ASSURANCE

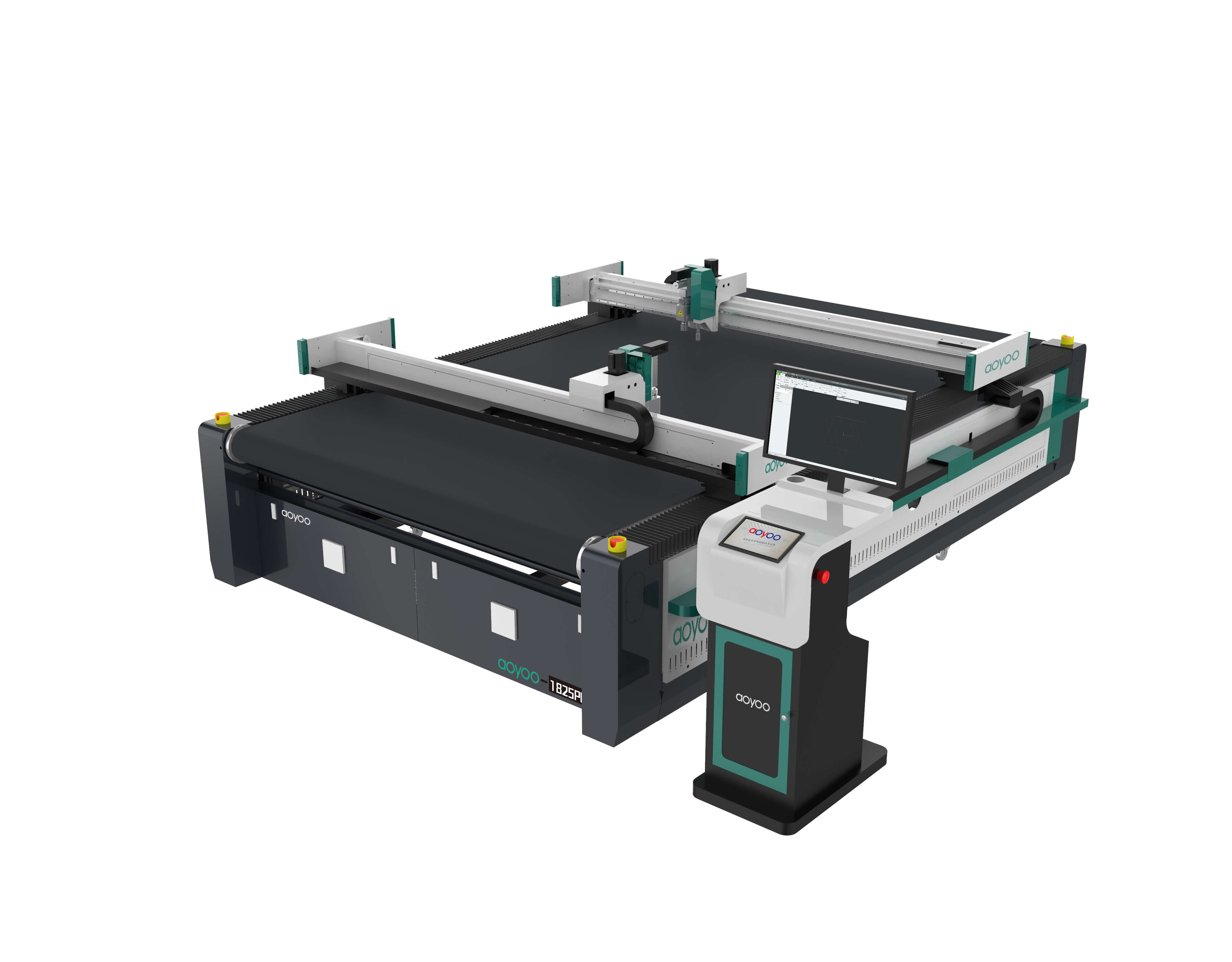

The advertising board cutting machine can cut a variety of advertising materials. Common advertising materials are: kt board, adhesive paper, plastic, foam board, leather glue, PE board, eva board, coated paper, corrugated paper, foam board, pearl cotton, spray Cotton, self-adhesive, blanket, acrylic, white cardboard, kraft paper, eva inner support, eva foam, eva plastic, etc., there are many materials, so the requirements for the cutting machine are huge.

The advertising board cutting machine has no smoke, no peculiar smell, no yellowing and scorching during the cutting process, avoids material waste, adopts blade cutting, has automatic loading and unloading system, automatic typesetting and automatic edge finding cutting system, cutting machine With a multi-axis control system, it can cut any shape, and the sweeping camera system can automatically identify the pictures on the material, realize automatic edge-finding and cutting, and the cutting error is extremely small.

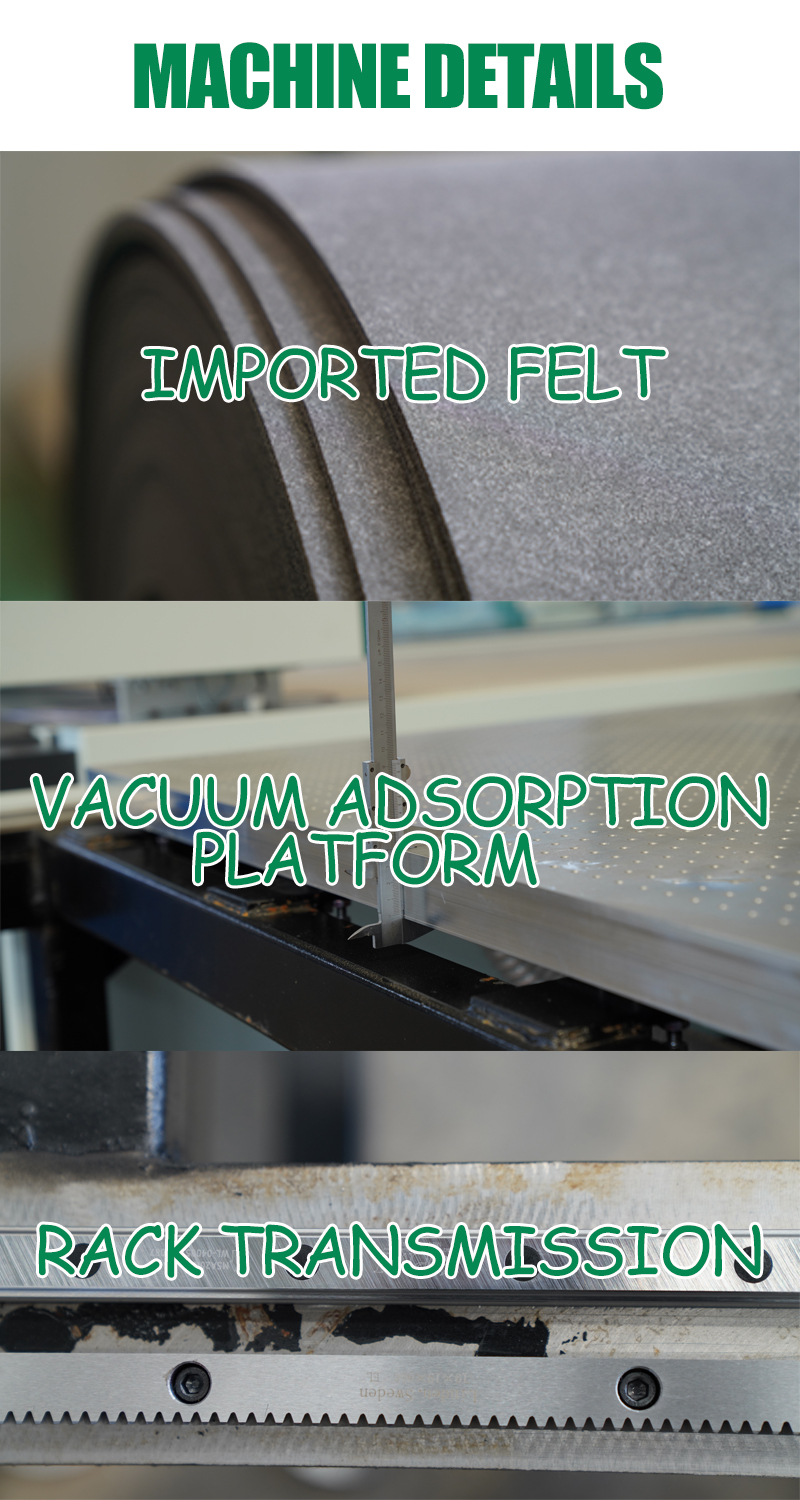

The advertising board cutting machine adopts integrated welding technology, the working table adopts aluminum-magnesium alloy adsorption platform, the bottom adopts vacuum adsorption system, vacuum adsorption in different areas, automatic feeding adopts the breathable high-density felt imported from the Netherlands, with high air permeability and high toughness, vibrating knife cutting The speed of the machine is up to 2300mm/s, the cutting accuracy is controlled within ±0.1mm, the cutting thickness is ≤50mm, and some materials can be cut at 70mm.

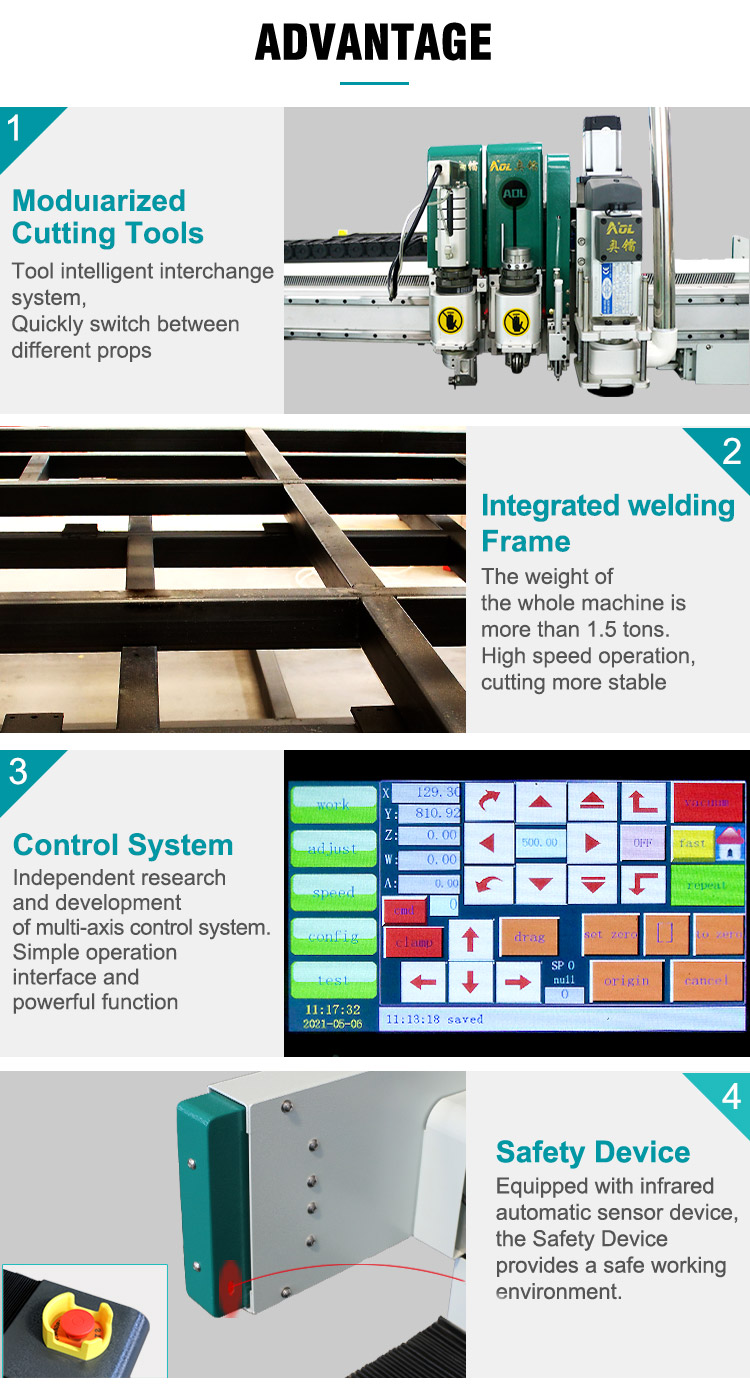

1. The table compensation function, the flatness of the table is detected by a high-precision distance detector, and the plane is corrected in real time through the software to achieve a perfect cutting effect.

2. High-performance multi-axis motion control system, easy maintenance

3. Independently develop and design CAM software, intelligent software compensates, optimizes cutting path, and improves production energy efficiency

4. It can realize automatic positioning and sleeve cutting of various materials, and can quickly and accurately cut various complex special-shaped graphics, which solves the shortcomings of inaccurate manual positioning.

5. Automatically detect the thickness of the material, no need to manually measure and then record the thickness data to the software

1. Adopt advanced high-end high-speed motion control system, which can realize dotted line, large pressure wheel indentation, full-cut cutting, half-cut cutting; V-CUT grooving of various materials; preset storage and digital fine-tuning of knife deep knife pressure ;Multiple positioning functions such as drawing and cursor can be configured, which can quickly cut all kinds of complex special-shaped graphics.

2. Equipped with vibrating knife, drag knife and other tools and drawing pen tools, it can cut and draw such as Chevron board, KT board, adhesive-backed board, corrugated paper, gray board paper, honeycomb board, white cardboard, kraft paper, red cardboard And other flexible materials and acrylic, PVC and other hard materials.

3. The size of the machine table can be customized, the platform structure design is adopted, and the partition suction design is adopted, with super strong wind and strong suction.

4. Environmental protection, no pollution, accurate cutting, saving a lot of manpower and material resources

5. The infrared induction safety device ensures the safety of the operator during the high-speed movement of the machine, and at the same time avoids the loss of cutting materials.

6. The whole machine is dust-proof to reduce the equipment failure rate and prolong the service life of the equipment.

1. Outer packing: Standard sea export plywood box.

2. Inner packaging: stretchable film and plastic film to prevent moisture.

If you have special requirements, we can negotiate amicably

Our standard warranty period begins when delivery is complete. We provide you with a three-year warranty service and provide professional machine maintenance

Renewal maintenance of machine parts is sold to customers at the lowest price.

1) Three-year free warranty (except wearing parts), free inspection and maintenance of main parts.

2) Provide lifetime free technology upgrade service

3) Wearable parts (eg blades, bench covers) are always available at cost when needed.

4) Free operation training in our factory. If there is not enough time, we will send detailed training videos.

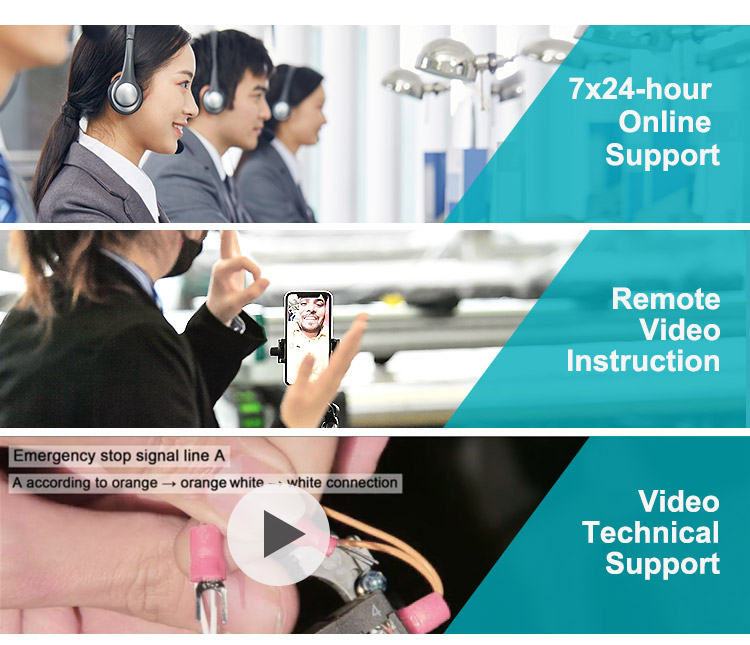

5) 24-hour online service, providing free technical support in different languages.

6) On-site technical support is available when needed.

7) AOYOO accepts unreasonable returns within 7 days after receiving the goods.

Email:info@aolcnc.com

phone:+86-18560162709

WhatsApp/Wechat:+8618560162709

YouTube:https://www.youtube.com/channel/UCctbMXFvompG-41Wecb1mpw

website:https://www.aoyoocut.com/

Facebook:https://www.facebook.com/AOYOOCUTTER

If you still want to know more, please contact us, we will answer you in detail!