ASSURANCE

1. Manual drawing, non-standard cutting, low efficiency

2. The version is complicated, the types are difficult to manage, and it is easy to wear

3. Manual discharging takes time, wastes materials, and increases costs

4. Professional cutting workers have high salary and high recruitment difficulty

5. High risk factor of manual cutting

6. Order requirements are getting higher and higher, and traditional laser cutting cannot meet

1. AOYOO CUT self-developed software can be imported with one key, and ordinary workers can work proficiently in 2 hours

2. Super marker master software, material utilization rate increased by more than 10%

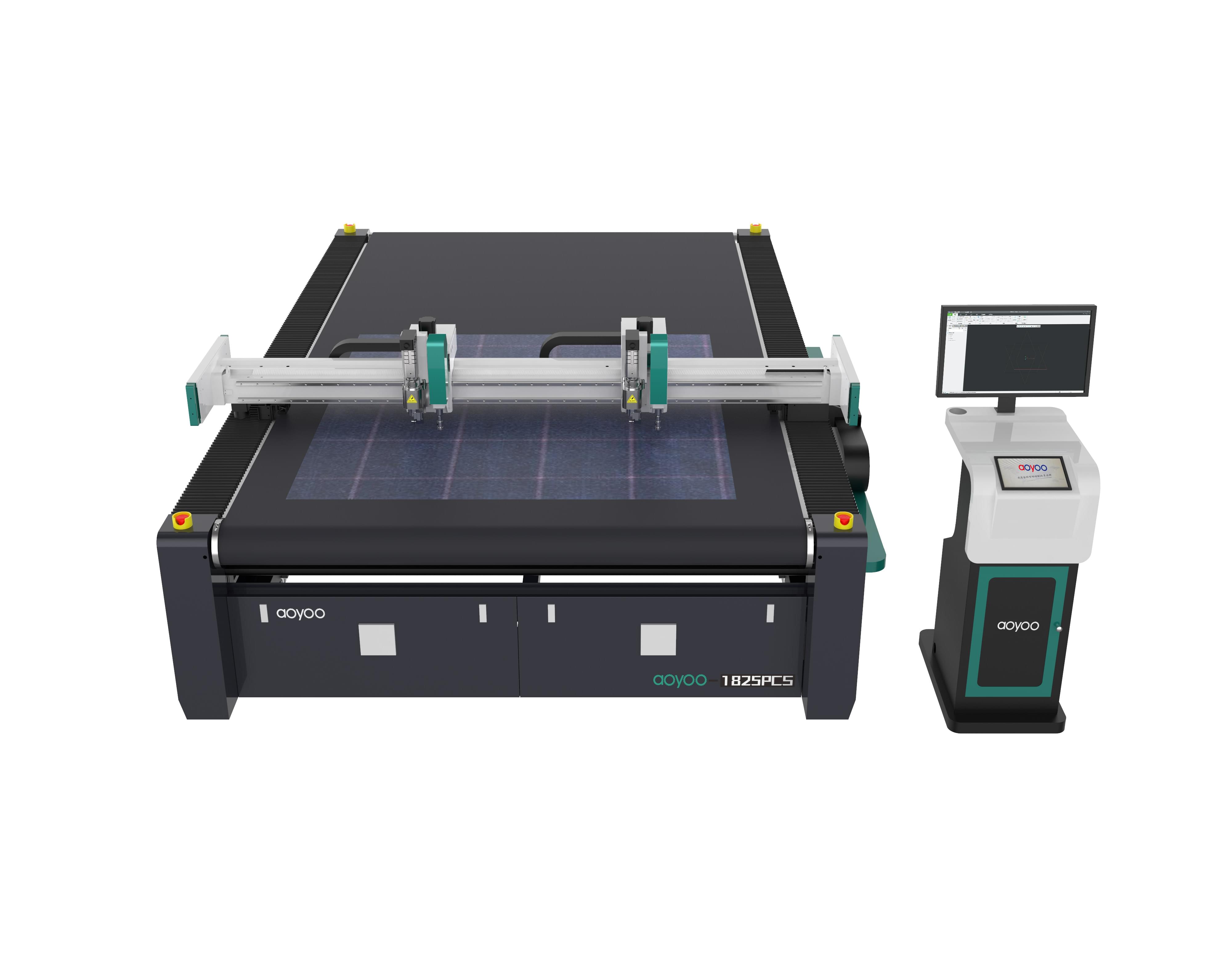

3. Use Taiwan linear guide drive system with accuracy ±0.1mm

4. Select Japanese Panasonic servo system to increase production efficiency by more than five times

5. AOYOO's unique tool exchange system, cutting, punching and marking are automatically completed

6. Automatic pulling and receiving, saving time and effort

7. Save more than 500,000 labor and raw materials every year, which greatly improves product competitiveness