ASSURANCE

AOL CNC cutting machine is also called commercial professional cutting machine or automatic digital cutting machine. It has many names, but in the packaging industry as a whole, automatic CNC cutting machine is very suitable for cutting materials in the packaging industry.

The packaging industry is a relatively large area. It has many packaging materials of different materials, and the production of packaging cartons must be inseparable from the cooperation of cutting machines.

According to the material divided into cardboard, cardboard, wrapping paper

Cardboard also known as board paper, is a thick paper sheet made from various pulps and interwoven with fibers. The difference between cardboard and paper is usually distinguished by basis weight and thickness.

Generally, paper with a basis weight of more than 225g/㎡ and a thickness greater than 0.5mm is called cardboard.

Paper with a basis weight of 225g/㎡ or more is considered to be cardboard).

Cardboard for packaging, such as box cardboard, kraft cardboard, yellow cardboard, white cardboard, impregnated liner cardboard.

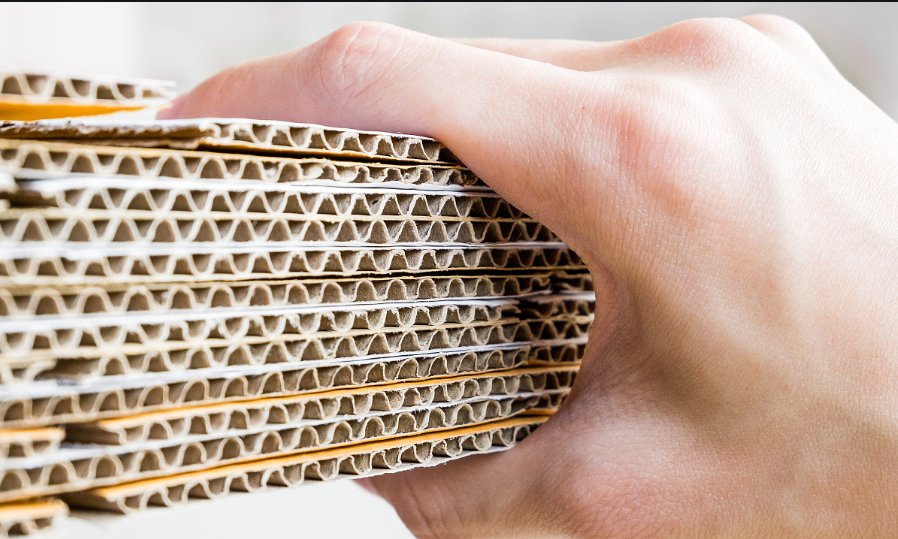

The most common are corrugated cardboard and honeycomb cardboard.

Cardboard is often used for product packaging and comprehensive finishing of goods. It has the characteristics of protecting products from deformation and damage

Corrugated cardboard is made by bonding face paper, lining paper, core paper and corrugated paper processed into corrugated corrugated paper.Corrugated cardboard can be processed into single-sided corrugated cardboard, three-layer corrugated cardboard, five-layer, seven-layer, and eleven-layer corrugated cardboard according to the number of processing layers.

There are two kinds of corrugated base paper width commonly used, 1600mm and 1450mm

The thickest corrugated cardboard is AAA and HK corrugated cardboard, the thickness is about 17mm, but it is not common. We generally use cartons less than 5mm

For this kind of hard cardboard material, we generally recommend using a vibrating knife with a pressing wheel.

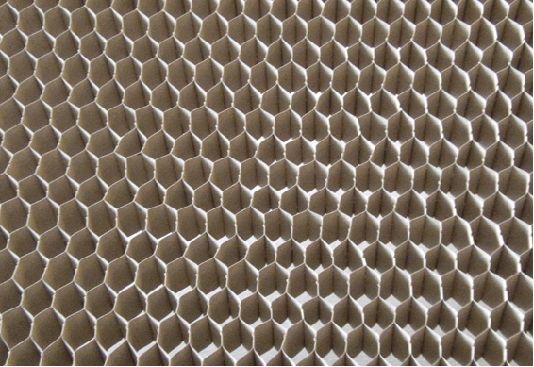

Honeycomb cardboard

Honeycomb paperboard is made according to the principle of natural honeycomb structure. It connects the corrugated base paper into countless hollow three-dimensional regular hexagons by glue bonding to form a whole force-bearing part-the paper core, and it is bonded on both sides. A new type of sandwich structure environmentally friendly and energy-saving material made of paper, honeycomb cardboard is popular in the market for its light weight, low price, high strength, and recyclability.

The common specifications of honeycomb paperboard thickness are: 12mm, 15mm, 20mm, 25mm, 30mm, 35mm, 40mm, 45mm, 50mm.

Cardboard is generally used in color box packaging, packaging paper bags, creative samples, business card printing, certificates, invitations, covers, monthly calendars, postal postcards, etc.

Cardboard can be roughly divided into three categories: white cardboard, white-bottomed whiteboard paper and gray-bottomed whiteboard paper. White-bottomed whiteboard paper and gray-bottomed whiteboard paper are also collectively called board paper.

The difference between white cardboard and cardboard

This is because white cardboard is made from raw pulp, while cardboard is made from waste paper pulp. Therefore, the cardboard of white cardboard is very strong, and the technical indicators are also quite strong. The paper made from waste pulp does not have good physical properties. Although it is relatively hard in hardness, its use is subject to many restrictions.

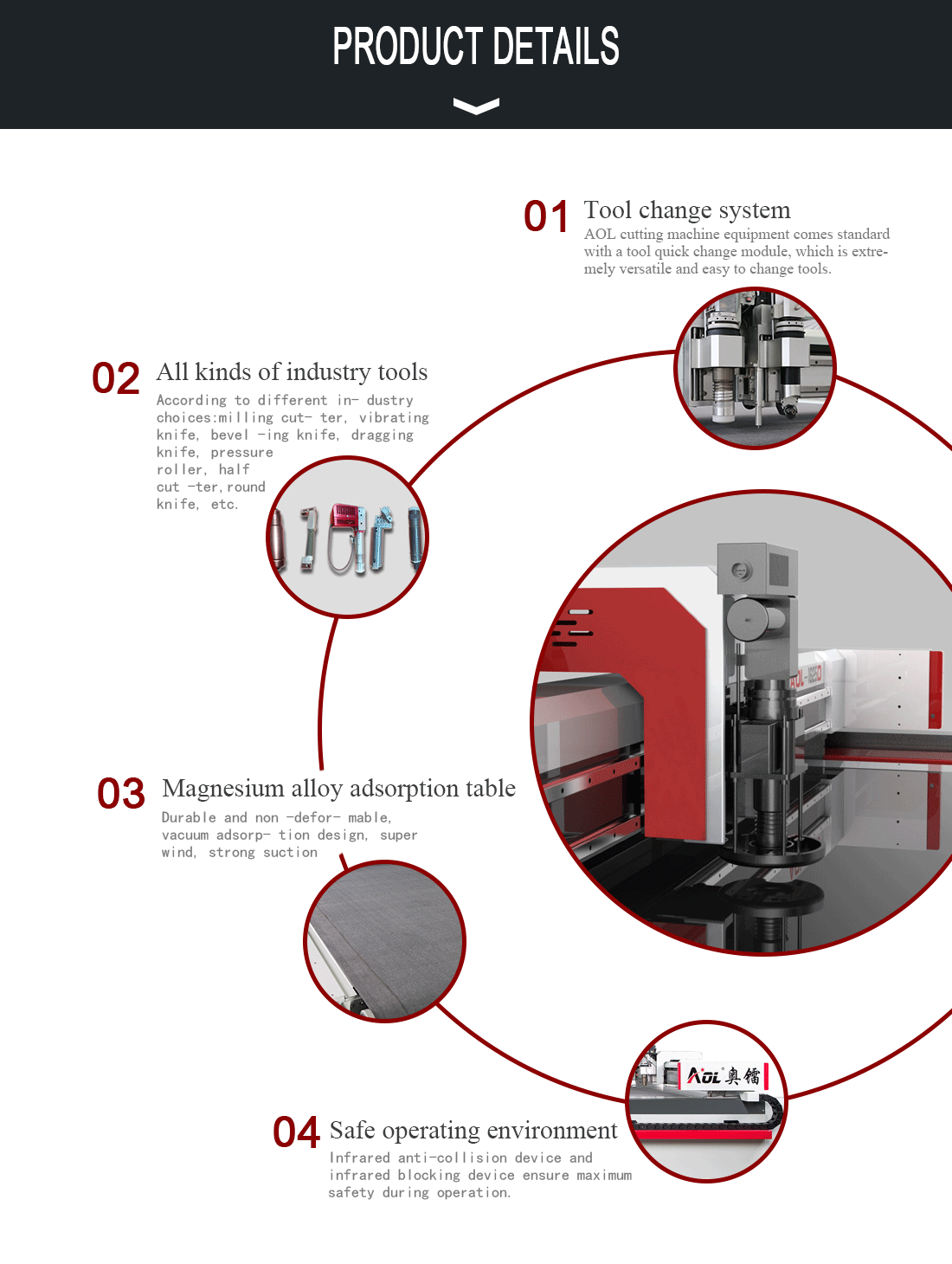

1. It adopts imported Panasonic servo motor and belt drive imported from Japan. The machine speed is 2000mm/S. In addition, it has strong anti-overload capability and can withstand a load of three times the rated torque. The performance of the whole machine is more stable, the service life is longer, and the cutting accuracy is higher.

2. Magnesium aluminum alloy vacuum adsorption table: AOL adopts advanced rolling table design, which can realize continuous automatic feeding. The design of a high-strength honeycomb aluminum adsorption table with an eight-zone independent adsorption structure. The table has good flatness and will not be deformed. It adopts 4mm thick imported felt conveyor belt, which has good air permeability, wear resistance and long service life.

3. High flexibility: The electric swing tool is very suitable for cutting flexible materials. With various blades, it is suitable for cutting materials of different hardness.

4. The machine is equipped with a small camera with automatic edge finding function, which saves more than 10% of materials.

5. Equipped with the tool quick change module, when cutting materials in the packaging industry, it can work with the press-wheel colleagues to greatly improve efficiency.

AOL CNC cutting machine is a professional cutting machine or a commercial cutting machine. It is a great help for businesses to improve efficiency. It saves a lot of resources in many ways. On the whole, it can save 20% of costs after one year of use. Whether it is labor, electricity, price, or service, it has great advantages.You can contact our professionals to provide you with a detailed price list.

| Technical parameters | AOYOO-1625 |

| Effective working area | 1600*2500mm |

| Multi-function cutting head | The combination of Multi-function cutting head and holders, be with full cut, kisscut, creasing wheel,v-cut and laser red light positioning functions, CCD positioning, Camera extract large contour to cut |

| Tools | Oscillating knife, Milling tool, pneumatic knife, V-cut, crease wheel, kiss cut, drag knife |

| Moving speed | 800-1500mm/s |

| Repeat precIsion | ±0.05mm |

| Interface | Enternet port |

| Control panel | LCD touch screen |

| Drive system | Imported servo motor, linear guid, synchronous belt, screw |

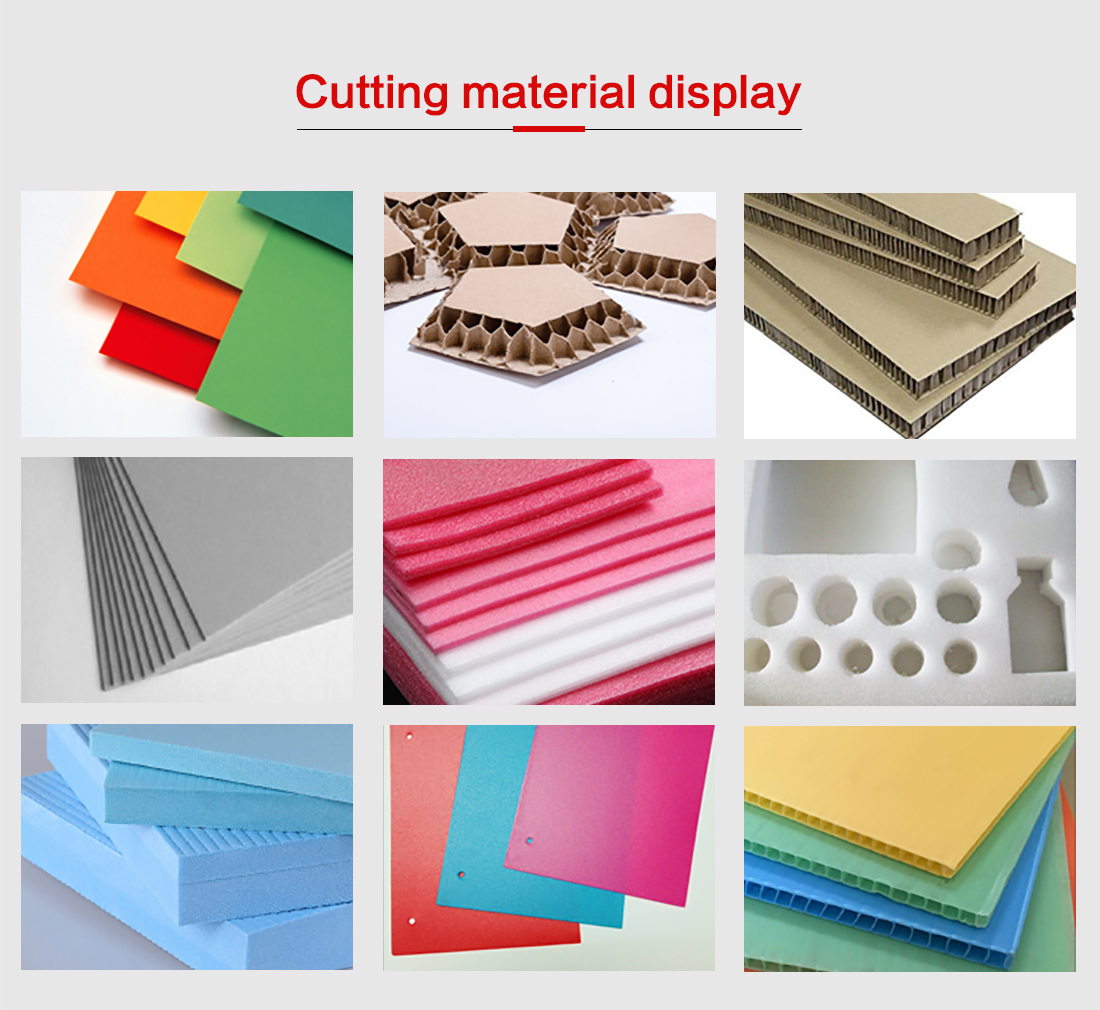

| Cutting material | Paperboard, grey board, KT board, pvc foam board, honeycomb board, car sticker, lamp piece, PP Adhesive material, printing cloth, banner cloth, all kinds of corrugated board, EPE foam, EVA, PVC board, acrylic board, thick foam and so on |

| Instruction system | HP- GL Compatible format |

| Rated power | 2. 2KW |

| Rated voltage | 220V |

| Cutting thickness | ≤50mm(According to different material) |

| Material fixed way | Vacuum adsorption |

| Auto feeding system | Acuum sucker adsorpting sheet |

AOL has been committed to professional industry material cutting solutions, if you want to know something,Here are detailed information. we have professional staff to answer you, our customers come from all over the world, we have successfully customized them A successful industry material cutting solution, you are welcome to contact us!