ASSURANCE

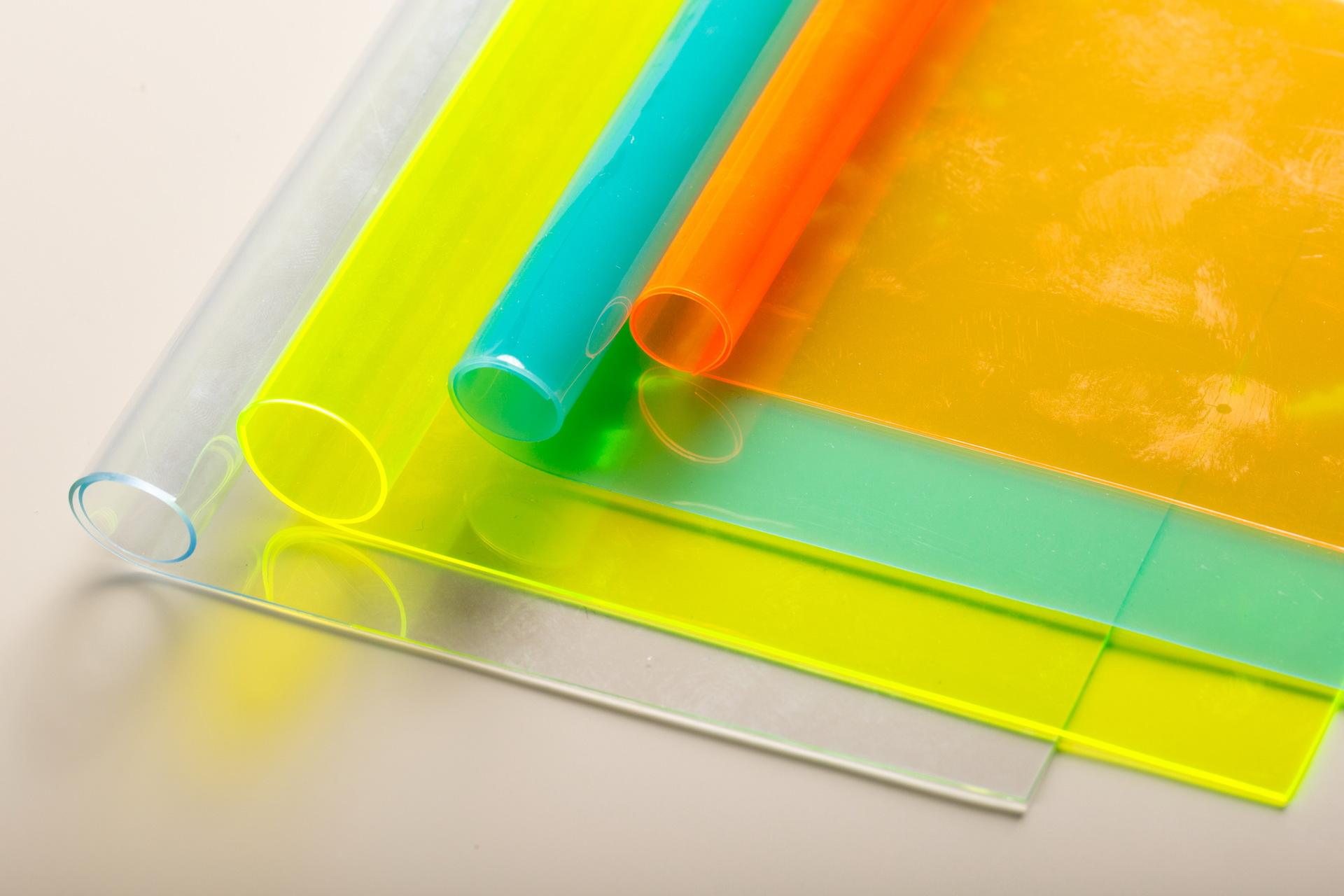

Soft glass, also known as PVC soft crystal plate, has industrial use or household use respectively. Smooth surface, no cracks, no bubbles, uniform color, heat resistance, cold resistance, aging resistance, heavy pressure resistance, strong acid and alkali resistance, good light transmission, long service life.

Usually we often see that the table is covered with transparent soft glass, and there are certain requirements for the cutting of this type of material. Recently, we have received a lot of inquiries about PVC soft glass cutting machines. Ask our cutting machine Is it possible to cut their material? Questions such as efficiency, etc., I will explain them in detail today with these questions!

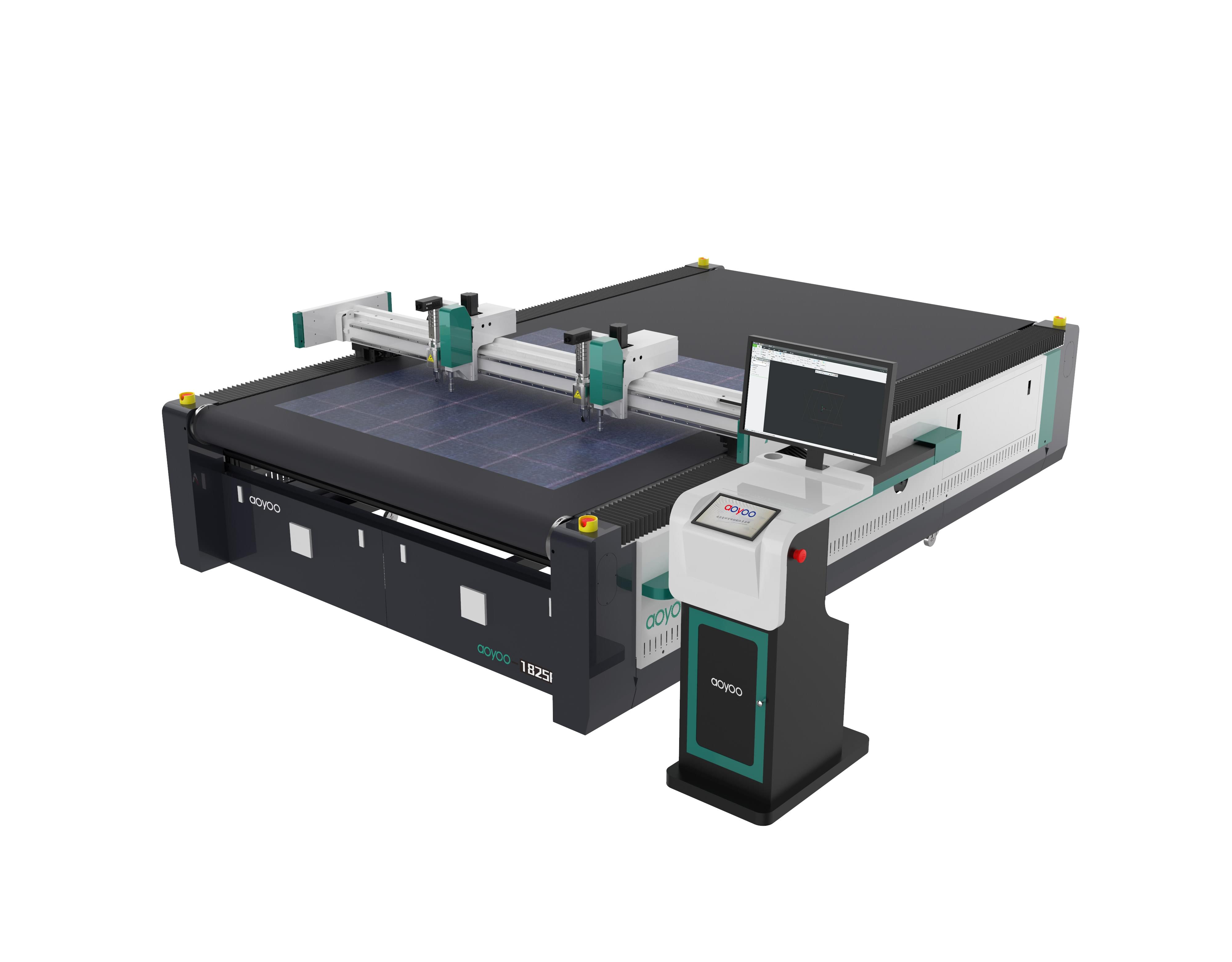

1. Independently develop and design CAM software, intelligent software compensates, optimizes the cutting path, and improves production energy efficiency.

2. Using high-quality linear guide, the accuracy error is ±0.1mm.

3. The system intelligently optimizes typesetting and cutting, provides better cutting and filling paths, and saves more than 30% of materials.

4. The whole machine is equipped with anti-static system to protect the safety of personnel to the greatest extent.

5. Anti-static interference and soft start device to protect the safety and stability of the equipment.

6. Professional R&D team can provide assembly line supporting solutions

1. When the PVC soft glass cutting machine is energized or running, please do not touch any electronic components in the electrical cabinet and the console, which is easy to send electric shock to the scene.

2. Please do not operate the switch button of any PVC soft glass cutting machine with wet hands to prevent electric shock.

3. Please do not check the wires or replace the electronic components with electricity, because it is easy to cause electric shock or injury.

In order to improve the service life of the PVC soft glass cutting machine, it is generally recommended to place the PVC soft glass cutting machine in a place without direct sunlight or other heat radiation, and avoid places that are too humid, dusty or corrosive gas, because these The environment is easy to damage the electronic components of the PVC soft glass cutting machine, or cause poor contact and short circuit between components, thus affecting the normal operation of the equipment. Of course, the correct operation is also one of the important measures to ensure the normal operation of the PVC soft glass cutting machine. The operator must operate according to the instructions or the methods taught by the engineer. If the equipment fails, the operator needs to pay attention to keeping the site, and online or It is the engineer who goes to the door for maintenance to explain the situation before and after the failure in detail, so as to facilitate the analysis and diagnosis of the cause of the failure, and eliminate it in time, so that the equipment can run normally.

1) Three-year free warranty (except wearing parts), free inspection and maintenance of main parts.

2) Provide lifetime free technology upgrade service

3) Wearable parts (eg blades, bench covers) are always available at cost when needed.

4) Free operation training in our factory. If there is not enough time, we will send detailed training videos.

5) 24-hour online service, providing free technical support in different languages.

6) On-site technical support is available when needed.

7) AOYOO accepts unreasonable returns within 7 days after receiving the goods.

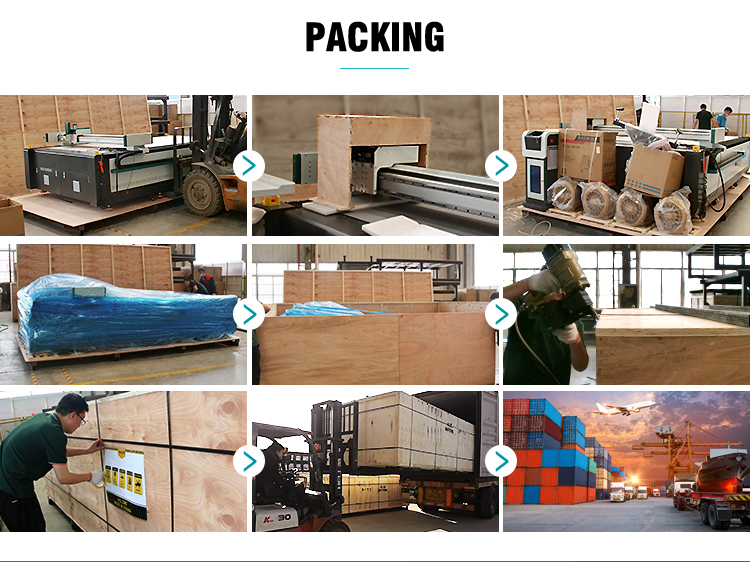

1. Outer packing: Standard sea export plywood box.

2. Inner packaging: stretchable film and plastic film to prevent moisture.

If you have special requirements, we can negotiate amicably

E-mail:info@aolcnc.com

phone:+86-18560162709

WhatsApp/Wechat:+8618560162709

YouTube:https://www.youtube.com/channel/UCctbMXFvompG-41Wecb1mpw

website:https://www.aoyoocut.com/

Facebook:https://www.facebook.com/AOYOOCUTTER