ASSURANCE

The most important step in shoe upper processing has always been cutting. There are many materials for shoes, such as leather, leather, and fabric. In the past, due to the processing technology, the upper cutting was mostly manual cutting, and some manufacturers would use punch cutting. What is the effect of cutting? With the development of the economy, it is more and more difficult to recruit factories, and the labor is not enough to meet the needs of production.

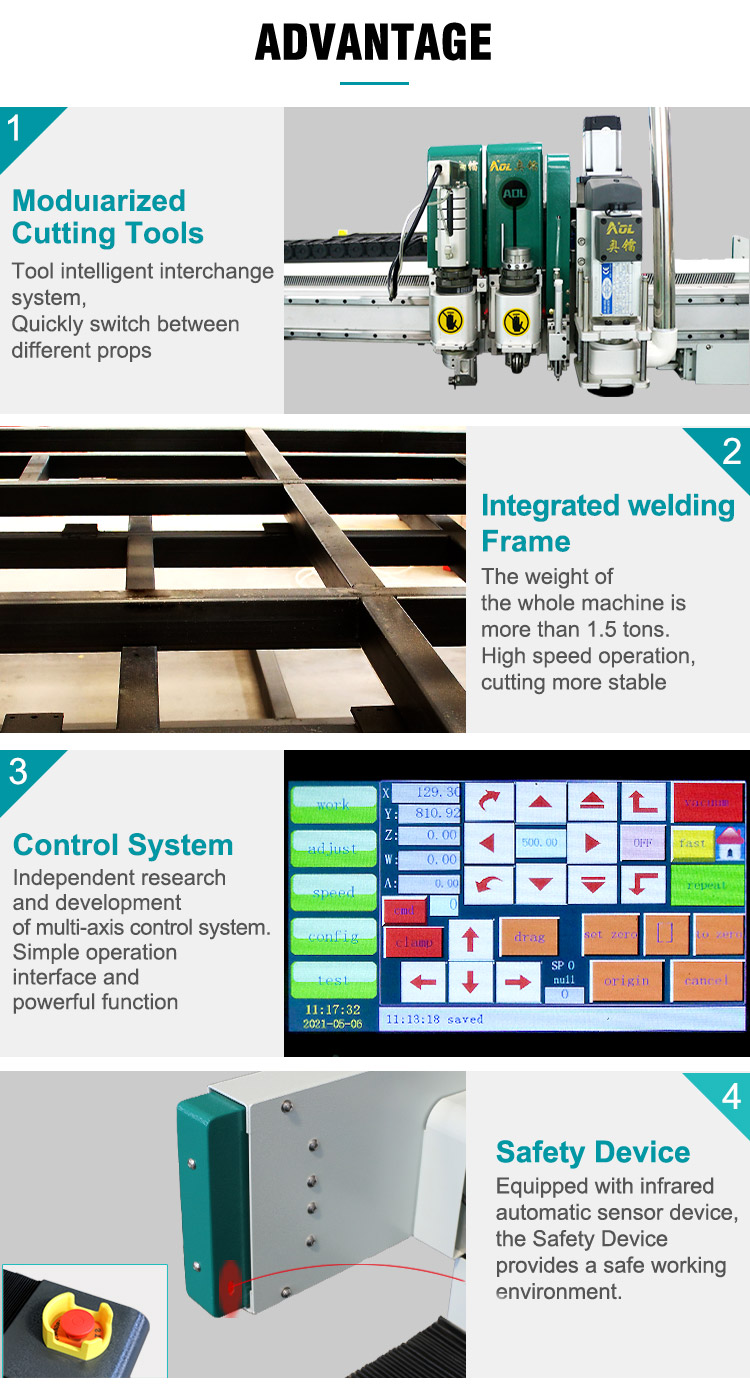

Under this pressure, AOL developed a vibrating knife vamp cutting machine to help small and medium-sized manufacturers solve production problems. The vamp vibrating knife cutting machine integrates automatic feeding, cutting, punching and cutting into one device. Replacing 4-6 laborers, high cutting efficiency and good cutting effect.

The equipment adopts a self-developed system, which is very simple to operate. For imitation leather cutting, the material is now placed on the feeding rack, and the computer typesetting system is activated. After the computer is automatically typesetting, it can realize automatic cutting. The whole process can be completed by one person alone . Compared with imitation leather, leather cutting has an automatic extraction contour to identify defect cutting. The whole process is digital cutting, which realizes the calculation of material utilization rate and realizes production control to a greater extent.

The vibrating knife upper cutting machine adopts an integrated square tube welding body, the wall thickness of the square tube is 4-6mm thick, and the high temperature quenching treatment ensures that the equipment will not be deformed during long-term operation, and always maintain high precision. and durability are higher than domestic products. The equipment and electrical appliances are of the Omron brand. After tens of millions of experiments, the failure rate is low and the service life is long.

The shoe upper cutting machine is a milestone in the history of cutting development. It promotes the transformation of the cutting business to digitalization, allowing more manufacturers to achieve controllable production, and the cutting machine has the function of saving materials, helping enterprises save a lot of costs and achieve cost reduction and efficiency.

If you want to know more about performance issues, please leave a message , we will have a professional staff contact you.