ASSURANCE

Clothing has been inseparable from people's lives since it was created. With the continuous improvement of people's requirements for material life, the types of clothing fabrics are also constantly changing. renew.

When the types of clothing fabrics continue to increase, the market has higher and higher requirements for cutting finished products. According to our understanding and investigation of the market, the main problems faced by garment processing factories are the following 7 points:

1. Manual typesetting, serious waste of materials and increased cost;

2. The cutting efficiency is low, the output in the peak season cannot increase, and the order delay is overtime;

3. Poor cutting accuracy, easy deformation of clothing fabrics, cutting errors, easy to lose customers;

4. The printing fabric is customized, the process is cumbersome, and the labor is time-consuming;

5. In the face of special fabric cutting, the edges are not neat and the cutting quality is poor;

6. Small batch orders, frequent and complicated board making, and many types are difficult to manage;

7. The cost of recruitment is high, the salary of professional tailors is high, the off-peak season is obvious, and it is difficult to recruit.

In fact, for garment processing factories, it is obviously not feasible to simply use "finished product processing" to earn fees and operate factories. Especially in today's rising labor costs, the survival rate is very low in factories that still use labor as the main productivity. This is also the reason why the factory adopts intelligent clothing cutting machine to achieve "intelligence and mechanization".

In the intelligent mechanical cutting equipment, the traditional production process is abandoned online, and the automation and intelligence of all links are incorporated into the equipment design to achieve more coordinated and efficient production.

Intelligent typesetting, efficient cutting, software intelligent compensation, automatic loading and unloading... effectively help factories flexibly produce diversified products and quickly respond to more market changes.

Now that the times are constantly developing, we must recognize a reality - the possibility of returning to the era of low-cost processing is extremely low.

Therefore, the emergence of clothing intelligent cutting machine is not only a trend of the times, but also a conservative means of survival of the fittest in the market. What we can do is to continuously improve our competitiveness, continue to survive and develop healthily.

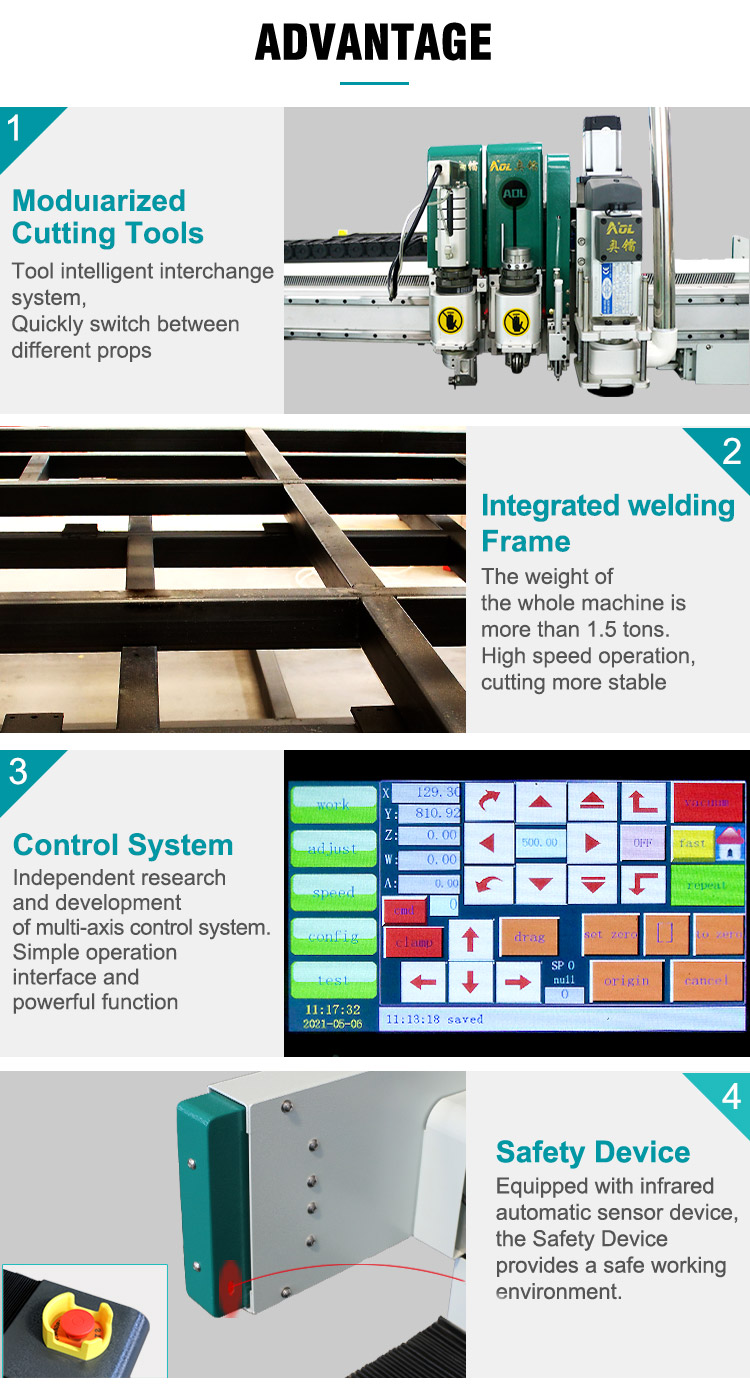

1. AOLCUT self-developed software can be imported with one key, and ordinary workers can be proficient in 2 hours

2. The software and material utilization rate of Super Nesting Master has been increased by more than 10%

3. Select Taiwan linear guide drive system, with an accuracy of ±0.1mm

4. Using Japanese Panasonic servo system, the production efficiency is increased by more than five times

5. AOL's unique tool exchange system, automatic completion of cutting, punching and marking

6. Automatic material pulling, automatic material receiving, saving time and effort

7. The annual saving of labor and raw materials is more than 500,000, which greatly improves the competitiveness of products

Due to the continuous expansion of market demand, the factory is paying more and more attention to the development of the garment industry. If you want to know more about the cutting machine in the garment industry, please contact us!