ASSURANCE

TPU composite fabric is a composite material formed by compounding TPU film on various fabrics, and a new type of fabric is obtained by combining the characteristics of the two. Today, I will mainly introduce the application and cutting equipment of TPU composite fabrics.

There are two methods for TPU composite fabrics, one is called post-lamination: first make a TPU film and then glue it with the fabric, and the other is called online lamination: apply glue or no glue on the fabric, and directly put the TPU drool on the fabric. The fabric is made of TPU composite fabric or mesh. Generally, the factories that do post-lamination processing are not large in scale. There are many small factories in China. Most of them buy TPU films from external film factories, and only complete the process of gluing and laminating. In the process of post-lamination, high temperature and high pressure should be applied to the TPU film again. Improper process control will cause damage to the film and even small holes.

Common ones are inflatable life jackets, diving BC jackets, life rafts, inflatable boats, inflatable tents, military inflatable self-inflating mattresses, massage airbags, medical anti-decubitus mattresses and professional waterproof backpacks.

The cutting of TPU composite fabrics is different from the cutting of other ordinary fabrics, because the field of application of TPU composite fabrics requires that every step in the production process of this material needs to be very rigorous, and cutting, as an important process, also needs to be taken seriously. . There are three main ways to cut TPU composite fabrics. One is manual cutting. As we all know, manual cutting has been gradually eliminated by the society, with low efficiency and low precision; the second is punching and shearing. The precision of manual cutting, but the flexibility of punching is low, and a large number of molds need to be made; the third is to use a CNC cutting machine to cut TPU composite fabrics. This kind of cutting equipment perfectly solves the drawbacks of manual cutting and punch cutting, and is a must-have equipment for most manufacturers now.

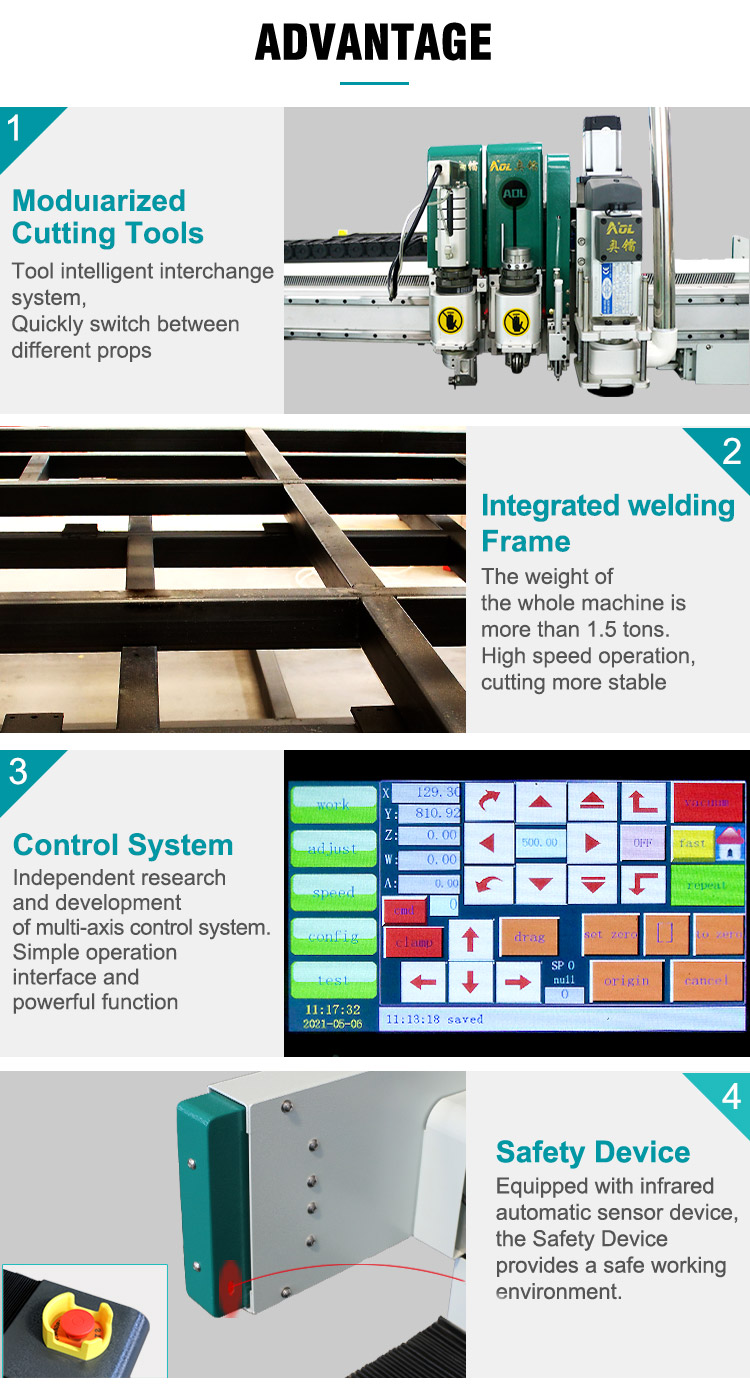

The TPU composite fabric cutting machine adopts the integrated welding technology of the fuselage. It does not need to make a mold or draw a plate. The computer can input the version and can be cut with one key. The operation is simple and flexible, and the equipment is highly intelligent, which meets the needs of the current cutting market. TPU composite fabric cutting machine cuts quickly and cuts more accurately. It adopts replaceable cutter head, which can replace vibrating knife full cutting, high-power active circular knife, punching knife, pneumatic knife, multi-layer knife and other tools, and replace different tools Applicable to glass fiber, glass fiber cotton, prepreg, carbon fiber, carbon fiber felt, boron fiber, aramid fiber, ceramic fiber, soft glass, PVC, leather leather, sponge composite leather, XPE material, silk ring foot pad, leather , soft glass, silicone, rubber materials and other composite flexible materials, and save materials and reduce costs.

For materials like TPU composite fabrics, it is recommended to use AOYOO-1625 vibrating knife automatic cutting machine for cutting, the advantages of TPU composite fabric vibrating knife automatic cutting machine:

1. Software intelligent typesetting function, the material utilization rate is as high as 95%.

2.2000mm/s high-efficiency cutting, 4-6 times faster than manual cutting.

3. Intelligent software compensation, the cutting precision is controlled within ±0.1mm.

4. High-strength honeycomb aluminum table top, imported felt conveyor belt, and large suction fan are used to ensure that the product has a super adsorption force when processing products.

5. The equipment is equipped with a safety sensor system and a mechanical anti-collision mechanism to prevent injury to personnel when the equipment is running at high speed.

6. The advanced tool quick change module has strong versatility. It is easy and quick to replace the tool, and it is more handy in the process of cutting different materials, and the operation and maintenance are easier and faster.

7. The automatic positioning and cutting of various materials is realized through high-precision distance detection sensors, which prevents the occurrence of inaccurate manual positioning, thereby improving the accuracy of sleeve cutting.

8. Realize personalized customization, one-click cutting mode.

Email:info@aolcnc.com

phone:+86-18560162709

WhatsApp/Wechat:+8618560162709

YouTube:https://www.youtube.com/channel/UCctbMXFvompG-41Wecb1mpw

website:https://www.aoyoocut.com/

Facebook:https://www.facebook.com/AOYOOCUTTER

If you want to know more about performance issues, please leave a message , we will have a professional staff contact you.