ASSURANCE

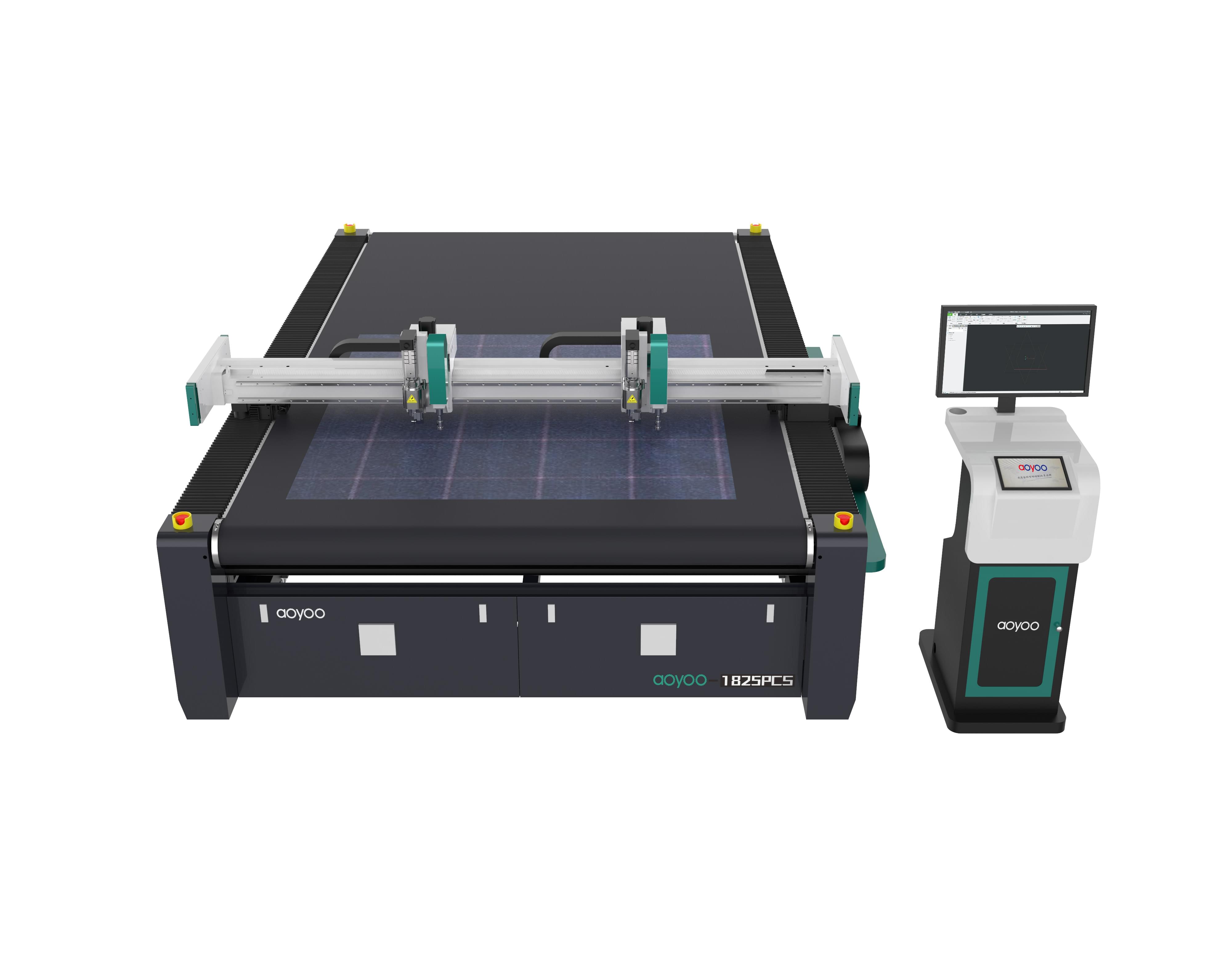

With the continuous advancement of modern technology, the CNC cutting machine industry has also made great progress in technology. Therefore, CNC cutting can be used more efficiently and can save material greatly. Because of this, we will introduce to you today how to use CNC cutting machine efficiently to avoid material waste.

The most important criteria for an enterprise to judge the quality of CNC cutting machines are cutting efficiency and cutting quality. Under the same machine tool structure, production level, and the configuration of key components are basically the same or similar, the cutting efficiency and cutting quality are determined by the optimized nesting software and the cutting control software of the CNC system. Therefore, to improve the cutting efficiency and cutting quality, Realizing full-time cutting, automatic cutting, high-efficiency cutting, high-quality cutting and high nesting rate cutting can only be achieved by optimizing nesting software and CNC cutting control software and the improvement of automatic punching and automatic cutting processes.

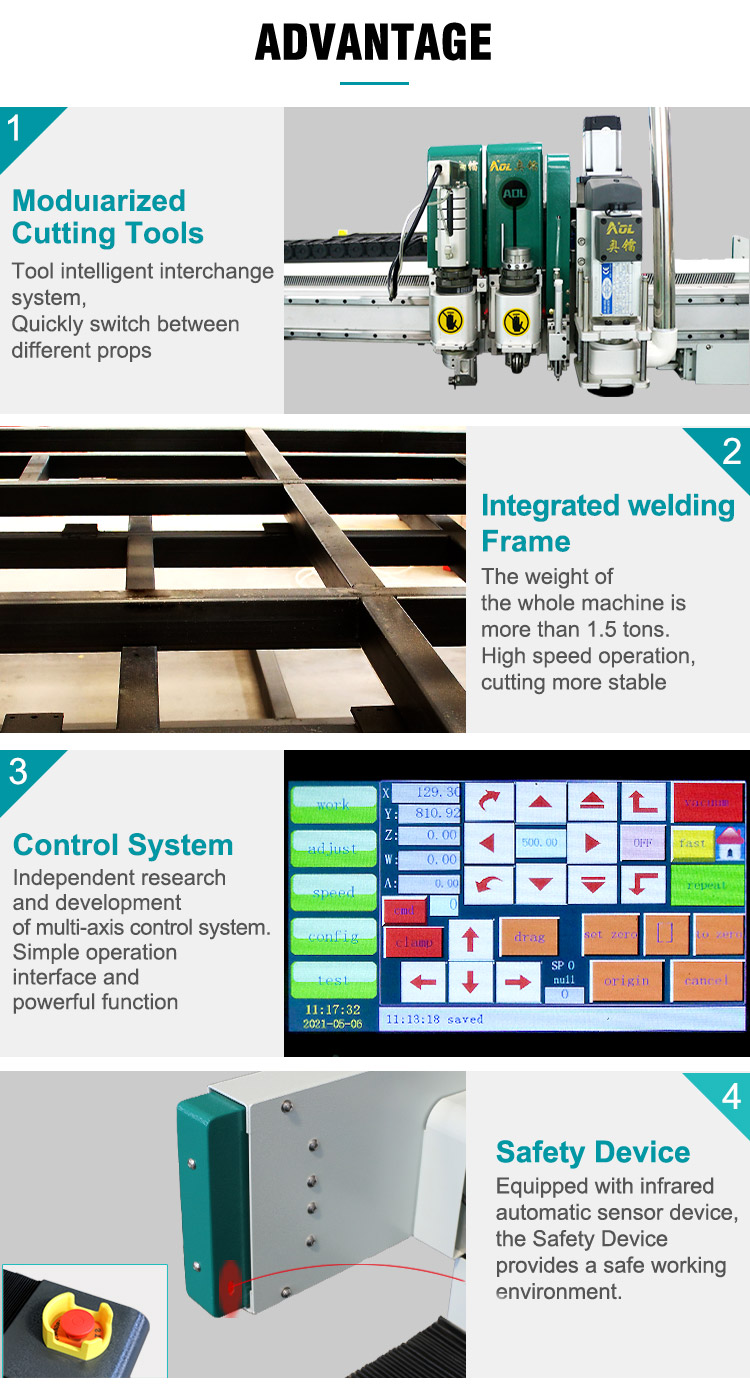

In the past, when cutting with a CNC cutting machine, it took half the time to wait for the response of the program. Now, after the update, the special nesting software can be used to directly arrange the material, which is beneficial to improve production efficiency. The appearance of CNC cutting machine replaced the original manual manual cutting method. The system intelligently optimizes the typesetting and cutting functions, which can provide better cutting and filling paths and save materials by more than 30%. Moreover, the machine has an infrared sensor safety device, which can ensure the safety of the staff to the greatest extent in the process of ensuring the normal operation of the machine.

If there is anything else you want to know or if you have any questions about the above, please contact usand we will answer you as soon as possible!