ASSURANCE

Automated carbon fibre composite cutting machine can speed up production times and reduce labour costs. Software can optimise use of material to reduce waste – an important consideration for high priced reinforcements and prepregs. Designs can be quickly modified. Composite materials can be cut in complex patterns, quickly, accurately and consistently, and with better edge quality. Cut materials can be marked to make identifying parts (and kitting) easier.

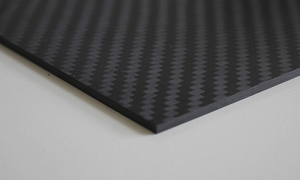

When it comes to loudspeaker enclosures, there are a number of advantages to having high strength paired with reduced weight, and this is an area where carbon fibre materials contribute significantly. Products employing composite technology benefit from a high stiffness-to-weight ratio, superior acoustic properties, lower weight and greater weather resistance compared to conventional enclosure materials. Multiple skins of carbon fibre layered over a honeycomb core form a highly rigid enclosure, with reduced parasitic cabinet resonance, increased low frequency output, and substantially less sound radiating from the back and sides of the enclosure.