ASSURANCE

Corrugated cardboard is one of the most common packaging in the packaging industry. Therefore, the demand for corrugated cardboard is very large worldwide. Corrugated cardboard has different hardness, and the cutting of corrugated cardboard also has different quality levels. Corrugated cardboard changes from raw materials to A packaging carton not only needs to be cut, but also corrugated cardboard needs to be coordinated with multiple processes. Let's take a look at how to cut corrugated cardboard.

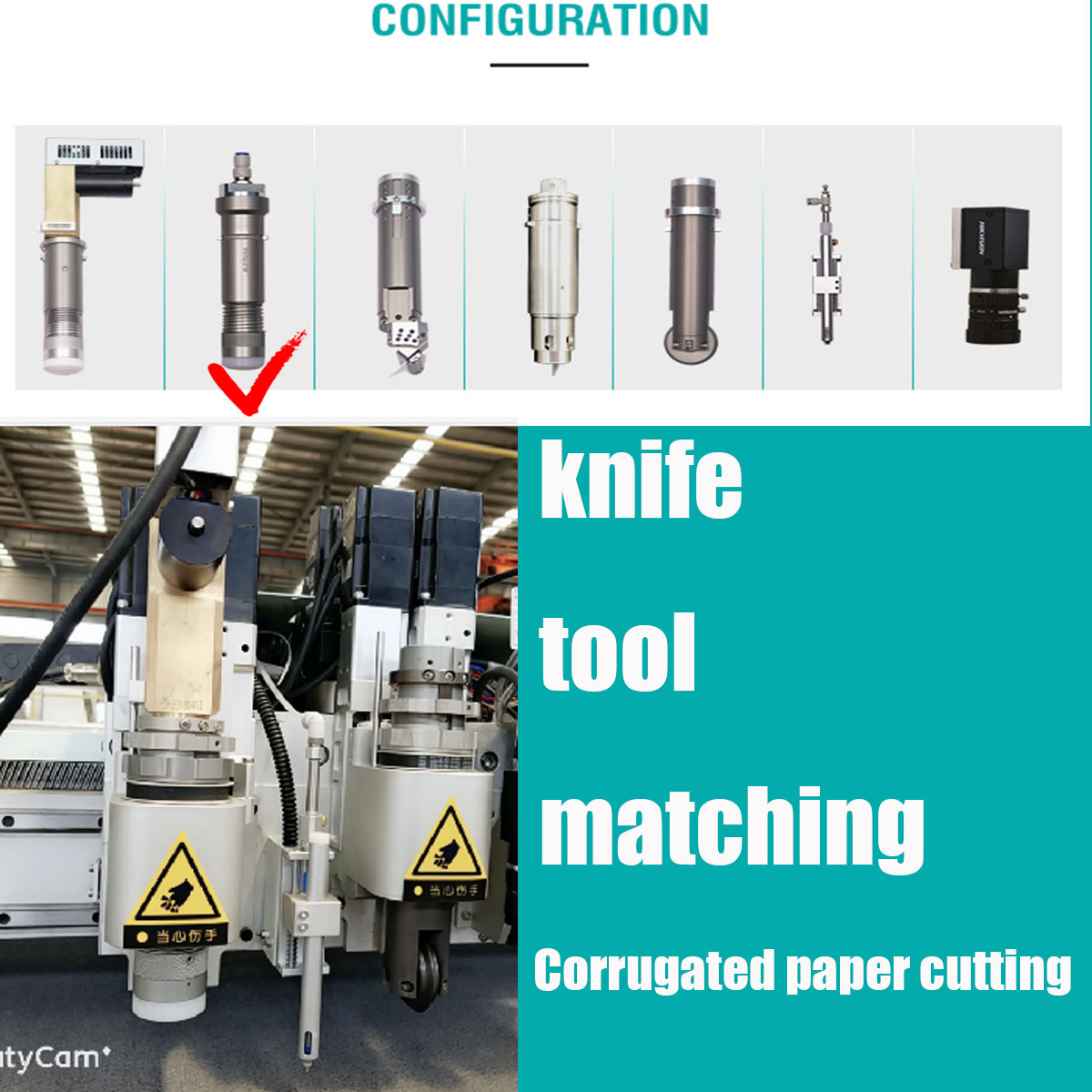

This time we understand the cutting of corrugated cardboard. The cutting machine we chose is the AOYOO 1625PA machine. This machine uses a physical cutting method and does not pollute the environment. The cutting edge is smooth and the material utilization rate is compared with other machines. High, so we use this CNC cutting machine to show the cutting process.

1. Material: Determine the thickness of the corrugated board material to be cut, so as to facilitate the selection of the appropriate CNC cutting machine cutting tool.

2. Selection: Choose the blades and auxiliary tools needed for corrugated paper cutting, and the size of the tools. It is recommended to use a round knife for cutting, and the pressure wheel to choose indentation.

3. Placement: Place the selected tool into the tool holder, adjust the depth of the tool and the parameters of auxiliary tools.

4. Debug: check whether the machine is working normally (panel click test).

5. Data import: the machine works normally, import data to the computer.

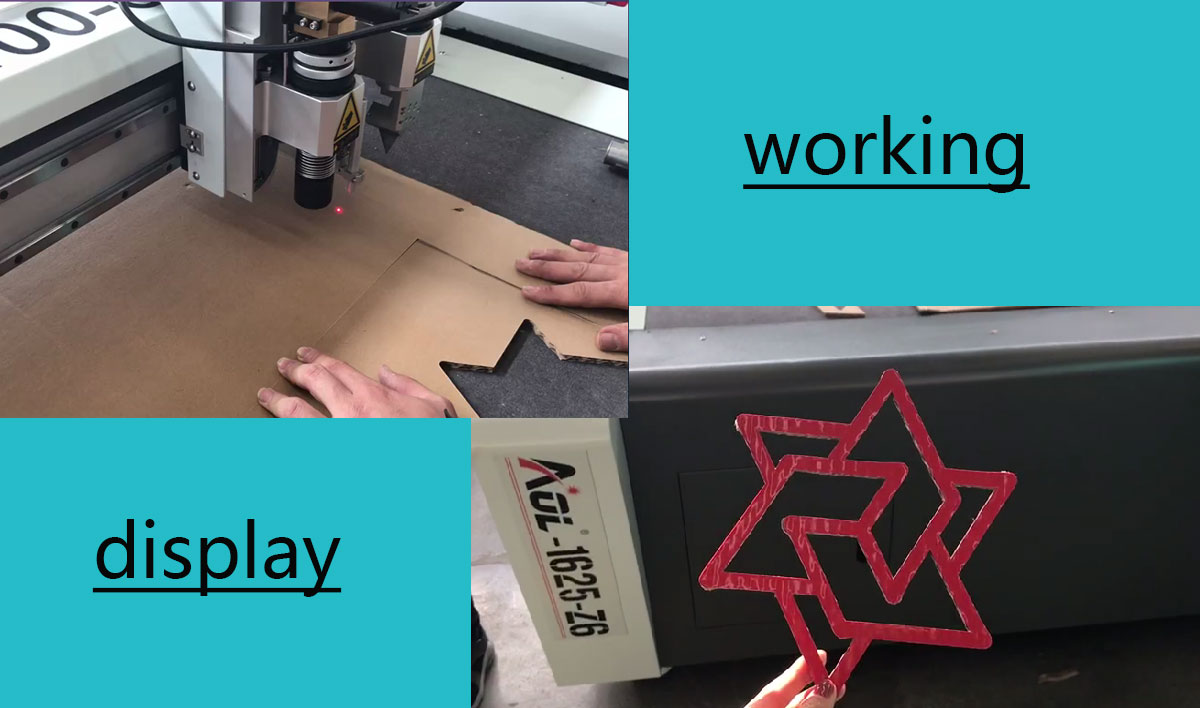

6. Start working.

The machine is designed for automatic correction, no data refresh is required.

Corrugated paper cut completed

Finished product display