ASSURANCE

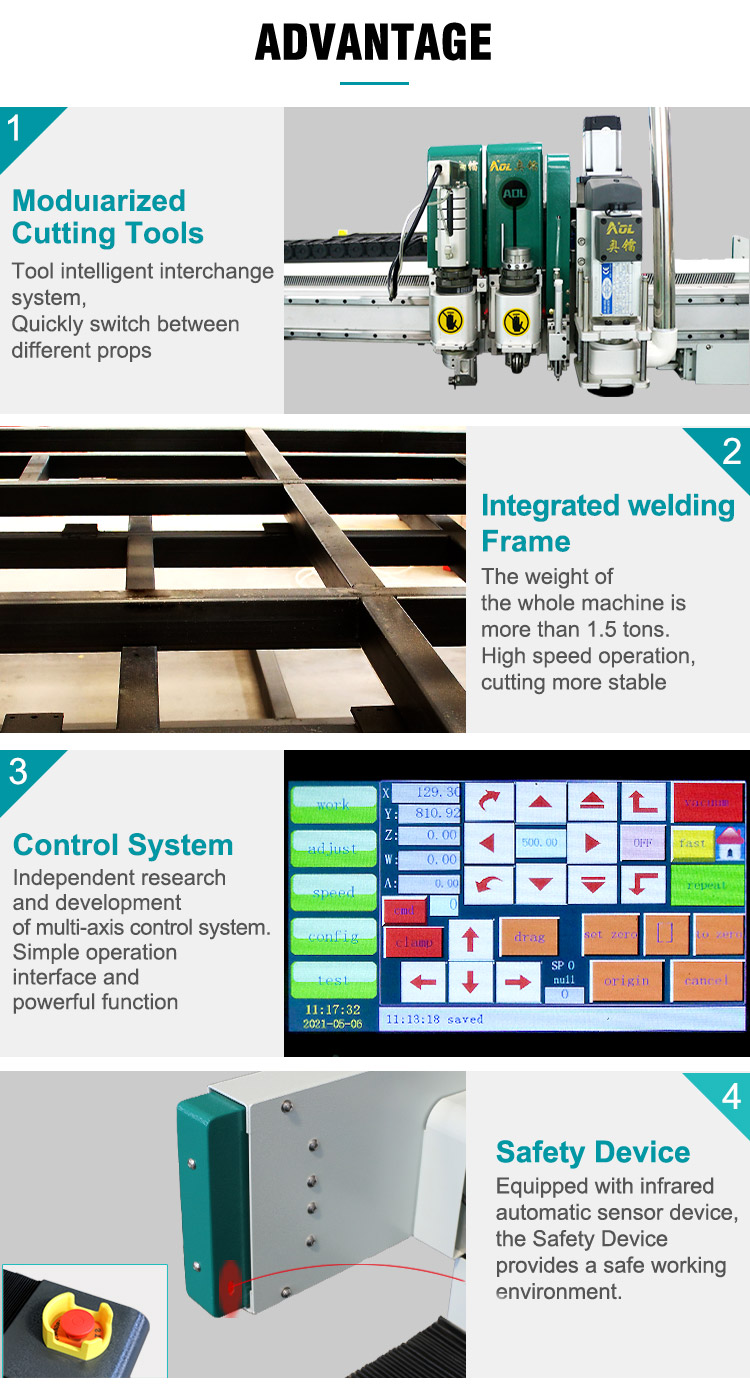

The foam plastic board cutting machine adopts integrated welding technology. The whole machine has undergone high temperature heat treatment technology to ensure that the equipment will not be deformed during long-term use. The working table is made of aviation alloy material, which is corrosion-resistant and friction-resistant. The inside of the alloy is a hollow material, which is mainly convenient. The vacuum adsorption system is installed, and the Austrian radium vacuum adsorption system adopts the follow-up adsorption system, which automatically moves with the cutting position, with strong adsorption capacity and more energy saving. Ao Lei foam plastic board cutting machine also adopts all imported electrical devices. Each electrical appliance has been tested for performance, and the hardware with low failure rate, long life and strong anti-interference ability is selected.

1. High efficiency, the equipment adopts imported servo motor, and the running speed can reach 2000mm/s.

2. Environmental protection, the equipment is cut with a blade, and the cutting process is smoke-free and environmentally friendly.

3. CNC system cutting to keep the cutting quality consistent.

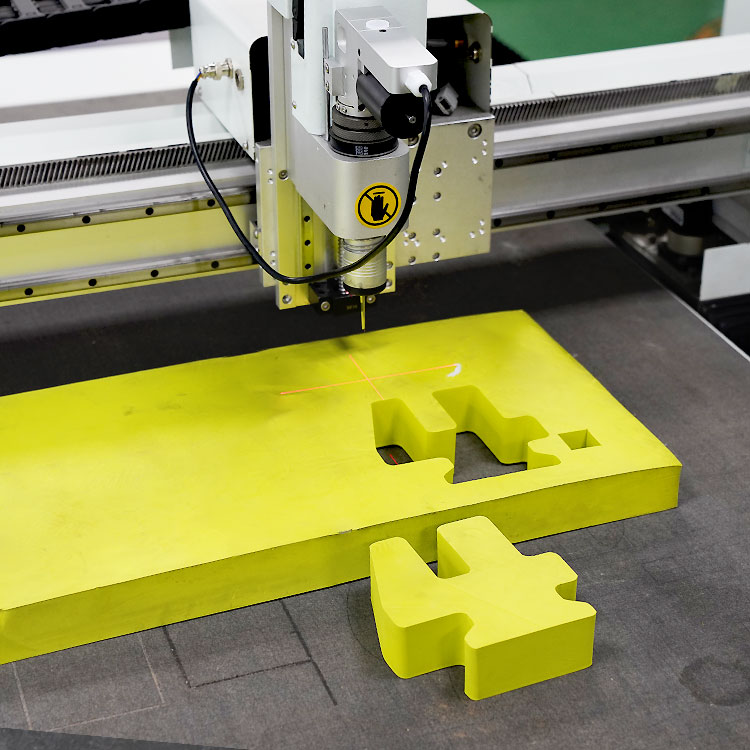

4. The cutting effect is good, the equipment supports cutting surfaces of any shape, the cutting edge has no burrs, the effect is good, and it can be used after the cutting is completed.

5. No need for molds, small batch orders are acceptable.

6. Strong applicability, the equipment has a variety of cutter heads such as round knives, vibrating knives, pneumatic knives, etc., using EVA, pearl cotton, foam plastic, EPE, leather, fabric, etc.

1. The cutting system independently developed by AOYOO is simple and easy to operate, has low technical requirements, and minimizes the cost of use by customers.

2. Using high-quality linear guide, the accuracy error is ±0.1mm.

3. Japan's Panasonic servo system provides power, stable and continuous power supply.

4. AOYOO CNC cutting machine is equipped with a variety of knives, which are used for material cutting in different industries and increase the added value of enterprises.

5. AOYOO foam plastic board cutting machine is fully automatic equipment, automatic loading and unloading, saving labor costs.

6. The system intelligently optimizes typesetting and cutting, provides better cutting and filling paths, and saves more than 30% of materials.

7. Power-saving variable frequency vacuum adsorption, saving power by more than 30%.

8. The infrared induction safety device ensures the safety of the operator during the high-speed movement of the machine, and at the same time avoids the loss of cutting materials

Learn more about the performance and catalogue of CNC cutting machine, click to leave a message, professionals will contact you!

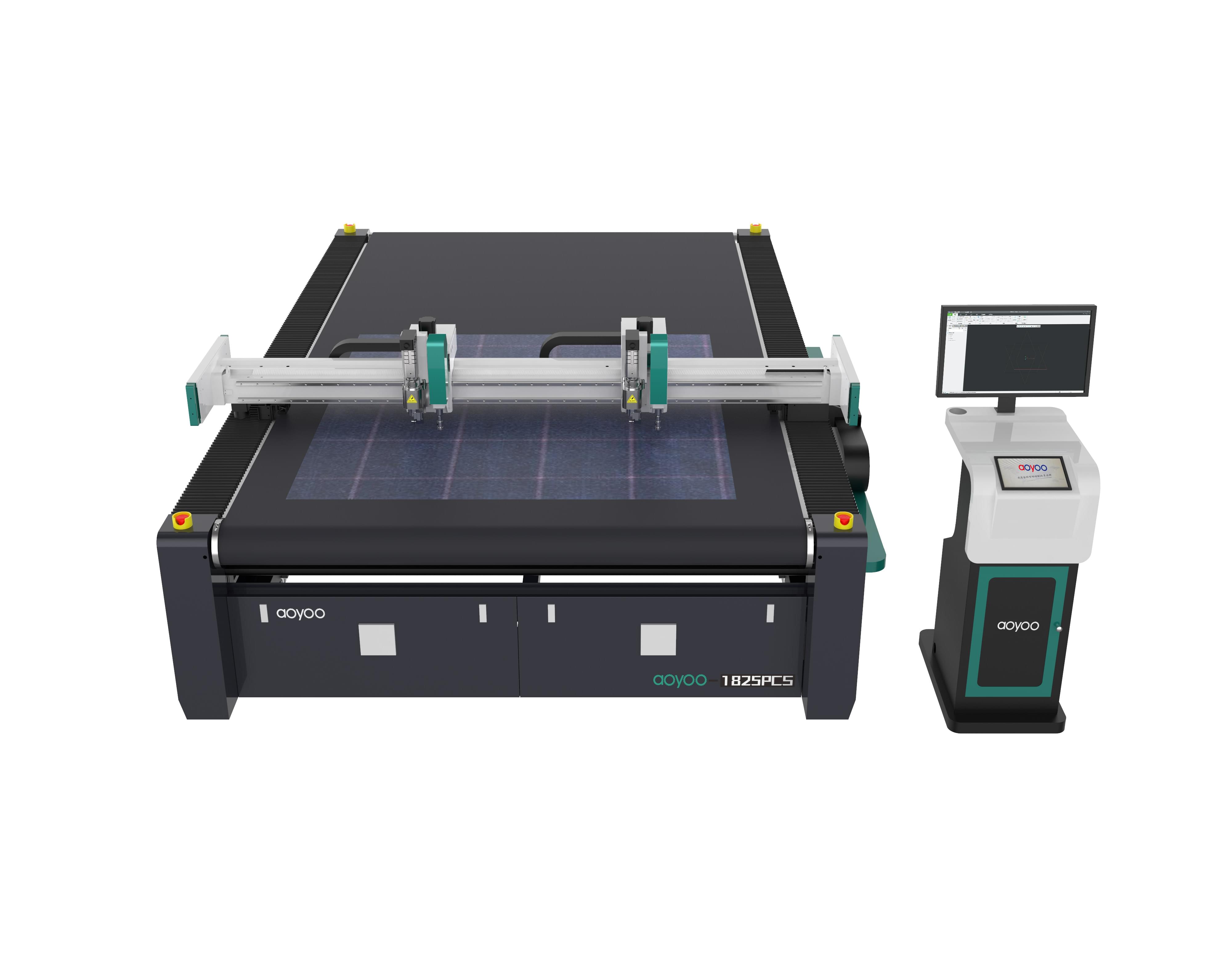

AOYOO foam plastic board cutting machine parameters

Technical parameters / model | AOYOO-1625-ZS6 | AOYOO-1825-ZS8 |

Effective working area | 1600x2500mm | 1800x2500mm |

Multi-function tool | Vibrating knife full cut, semi-cutting cut, indentation, drawing mark, cursor positioning, camera positioning edge cutting, high power active round knife | |

safety devices | Safety devices use infrared sensing, safe and reliable | |

Cutting speed | 200-2000mm/s | |

Cutting thickness | ≤50mm Other thicknesses can be customized according to the material | |

Applicable materials | Knitting, woven, fur (sheep shearing), PU leather, oxford cloth, canvas, sponge, imitation leather, cotton linen, blended fabric etc. All kinds of clothing, bags, sofa fabrics and carpet fabric etc | |

Material fixing method | Vacuum partition adsorption | |

Transmission port | Network port | |

Transmission system | The X\Y axis is divided into two kinds of rack or belt | |

rated power | 11kw | |

Rated voltage | 380V±10%/220V±10% Optional | |

Control System | Chinese and English LCD touch screen | |

Operating environment | Operating environment Temperature 0-40°C Humidity 20%-80%RH | |

Support file format | AI、PLT、DXF、CDRetc | |

Overall size | 3570x2290x1165mm | 3570x2500x1165mm |

1) Three-year free warranty (except vulnerable parts), free inspection and maintenance of main components.

2) Provide lifetime free technology upgrade service

3) Wearable parts (such as blades, workbench covers) are always available at cost when needed.

4) Free operation training is conducted in our factory. If there is not enough time, we will send detailed training videos.

5) 24-hour online service, providing free technical support in different languages.

6) On-site technical support can be provided when needed.

AOYOO is an industry-leading brand with 14 years of experience in the industry. We have served more than 8,000 customers worldwide and received satisfactory evaluations. We have many customers who have been cooperating with long-term and stable cooperation. We provide many customers with In order to provide a personalized industry material cutting solution, if you encounter problems with industry material cutting, we can provide you with free consultation and advice services!

E-mail:info@aolcnc.com

phone:+86-18560162709

WhatsApp /Wechat:+8618560162709

youtube:https://www.youtube.com/channel/UCctbMXFvompG-41Wecb1mpw

website:https://www.aoyoocut.com/

Facebook:https://www.facebook.com/AOYOOCUTTER