Instruction system | HP- GL Compatible format |

| Rated power | 2. 2KW |

| Rated voltage | 220V |

| Cutting thickness | ≤50mm(According to different material) |

| Material fixed way | Vacuum adsorption |

| Auto feeding system | Acuum sucker adsorpting sheet |

1. High flexibility: The electric swing tool is very suitable for cutting EVA and PVC materials. With various blades, it is suitable for cutting materials of different hardness

2. High cutting accuracy: Imported high-precision racks are used to make the cutting of thick and hard packaging materials stronger and ensure higher cutting accuracy

3. Low-cost operation: equipped with tool quick-change module, independent research and development of tool quick-change device, realizing rapid replacement of more than ten kinds of tools. The cutting knife can be switched freely, which is suitable for various cardboard materials without changing the cardboard box cutting machine.

4. Durable and non-deformation: honeycomb aluminum workbench, vacuum adsorption design, super air, strong suction

5 Set up infrared induction anti-collision: to ensure the safety of personnel during operation

1. Super cost-effective-CNC intelligent cutting, creasing, drawing: cutting tools, creasing wheel tools, drawing pens, precision industrial cameras, and precision industrial camera vision positioning systems. A cutting machine can accommodate all your needs.

2. The vacuum suction cup on the beam has the function of separating the paper ejection nozzle in the paper feeding structure, thereby eliminating the paper adhesion caused by static electricity, fixing the material position, and ensuring the cutting accuracy.

1. Outer packing: standard seaborne export plywood box.

2. Inner packaging: stretchable film and plastic film to prevent moisture.

We can pack according to your requirements.

AOYOO has built its reputation on the superior turn around time we offer on both our quotations and packaging solution. With in house design capabilities, we can accommodate our customers’ every packaging needs including customised cardboard boxes. “No packaging solution is too hard, some just require a little more thought.” AOYOO can help you create innovative boxes and stands to protect and display your products.

If you are looking for foam board solutions contact us today! We are sure our competitive prices cannot be beaten.