ASSURANCE

Fluoroplastic is a high-performance, multi-purpose new type of composite material, which is based on high-temperature and high-strength glass fiber cloth, which is compounded by fluororubber through a special process. The fluorine rubber fiberglass composite cloth cutting machine is a revolution in the cutting machine industry. It combines complex cutting procedures into a set of intelligent cutting system, which saves labor and material costs for material cutting manufacturers and enhances product competitiveness. Fluorine rubber fiberglass composite cloth cutting machine is suitable for a variety of materials, such as leather, fur, clothing, carpets, composite materials, gaskets, etc. The cutting thickness varies from 0.05mm to 50mm, and some low-hardness materials such as pearl cotton can be cut .

The temperature resistance of fluororubber cloth is the best among polymer composite elastomer materials at present. Its unique high temperature resistance can reach 300 ℃, which makes it resistant to various lubricating oils, fuel oils, compressed oils, etc. under high temperature conditions. . And it has the characteristics of resistance to ozone, oxygen, light and weather aging, acid and alkali resistance and resistance to various chemicals, and has excellent weather resistance in field use. It has been widely used in aerospace, aero-engines, chemical plant equipment, electrical power plants and other fields, as well as in the belt design of desulfurization and denitrification. It is an irreplaceable high-tech composite material.

Lay the material flat on the cutting table, input the pattern you want to cut with the computer, set the position and size of the material to be automatically positioned, the computer automatically typeset, and one-click cutting is satisfactory. Our machine is also equipped with an automatic loading and unloading device, which is easy to operate throughout the process. The coiled material can be automatically fed with automatic typesetting and cutting. In addition, the machine also has automatic edge-finding and cutting, which is convenient and saves labor costs.

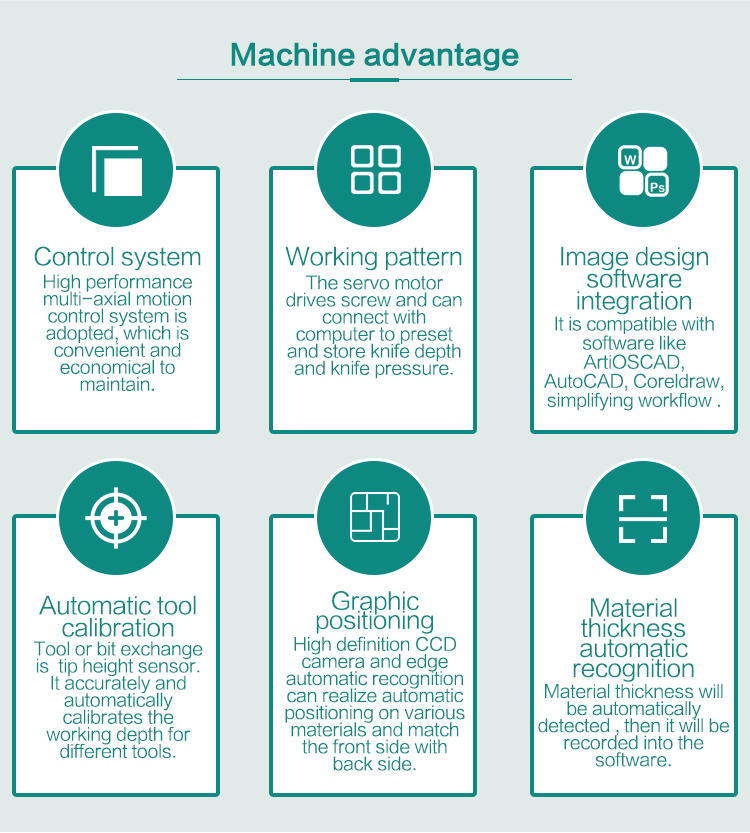

1. The table compensation function is used to detect the flatness of the table through a high-precision distance detector, and to correct the plane in real time through the software to achieve a perfect cutting effect.

2. Overcut optimization function, using self-developed CAM software to systematically optimize the physical overcut phenomenon of the tool, restore the graphic outline to the greatest extent, and bring customers the perfect cutting effect.

3. Automatic tool setting function, fast and simple automatic tool setting system, using sensors to accurately detect the tool, greatly improving the tool setting efficiency

4. Vacuum adsorption function, super strong wind, strong suction, the size of the vacuum adsorption area can be selected, and the power consumption can be greatly reduced

5. High-definition CCD camera realizes automatic positioning and sleeve cutting of various materials, eliminating the problems of inaccurate manual positioning and printing deformation.

6. Double-head automatic switching, the cutting process realizes double-head automatic switching, to meet the needs of different processing technology of materials

1. One-click import of self-developed software, ordinary workers can work skillfully within 2 hours

2. Adopt Taiwan linear guide drive system, the accuracy is ±0.1mm

3. Super nesting software, the material utilization rate is increased by more than 10%

4. Japan's Panasonic servo system provides power, stable and continuous power supply.

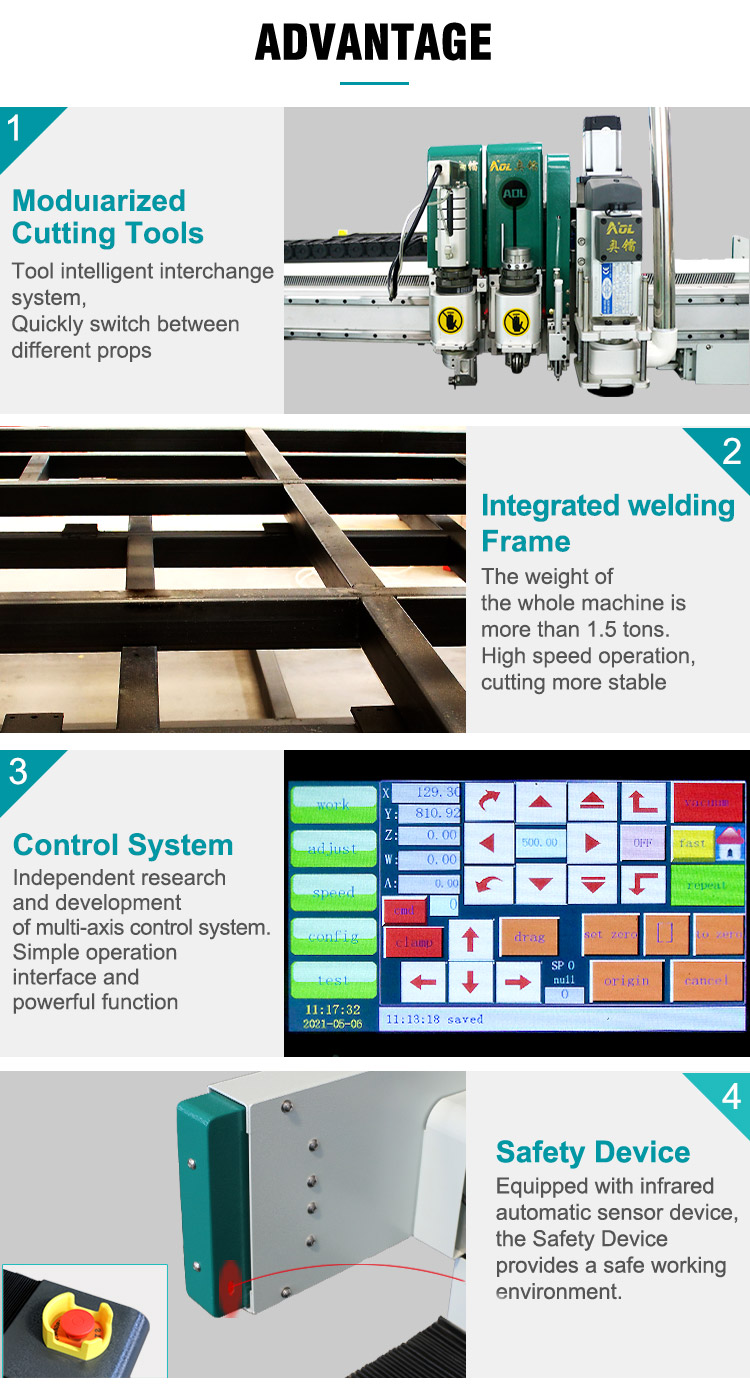

5. The machine can be equipped with a variety of knives for cutting materials in different industries, increasing the added value of the enterprise.

6. Infrared induction safety device ensures the safety of the operator during the high-speed movement of the machine, and at the same time avoids the loss of cutting materials.

7. Professional R&D team can provide assembly line supporting solutions

8. The anti-static system of the whole machine can protect the safety of personnel to the greatest extent.

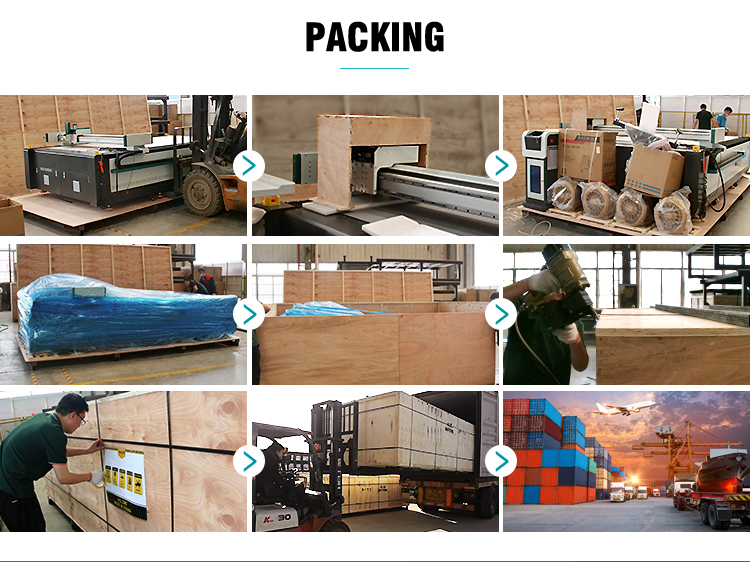

1. Outer packing: Standard sea export plywood box.

2. Inner packaging: stretchable film and plastic film to prevent moisture.

If you have special requirements, we can negotiate amicably. If you have any other questions or want to know more, please contact us and we will answer you as soon as possible!

AOYOO Media:

E-mail:info@aolcnc.com

phone:+86-18560162709

WhatsApp/Wechat:+8618560162709

YouTube:https://www.youtube.com/channel/UCctbMXFvompG-41Wecb1mpw

website:https://www.aoyoocut.com/

Facebook:https://www.facebook.com/AOYOOCUTTER