ASSURANCE

Well known ,Glass fiber products have good performance and wide applications, and are a rising industry worldwide: glass fiber (referred to as glass fiber) is a new type of inorganic non-metallic material with superior performance, and it is also the most widely used composite material in modern industry. Glass fibers are classified according to their composition and can be divided into non-alkali glass fibers, medium-alkali glass fibers, and high-alkali glass fibers.

Glass fiber material as a basic material has the characteristics of a high degree of relevance to downstream production. The glass fiber is deeply processed and has a wide range of applications, such as: building materials, transportation, electronic appliances, environmentally friendly wind power, etc. The glass fiber industry has close relations with upstream and downstream enterprises. Committed to the practical application of automated cutting of composite materials, it has been practically applied in many professional fields such as sports equipment, automobile manufacturing, aerospace, yachts, teaching, green energy, communication equipment, etc., and has formed a complete prep-reg, glass fiber, carbon fiber , Unsaturated polyester, epoxy, phenolic, vinyl ester, felt and fabric, aramid fiber, thick foam and other composite materials automatic cutting program.

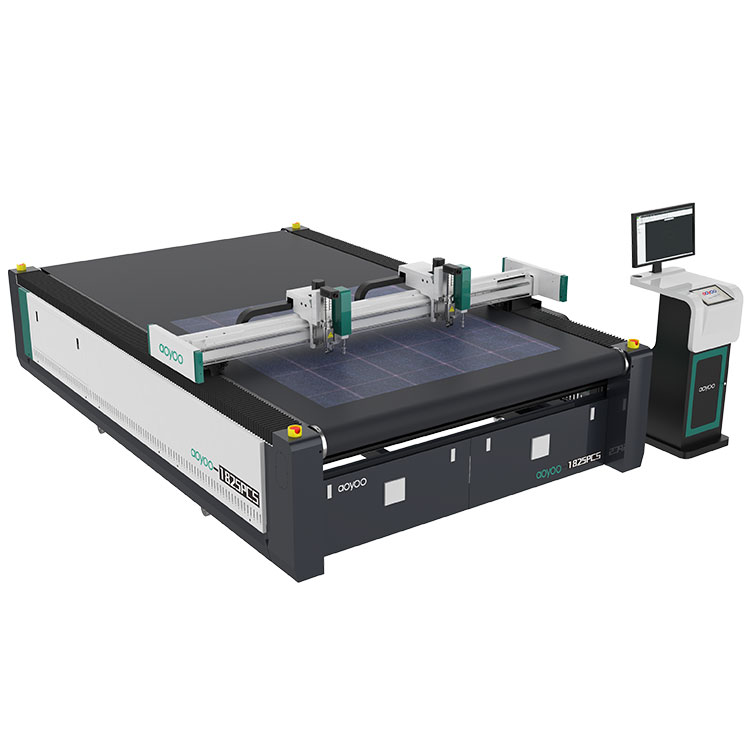

Compared with traditional die punching and CO2 laser cutting, the CNC knife cutting machine does not require a die, saves time and effort. It has precise sample cutting, smooth edges, no saw-tooth, no yellowing and scorching, no dust, dust, odor, and more environmentally friendly. The features of convenient maintenance and low use cost greatly shorten the development cycle of user styles and solve the problem of difficult production and processing of small batch orders.

Compared with traditional die punching and CO2 laser cutting, the CNC knife cutting machine does not require a die, saves time and effort. It has precise sample cutting, smooth edges, no saw-tooth, no yellowing and scorching, no dust, dust, odor, and more environmentally friendly. The features of convenient maintenance and low use cost greatly shorten the development cycle of user styles and solve the problem of difficult production and processing of small batch orders.

1. Digital toolless production, one-time, accurate visual production, saving tooling or labor costs, $16000/each year.

2. Reduce error rate, accurate and stable performance: not affected by employee emotions, reduce invisible consumption, 4-5 times higher than manual efficiency and increase material usage rate by about 5%

3. Precision cast steel pipe structure, military-grade components, international leading control software, service life up to more than 10 years

4. AOL is committed to brand building and enhance corporate competitiveness

5. Convenient and quick detail processing: arbitrarily adjust the depth of the knife, complete cutting, scribing, drawing, and labeling. The integrated processing is completed.

6. Quickly complete the diversified production of small and medium batches to meet the small orders of large customers

7. Machine maintenance costs: This is also very important. Because the cost of mechanical equipment in the middle of the use process is still very large, then it is necessary to do the necessary maintenance at this time, and to do the inspection on time to reduce a lot of unnecessary damage.

8. Machine brand: In fact, it is the result of applying the cutting machine to the leather industry. Because of the extensive use of the leather industry, machinery and equipment manufacturers must constantly improve according to the specific needs of the leather industry, so in the selection process, the product performance and after-sales service are better.

9. What you think is what you get, easy to learn, understand and operate

So now let us follow the pace of international advanced cutting technology together !Do you know the theories and viewpoints of the above-mentioned real vibrating knife cutting machines? We believe this article will help you better choose a cutting machine in this industry to meet your material needs !

Related Products: Carbon Fiber Prepreg Cutting Machine

For more information about glass fiber cutting machine, please click to leave a message, and timely feedback from professionals.