ASSURANCE

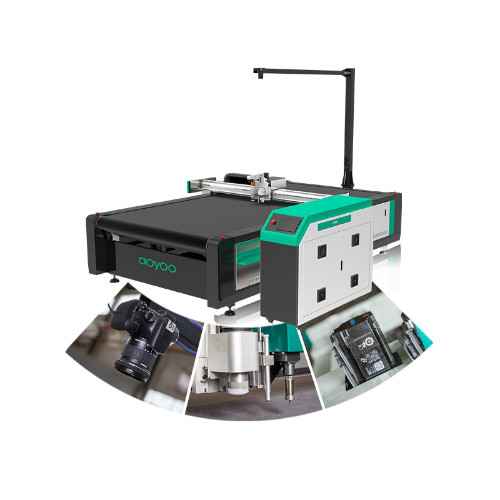

Operational steps of belt cutting machine leather

1. Prepare belt cutting machine leather and computer for operation.

2. Place hide onto the Intelliview inspection table, trims away unusable material, captures hide shape via digital camera, and inspects hide for blemishes. Blemishes are marked utilizing the mouse on the computer and the various shapes provided within the software.

3. Place hide onto the AOYOO belt cutting machine leather cutting surface, utilizing the proper background. Selects the unique code associated with that hide, and loads the cutting pattern into the machine's viewer. Places the hide under the outline of the hide being shown, ensuring all parts can be cut as shown on the viewer. Places plastic upon the machine, covering the hide, to hold it in place for cutting. Trims away unneeded plastic.

4. All cut parts are inspected for blemishes to ensure they are capable of being processed in down-stream processes. All internal cuts are to be free of leather.

5. Exercise safety procedures to prevent injury to oneself and coworkers, and to prevent damage to equipment.

6. Read and check off daily safety operation procedures before starting the machine.

7. Perform all daily cleaning/maintenance as required.

8. Perform all other duties as assigned.

If you didn't find the answer to your question, please Leave a message now for more details about belt cutting machine leather and we'll make sure you receive the information you need promptly.